Waste gas suction and collection treatment device for steel casting workshop

A technology for a foundry and a processing device, applied in the field of iron and steel casting, can solve the problems of inconvenient cleaning of dust, lack of filtering and anti-blocking measures, and poor utilization of waste gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

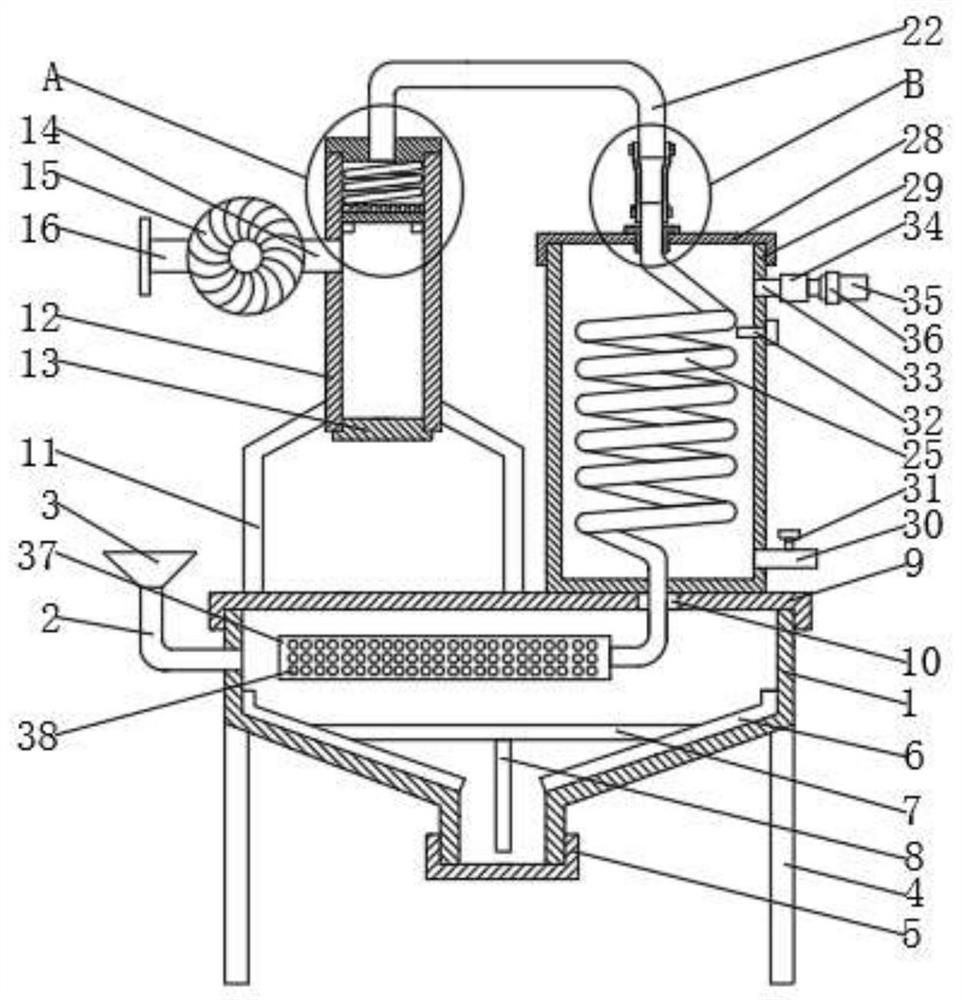

[0033] see Figure 1-6 , a waste gas suction and treatment device for iron and steel casting workshops, comprising an lye box 1, an L-shaped pipe 2 is fixedly connected to the left end of the lye box 1, and a funnel 3 is arranged on the upper end of the L-shaped pipe 2, and the lye box 1 The lower end of the bottom cover 5 is threadedly connected with a bottom cover 5, the lye tank 1 is slidingly connected with a scraper 6, the surface of the scraper 6 is fixedly connected with a support rod 7, and the lower end of the support rod 7 is fixedly connected with a driving rod 8, and the lye tank 1 The upper end is threadedly connected with a case cover 9;

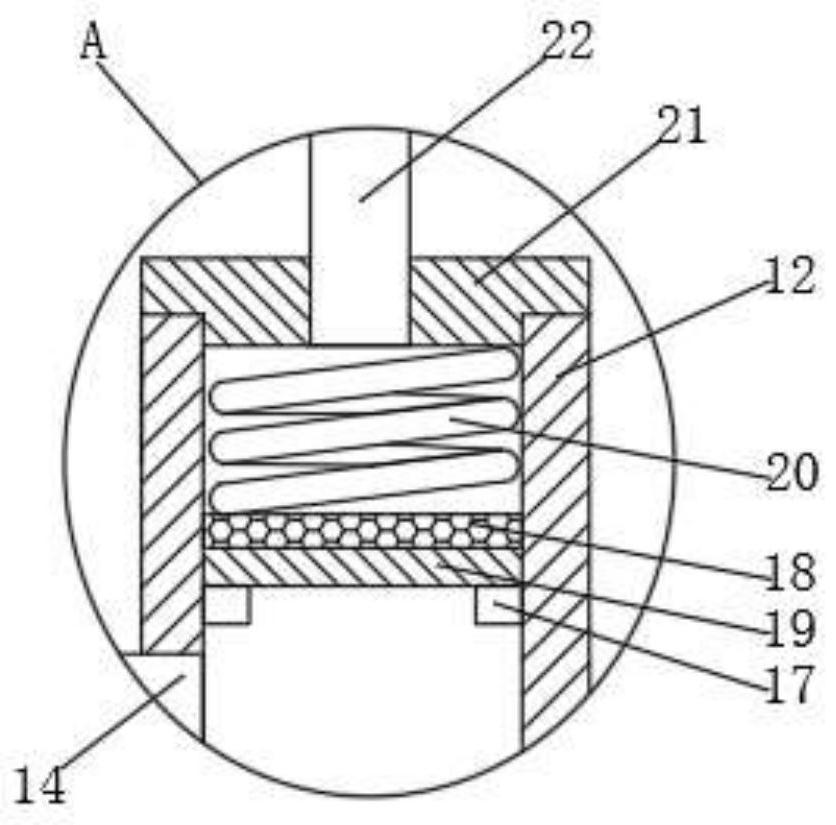

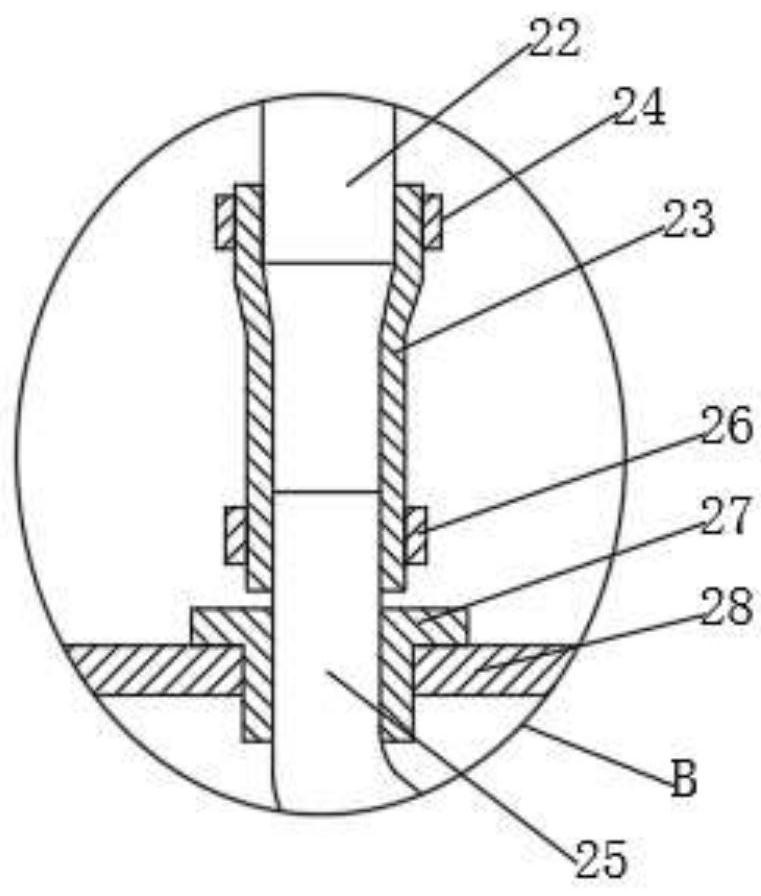

[0034] The upper end of the box cover 9 is fixedly connected with a connecting frame 11, the upper end of the connecting frame 11 is fixedly connected with a filter cartridge 12, the lower end of the filter cartridge 12 is threadedly connected with a lower cover 13, and the left side of the filter cartridge 12 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com