Dust remover and dust removal welding machine equipment

A technology for dust collectors and welding machines, which is applied in welding accessories, chemical instruments and methods, and separation of dispersed particles, and can solve the problems of energy consumption, dust removal equipment and other equipment with a large number and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

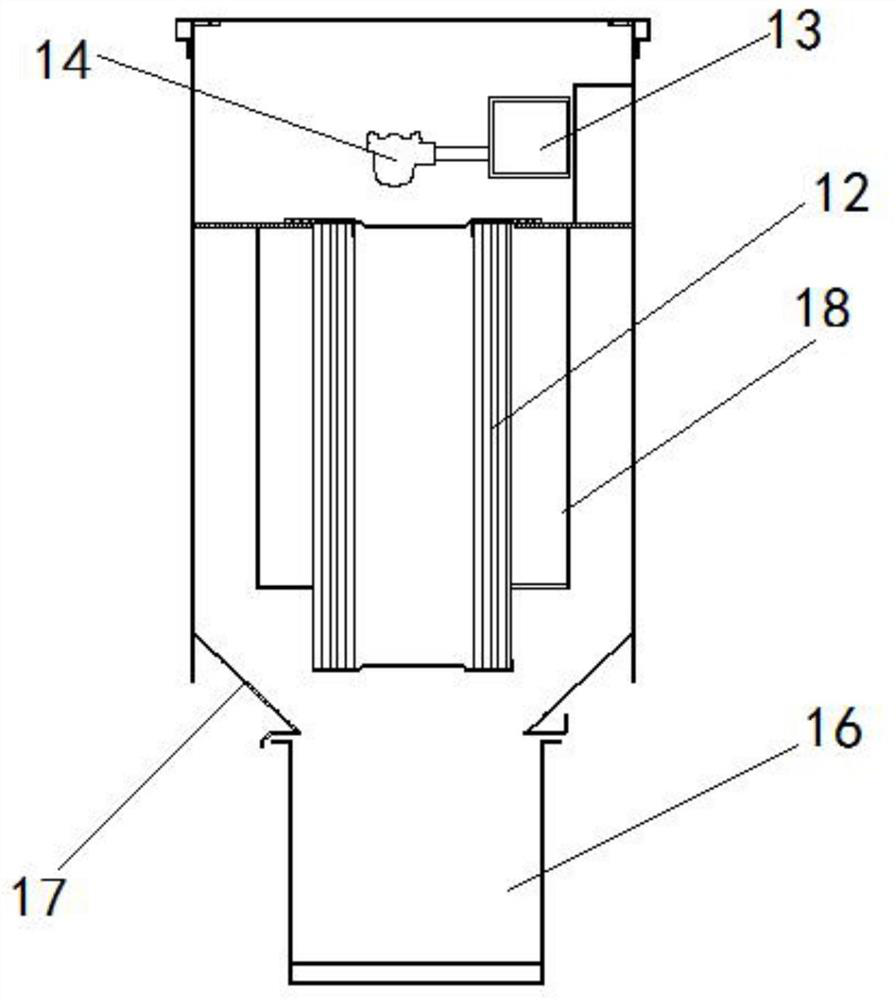

[0032] like Figure 1-Figure 7As shown, the present embodiment provides a dust removal welding machine equipment 100, including a dust removal box, a dust collection barrel 16, an annular cover 18, a filter cartridge 12 and a fan 11, and the filter cartridge 12 and the fan 11 are installed inside the dust removal box. The dust removal box can prevent the dust from being discharged to the outside during the treatment process, which affects the processing efficiency, and a dust inlet 15 is provided on the side wall of the dust removal box, so that the gas containing smoke and dust can be introduced into the dust removal box through the dust inlet 15. And to remove dust, the air inlet 111 of the fan 11 communicates with the inside of the filter cartridge 12, and the air outlet 112 of the fan 11 communicates with the outside world, so that when the fan 11 draws air, after the smoke-containing gas enters the annular gap, the large particles of smoke and dust and the ring The inner ...

Embodiment 2

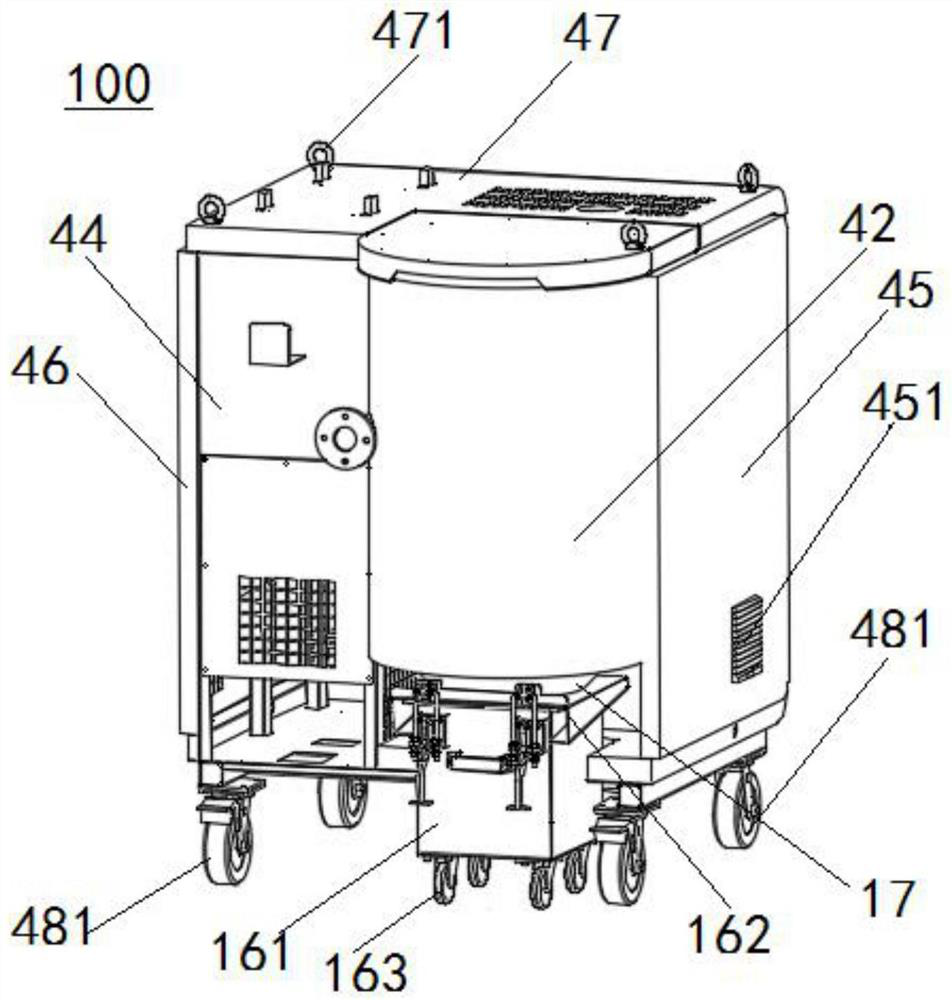

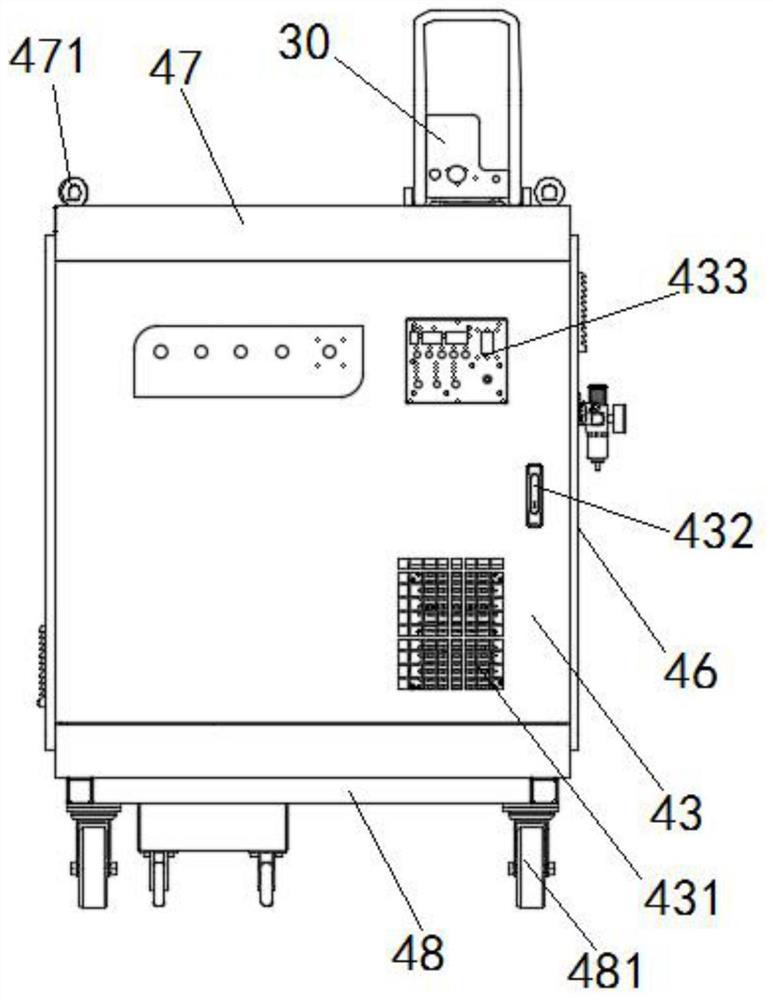

[0040] like Figure 2-Figure 7 As shown, this embodiment provides a dust removal welding machine equipment 100, including a housing 40, a wire feeder 30, a welding machine 20, and the dust remover 10 in Embodiment 1, the welding machine 20, the wire feeder 30 and the dust remover 10 are all installed in the housing 40 to realize the integration of welding and dust removal, improve the aesthetics of the equipment, and process the smoke and dust generated during the welding process of the welding machine 20 through the dust collector 10, thereby avoiding pollution of the environment and ensuring the health of the staff , the wire feeder 30 is used to deliver welding wire to the welding machine 20, the welding machine 20 is connected with an environmental protection welding torch, the environmental protection welding torch is located outside the housing 40, and the environmental protection welding torch is used for welding work, the suction nozzle of the environmental protection w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com