Preparation method of friction stir brazing of composite pipe/pipe and composite plate

A friction stir and brazing technology, used in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve problems such as inability to obtain firm joints, and achieve the effect of suppressing IMC and thermal stress, reducing thermal expansion coefficient, and expanding application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

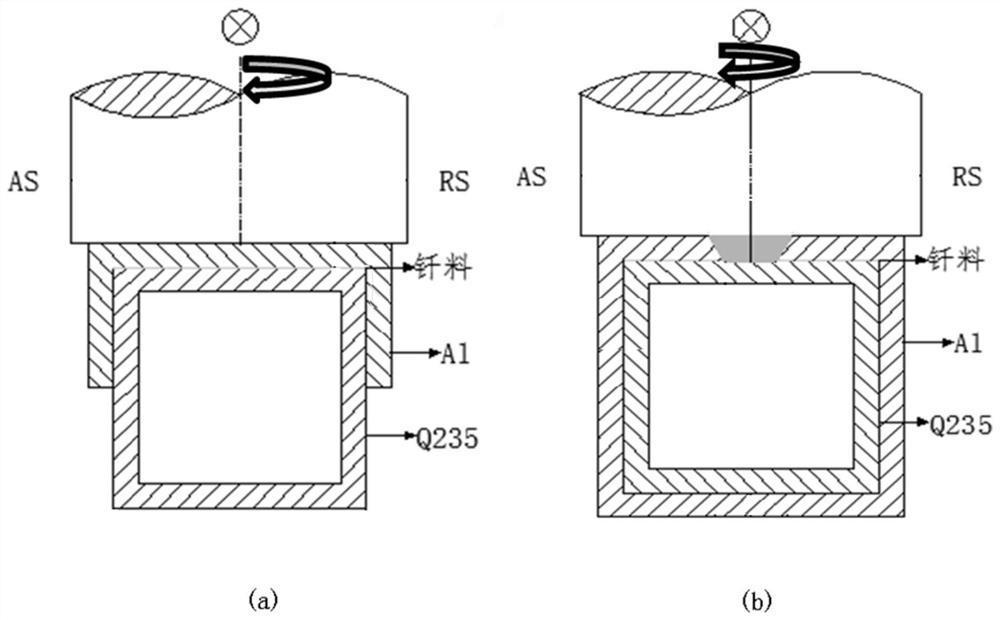

[0055] (1) Process design

[0056] Based on the smooth periphery of the square tube base material, it can theoretically form a large area of contact friction with the shoulder of the friction stir welding tool (stirring head), which is expected to generate enough friction heat to melt the brazing filler metal and make the composite tube. Friction Brazing (FSB) Method The process of welding two pre-formed U-shaped claddings (eg, bent from aluminum sheet) to a square base pipe (eg, square steel pipe) to produce a single composite square pipe (eg, , aluminum-clad steel composite square tube).

[0057] The technological process of preparing a composite square tube by friction stir brazing mainly includes material preparation and assembly, and a welding process consisting of friction stir brazing without needles on both sides and friction stir bra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com