Wearable man-machine collaborative assembly holder for automobile front-end module assembly

A front-end module, human-machine collaboration technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of low flexibility of manipulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

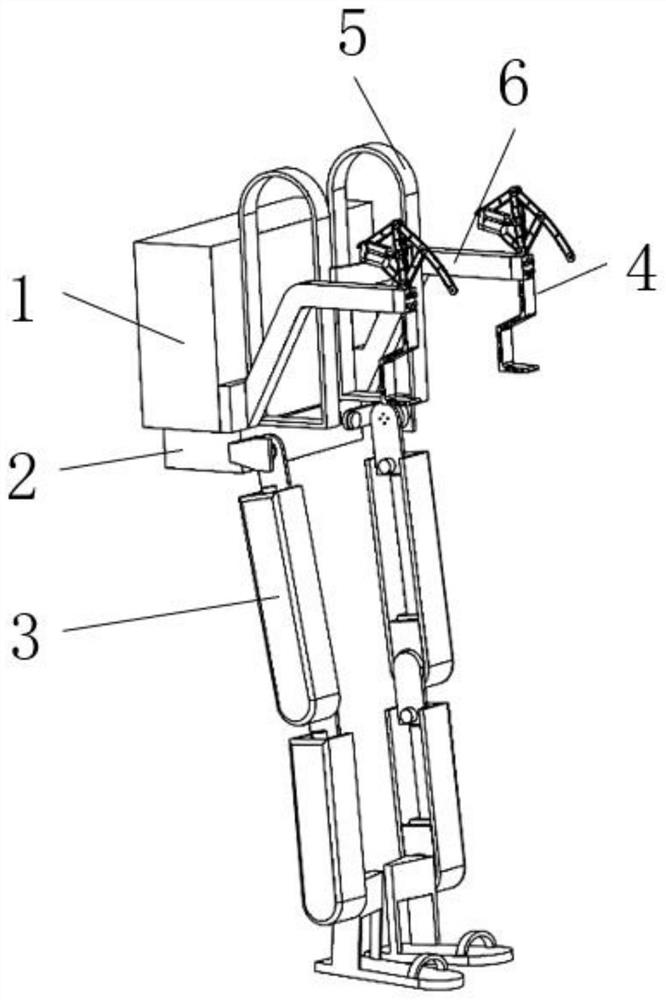

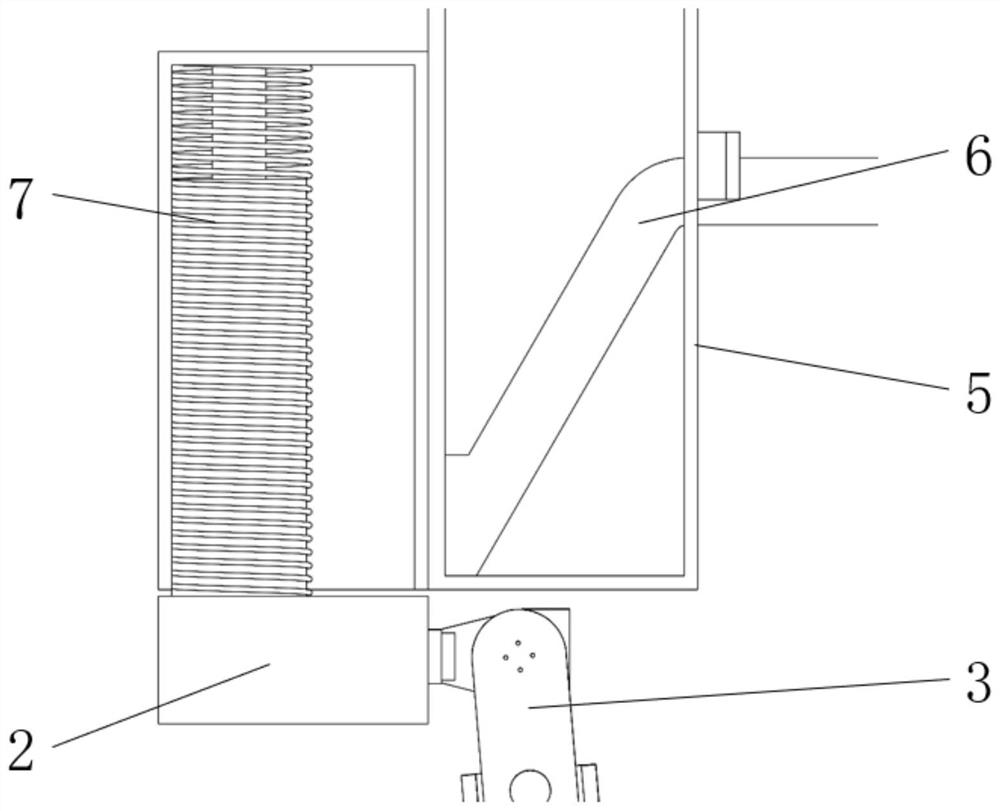

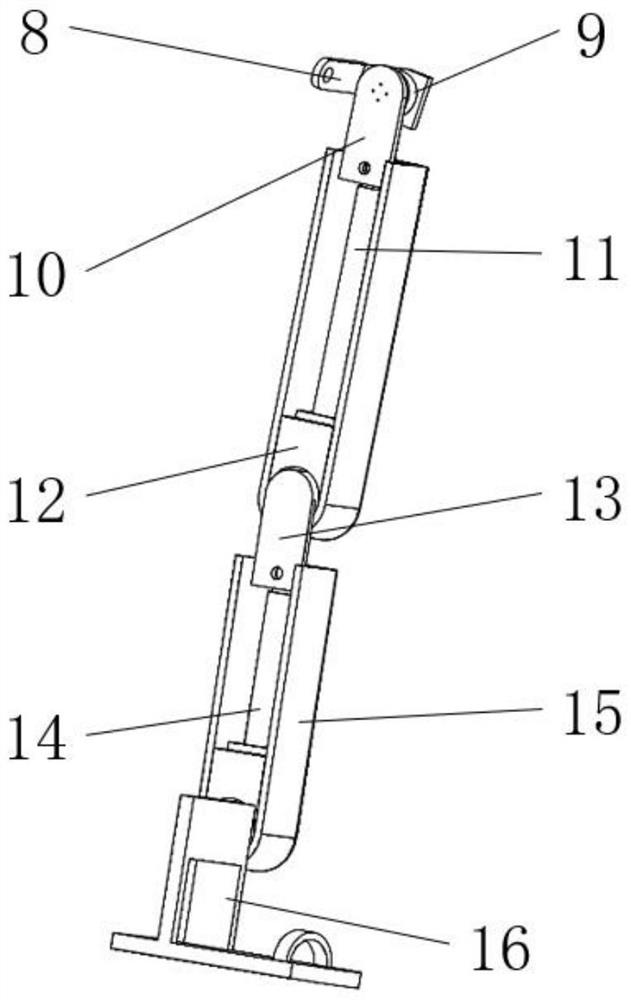

[0037] Please refer to figure 1 , with reference to Figure 2 to Figure 8 , the present application provides a wearable man-machine collaborative assembly gripper assembled with an automobile front-end module 30, which mainly includes a wearable backpack 1, a connecting platform 2, double shoulder straps 5, two sets of lower limb robots 3, two mechanical arms 6 and Two end grippers 4; among them, the connection platform 2 is fixedly installed on the bottom of the wearable backpack 1, and the double shoulder straps 5 are fixedly installed on the side of the wearable backpack 1, which can be worn by the user; at the same time, two groups of lower limb robots The tops of 3 are respectively hinged at the sides of the connecting platform 2 in parallel and spaced; the bottom ends of the two mechanical arms 6 are respectively fixed in parallel and spaced at the lower side of the wearable platform, and are on the same side of the wearable platform as the double shoulder straps 5 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com