Intelligent printing system for anti-counterfeiting element

A printing system and technology of anti-counterfeiting components, applied in printing, printing machine, rotary printing machine, etc., can solve the problems of position deviation of anti-counterfeiting component printing, difficulty in commodity identification, and inconvenience in commodity identification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

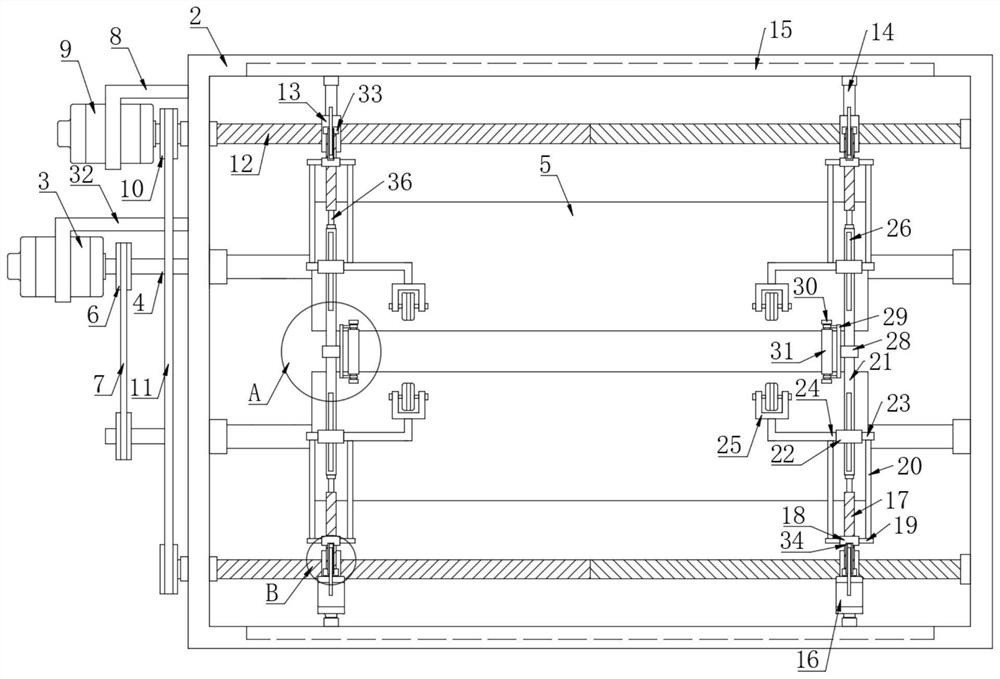

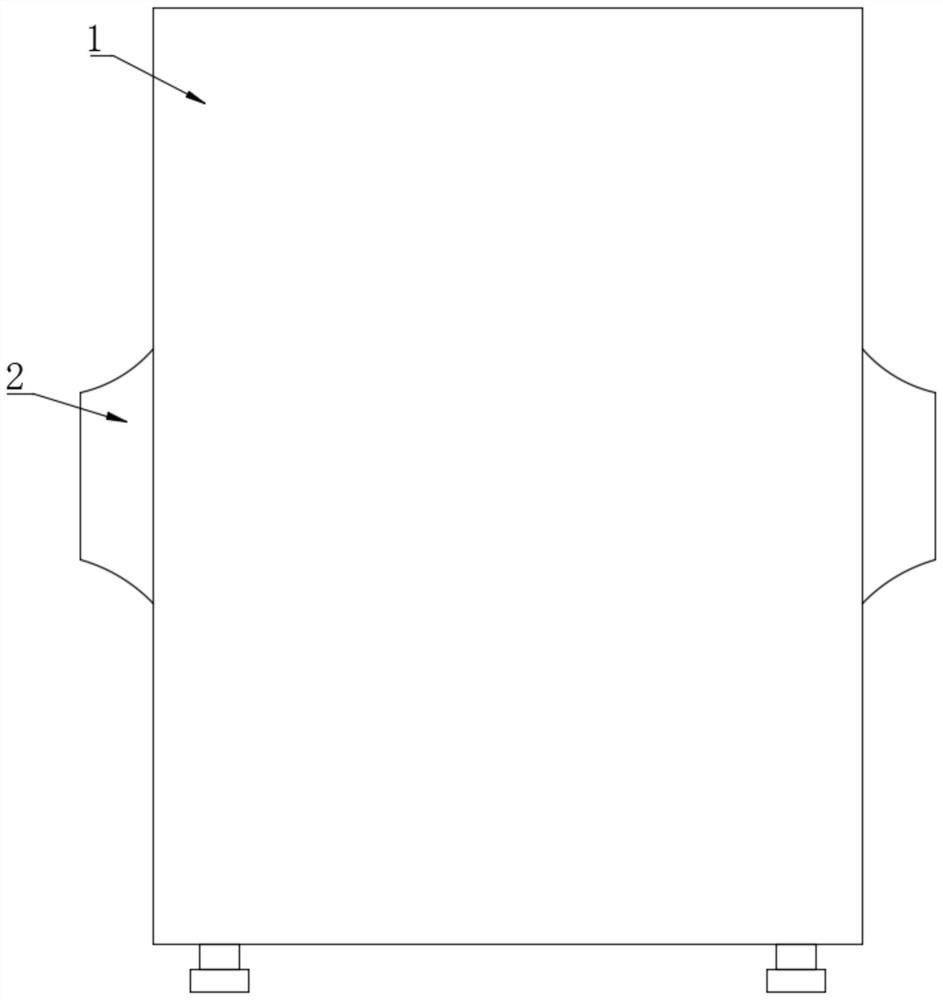

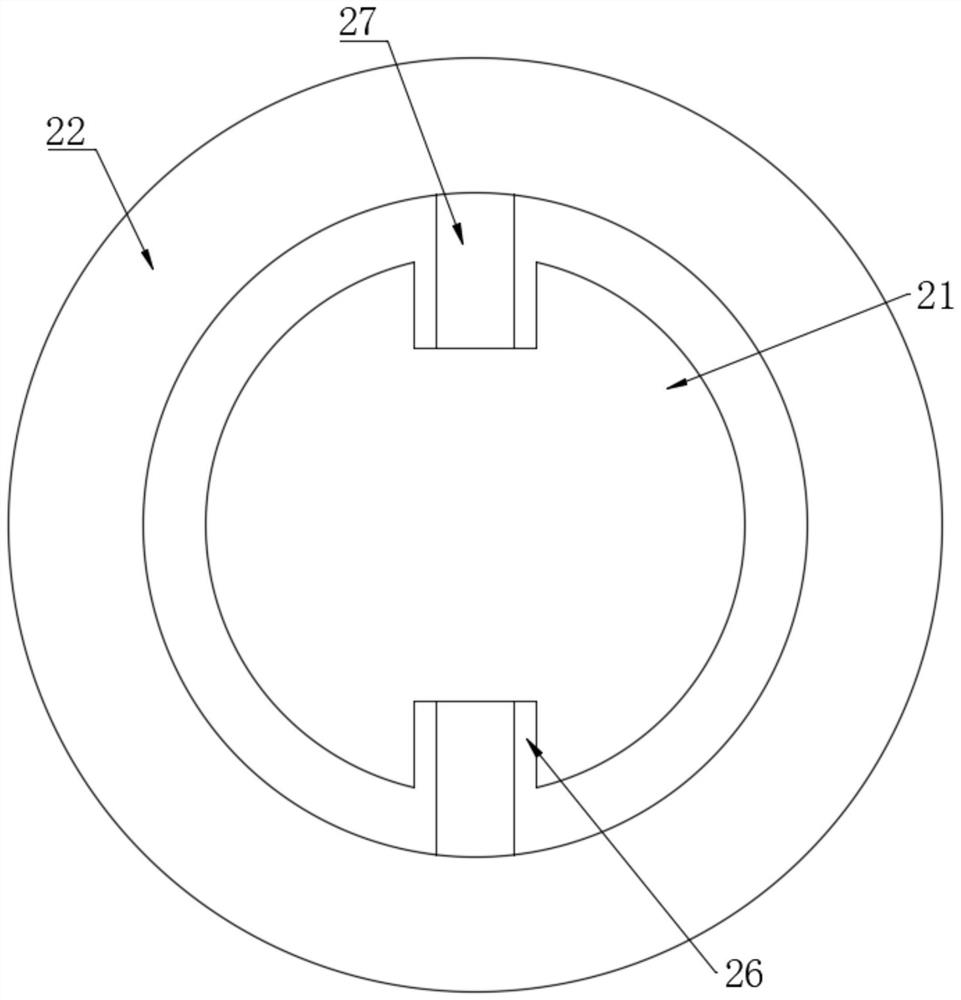

[0030] see Figure 1-5 , an intelligent printing system for anti-counterfeiting components, including a body 1, a printing chamber 2 is arranged inside the body 1, the front and back of the printing chamber 2 extend to the outside of the body 1, and the inside of the printing chamber 2 is symmetrically rotated and connected to a position close to the middle. The first rotating rod 4, the left end of the first rotating rod 4 extends to the outside of the printing chamber 2, and the left end of the first rotating rod 4 above is fixedly connected with the first motor 3, and the outer side of the first motor 3 is fixedly provided with the first motor 3 Two mounting brackets 32, the second mounting bracket 32 is fixedly connected with the side wall of the printing chamber 2, the outer wall of the first rotating rod 4 is fixedly provided with a printing roller 5, and the outer walls of the two first rotating rods 4 are fixedly arranged at a position close to the left end. The firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com