High-flow needle-free rubber valve connector and assembling method thereof

A technology of needle glue valve and large flow rate, which is applied in the field of medical supplies, can solve the problems of glue valve falling off and difficulty in assembling needleless joints, and achieve the effects of easy cleaning, avoiding drug backflow, and convenient production and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

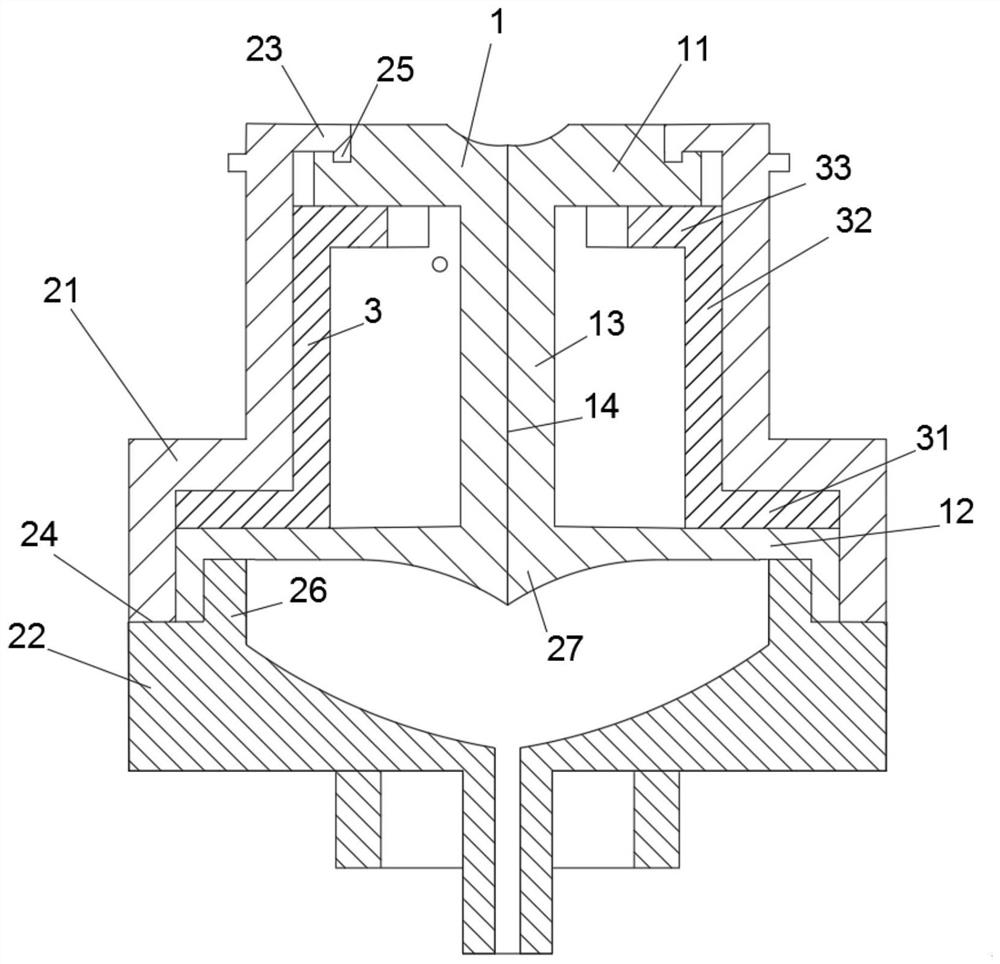

[0030] Such as figure 1 As shown, this embodiment provides a high-flow needle-free valve joint, including a valve 1 , a housing and a retaining ring 3 .

[0031] The glue valve 1 includes a small disc 11, a large disc 12 and a connecting block 13, one end of the connecting block 13 is connected to the small disc 11, and the other end is connected to the large disc 12, and the three are coaxial. The rubber valve 1 is provided with a liquid channel 14 that runs through the large disc 12, the small disc 11 and the connecting block 13 along the axial direction. The segments form duckbill valves 27 . The center of the top surface of the small disc 11 is provided with a guiding concave surface, the edge is provided with a card slot, and the edge of the large disc is provided with a downward fold.

[0032] The shell includes an upper shell 21 and a lower shell 22. The upper shell 21 includes an upper half and a lower half. The radius of the upper half is smaller than that of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com