An outer cantilevered solid stone line installation structure

A technology for installing structures and stone materials, which is applied in building construction, architecture, climate change adaptation, etc., can solve problems affecting the integrity of stone decorative lines, achieve the effects of improving connection stability, avoiding exposure, and improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

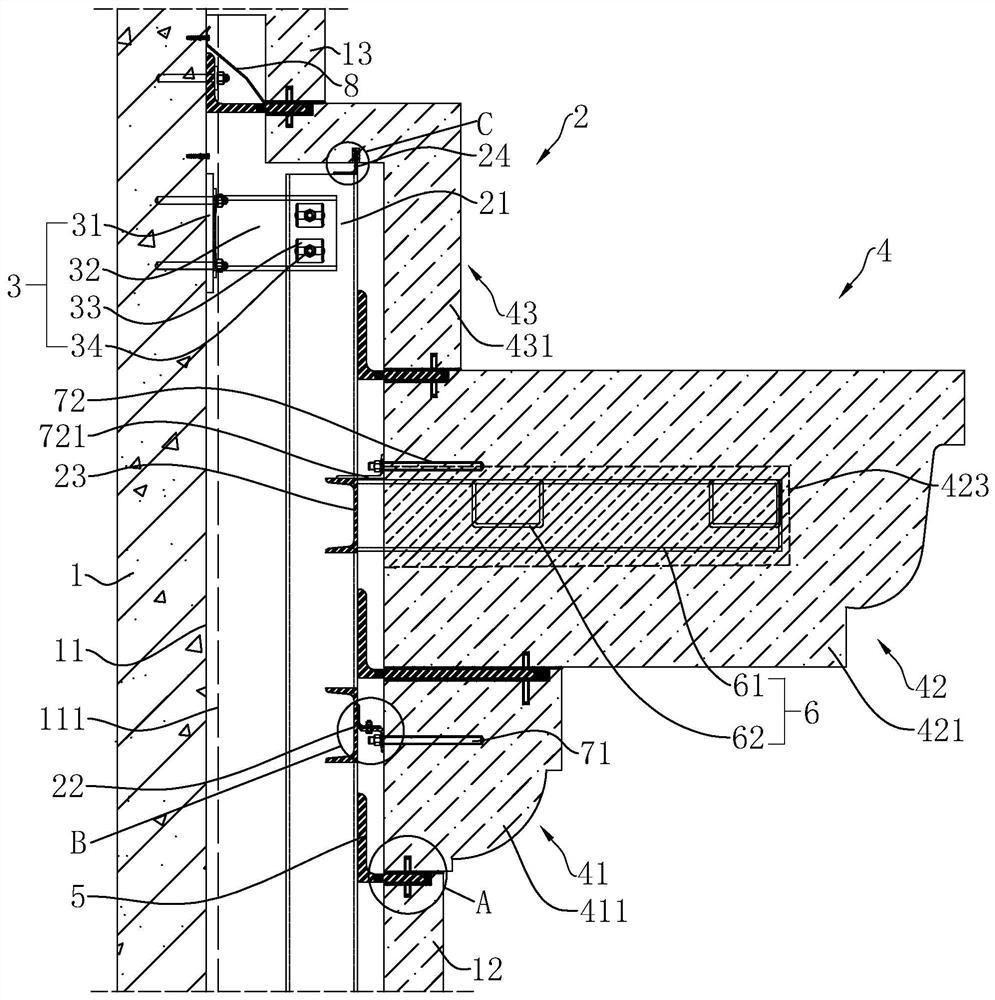

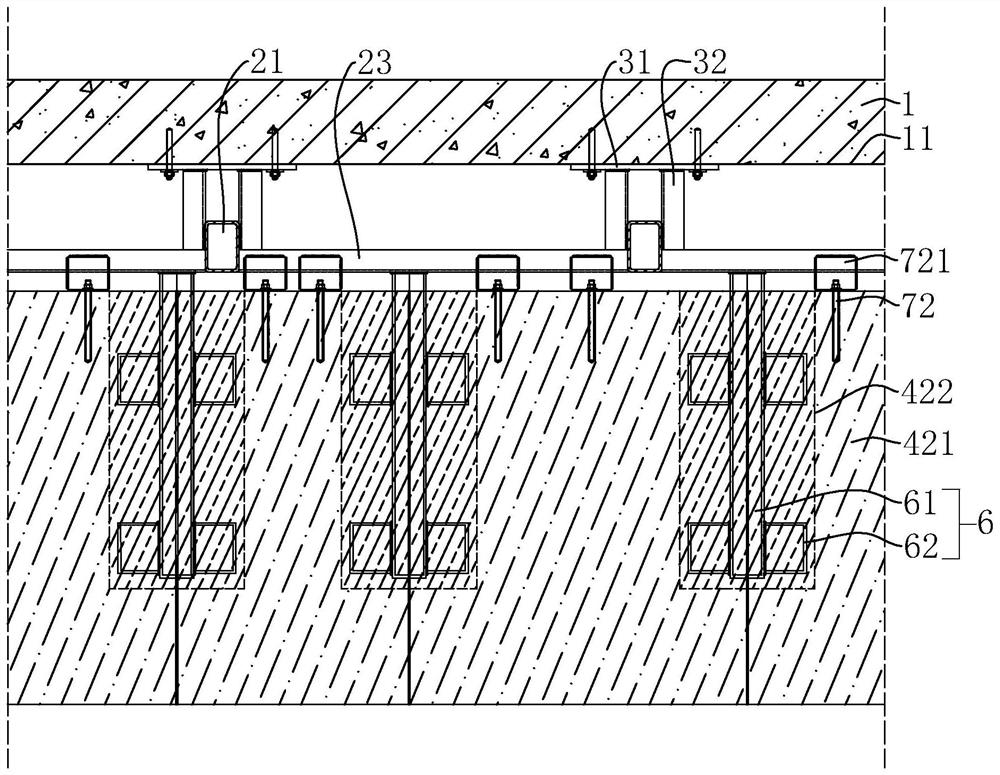

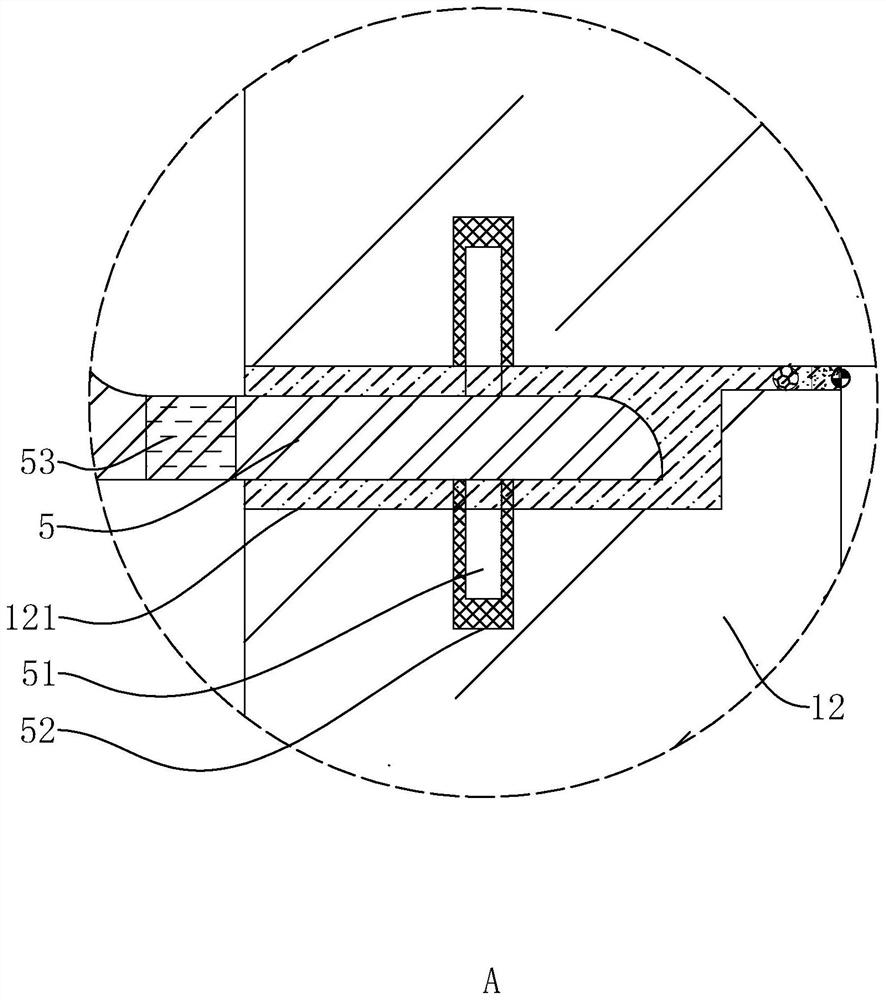

[0039] combine figure 1 and figure 2 , including the keel structure 2 fixed on the main structure 1 and the stone line 4 fixed on the side of the keel structure 2 facing away from the structural surface 11, the surface of the main structure 1 facing the keel structure 2 is the structural surface 11, and the structural surface 11 A waterproof coating 111 is provided.

[0040] The keel structure 2 includes vertically arranged connecting squares 21 , a plurality of connecting squares 21 are arranged at intervals along the horizontal direction parallel to the structure surface 11 , and the connecting squares 21 are fixedly connected to the main structure 1 through the connecting component 3 .

[0041] The connecting assembly 3 includes a fixing plate 31 that is fixedly connected to the structural surface 11 through anchor bolts. The fixing plate 31 is welded with two connecting channel steels 32 that are symmetrically arranged and have opposite openings. The opposite side walls ...

Embodiment 2

[0068] refer to Image 6 , an outer cantilevered solid stone line installation structure. The difference from the first embodiment is that two spaced fixing pieces are arranged between the upper supporting channel steel 23 and the second stone monomer 421, and the two fixing pieces are The positions correspond to the positions of the two mounting half-grooves 422, respectively. The fixing member is set as a fourth corner 9, and the fourth corner 9 is welded to the top end face of the upper support channel steel 23.

[0069] The fourth corner 9 is welded with a liquid injection pipe 10 arranged along the length direction of the supporting square pass 61. One end of the liquid injection pipe 10 extends into the installation half groove 422, and the liquid injection pipe 10 is located above the limit square pass 62. The end of the liquid injection pipe 10 facing away from the fourth corner yard 9 extends between the two limiting square passages 62 , and the liquid injection pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com