A cement-based anti-corrosion spraying material applied to steel chimneys and its preparation method

An anti-corrosion spraying, cement-based technology, applied in the field of chimney anti-corrosion, can solve the problems of cement-based coating structure being easily damaged, poor wear resistance of foamed glass bricks, insufficient strength and density, etc., to solve the problems of high cost, avoid corrosion, and smooth appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

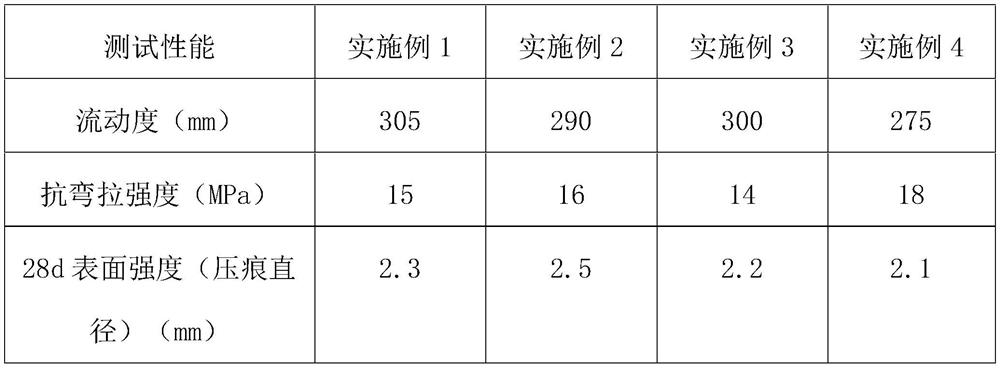

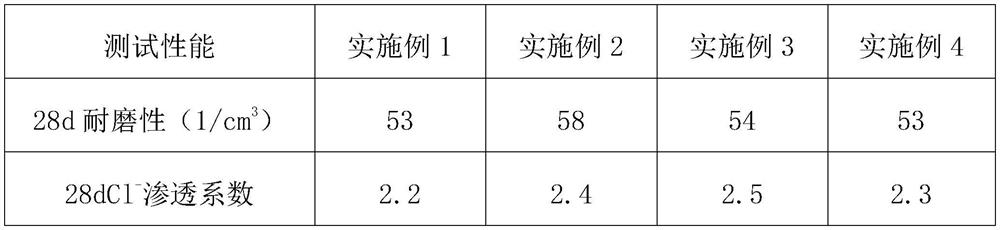

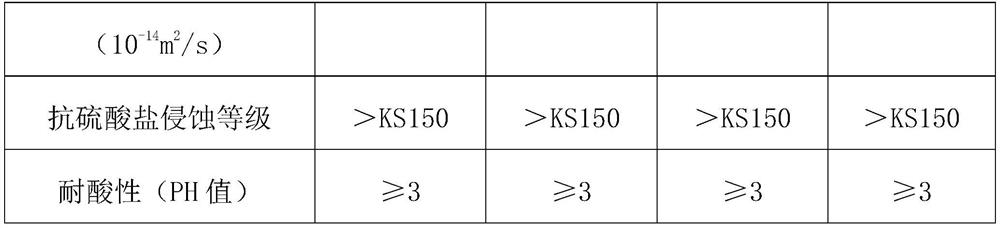

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned cement-based anticorrosion spraying material applied to steel chimneys comprises the following steps:

[0039] The step of preparing the premix: pour the cement, silica fume, powdered coal, quartz powder and quartz sand into the mixer and stir for 1-10 minutes, and mix evenly to prepare the premix;

[0040] Steps for preparing the finished product: add 60%-80% formula quantity of water and water reducer to the premix, stir for 2-20min, then add formula quantity of tackifier, toughener, anti-corrosion agent, remaining water and The admixture is continuously stirred for 2-10 minutes to obtain a cement-based anti-corrosion spraying material applied to a steel chimney.

Embodiment 1

[0042] A cement-based anti-corrosion spraying material applied to steel chimneys, comprising the following components in parts by weight:

[0043] 50 parts of cement, 15 parts of silica fume, 8 parts of fly ash, 5 parts of quartz powder, 180 parts of quartz sand, 0.5 parts of tackifier, 15 parts of toughening agent, 8 parts of corrosion inhibitor, 5 parts of water reducing agent, 35 parts of water share.

[0044] The cement is P.O52.5 ordinary Portland cement. The specific surface area of silica fume is 17000m 2 / kg, SiO in silica fume 2 The mass content of silica fume 28d is 96%, and the activity index of silica fume 28d is 115%. Fly ash is superfine fly ash, and the specific surface area of fly ash is 1710m 2 / kg, the loss on ignition of fly ash is 2.6%, and the 28d activity index of fly ash is 96%. SiO in quartz powder 2 The mass content of the quartz powder is 95%, and the specific surface area of the quartz powder is 600m 2 / kg; the fineness modulus of quartz...

Embodiment 2

[0049] A cement-based anti-corrosion spraying material applied to steel chimneys, comprising the following components in parts by weight:

[0050] 100 parts of cement, 30 parts of silica fume, 22 parts of fly ash, 20 parts of quartz powder, 100 parts of quartz sand, 0.1 part of tackifier, 1 part of toughening agent, 0.5 part of anti-corrosion agent, 0.5 part of water reducer, 10 parts of water share.

[0051] The cement is P.O52.5 ordinary Portland cement. The specific surface area of silica fume is 18000m 2 / kg, SiO in silica fume 2 The mass content of silica fume 28d is 97%, and the activity index of silica fume 28d is 120%. The fly ash is superfine fly ash, and the specific surface area of the fly ash is 1700m 2 / kg, the loss on ignition of fly ash is 2.8%, and the 28d activity index of fly ash is 98%. SiO in quartz powder 2 The mass content of the quartz powder is 97%, and the specific surface area of the quartz powder is 650m 2 / kg; the fineness modulus of qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com