Laser cladding powder for preparing hard strengthened layer on surface of zinc pot roller shaft sleeve

A technology of laser cladding and zinc pot roll, applied in the direction of coating, metal material coating process, etc., can solve the problems of low hardness and easy wear of zinc pot roll bushing, improve the hardness and wear resistance, and prolong the use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The mass percentage of the main constituent elements of the iron-based powder is: 0.02%C, 16.5%Cr, 4%Cu, 0.5%Mn, 0.3%Nb, 4.57%Ni, 0.46%Si, the balance Fe, and the particle size of the powder is 20-55μm ; The mass percentage of the main constituent elements of the cermet powder is: 4% C, 11% Co, and the balance W, and the obtained particle size is 15-45 μm. The two raw material powders were evenly mixed with a three-dimensional powder mixer, wherein the iron-based powder accounted for 60% by mass, and the cermet alloy powder accounted for 40% by mass.

[0011] Cladding the mixed powder on the surface of the 316L stainless steel shaft sleeve, and carried out the microhardness test on the coating.

Embodiment 2

[0013] The mass percentage of the main constituent elements of the iron-based powder is: 0.02%C, 16.5%Cr, 4%Cu, 0.5%Mn, 0.3%Nb, 4.57%Ni, 0.46%Si, the balance Fe, and the particle size of the powder is 20-55μm ; The mass percentage of the main constituent elements of the cermet powder is: 4% C, 11% Co, the balance W, and the particle size of the powder is 15-45 μm. Mix the two raw material powders evenly with a three-dimensional powder mixer, wherein the mass proportion of iron-based powder is 50%, and the mass proportion of cermet alloy powder is 50%.

[0014] Cladding the mixed powder on the surface of the 316L stainless steel shaft sleeve, and carried out the microhardness test on the coating.

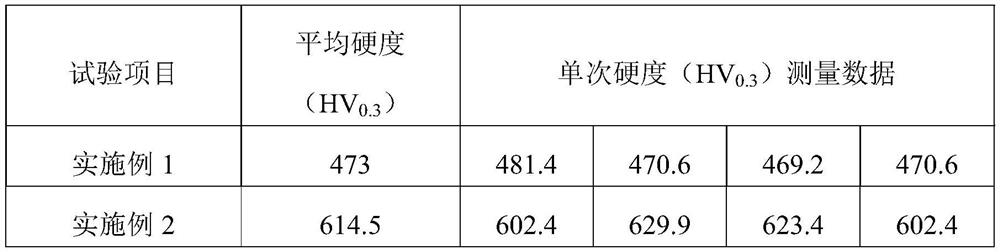

[0015] The product of embodiment 1, embodiment 2 is carried out microhardness measurement, and its result is as shown in table 1:

[0016] Table 1 Microhardness test results of the coating after laser cladding

[0017]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com