Patents

Literature

56 results about "Metal Ceramic Alloys" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The fusion of ceramics (porcelain) to an alloy of two or more metals for use in restorative and prosthodontic dentistry. Examples of metal alloys employed include cobalt-chromium, gold-palladium, gold-platinum-palladium, and nickel-based alloys.

Special cobalt-based metal ceramic alloy powder for optical fiber laser cladding

ActiveCN102650012AHigh hardnessImprove plastic toughnessMetallic material coating processesHigh energyAlloy

The invention discloses special cobalt-based metal ceramic alloy powder for optical fiber laser cladding, which is matched with characteristics of optical fiber laser. The special cobalt-based metal ceramic alloy powder contains the following components by weight percent: 1-2% of carbon, 1-2% of silicon, 2-4% of iron, 1.5-2.5% of nickel, 3-4% of molybdenum, 8-12% of chromium, 3-4% of tungsten, 13-17% of tungsten carbonate, 2-3% of calcium fluoride, 1-2% of silicon nitrate and cobalt for the rest. The metal ceramic alloy powder is specially applied to a cladding process of a high-energy optical fiber laser device, a metal ceramic cladding layer with high hardness, high flexibility and high corrosion resistance can be formed on the surface of a work die of a steel and iron basis material, and the cladding layer is compact in structure, has no defects such as air holes, cracks, shrinkage cavities and the like, and has excellent metallographic performance such as high hardness, high plasticity, flexibility and corrosion resistance, and the like; moreover, the process is convenient and the thermal treatment does not need to be carried out in advance and afterwards. The special cobalt-based metal ceramic alloy powder is particularly suitable for the surface treatment of the die and can greatly prolong the service life of the die.

Owner:CHANGZHOU TIANZHENG IND DEV CO LTD

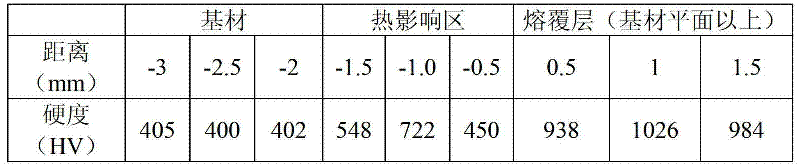

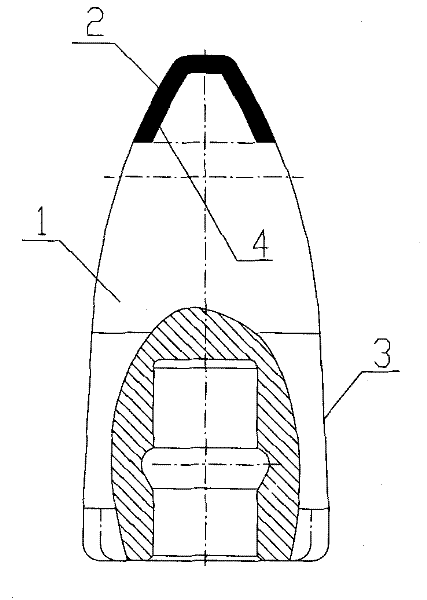

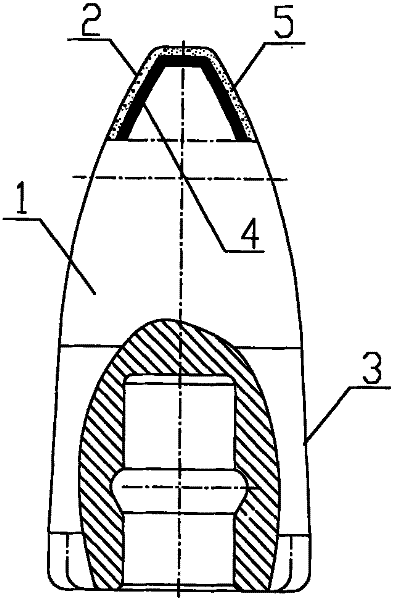

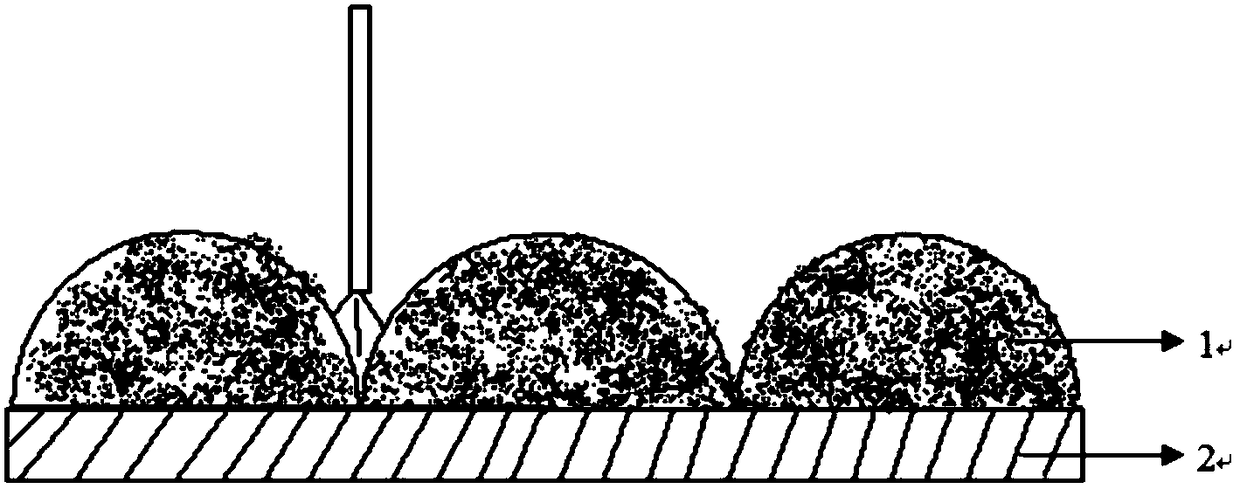

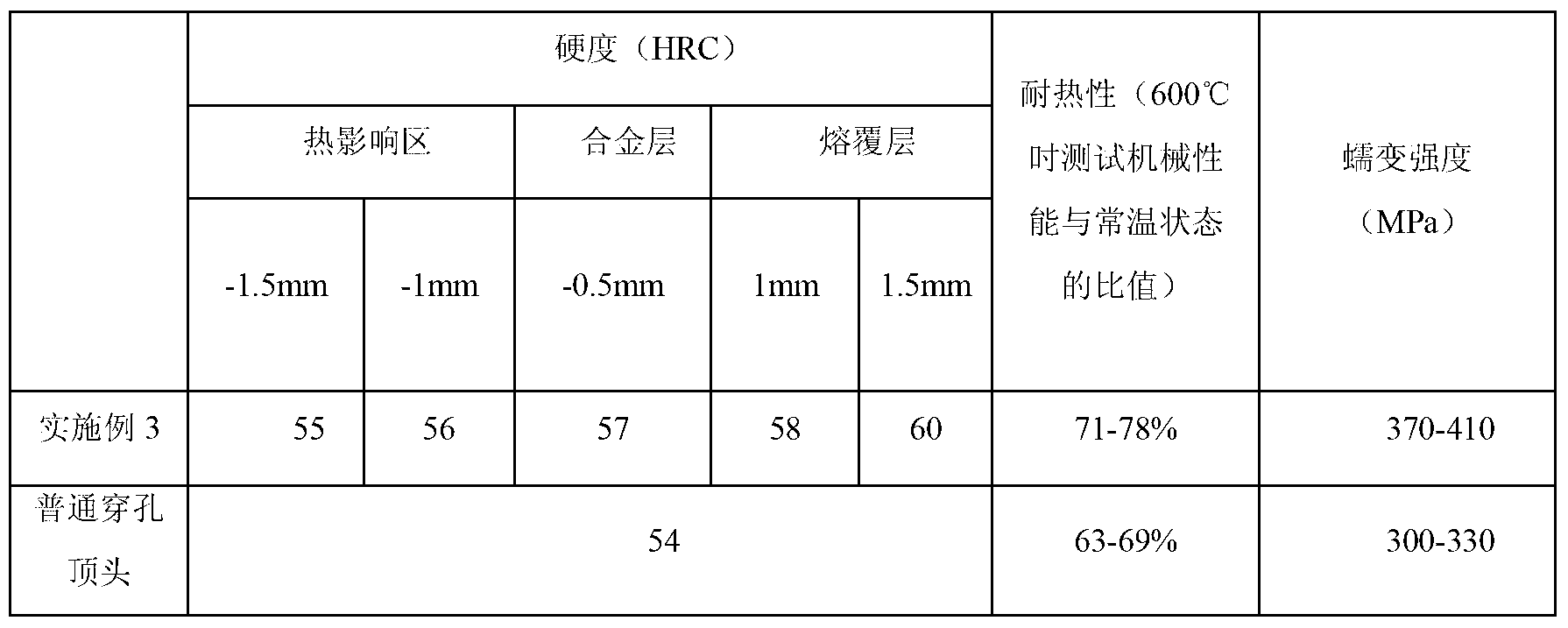

The Method of Overlay Welding Strengthening on the Surface of the Piercing Machine of Seamless Steel Pipe

InactiveCN102284777AGuaranteed rolling qualityEasy to useWelding/cutting auxillary devicesAuxillary welding devicesPresent methodAlloy

The invention discloses a method for strengthening the surface of the plug of a seamless steel pipe piercing machine by surfacing welding. The plug can be a casting or a forging. Firstly, the plug blank is subjected to initial machining, the head of the plug is cut to obtain the thickness of the surfacing welding, and the body parts are reserved for finishing. Allowance; for conventional flaw detection treatment, there are defects and rework treatment; use Ni-based, Co-based or cermet alloy materials to surfacing the head of the plug to form a surfacing layer and adopt the plasma arc surfacing method to ensure that the surfacing layer and the head of the plug The substrate is fully fused; the plug is turned to the final size requirement and flaw detection is performed, and defects are reworked; the surface of the plug is thermally oxidized to form an oxide film. The method can significantly increase the surface strength of the plug, improve the performance of the plug, reduce the production cost of the plug, increase the service life of the plug, and ensure the rolling quality of the seamless steel pipe.

Owner:SHANGHAI BAOSTEEL EQUIP MAINTENANCE CO LTD

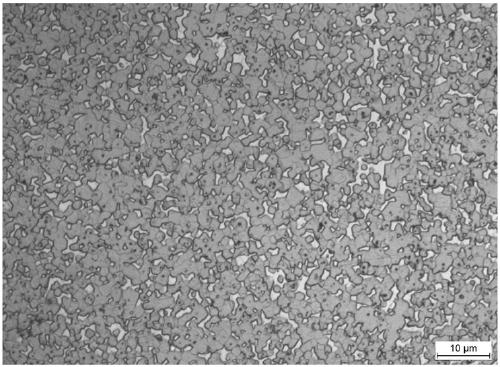

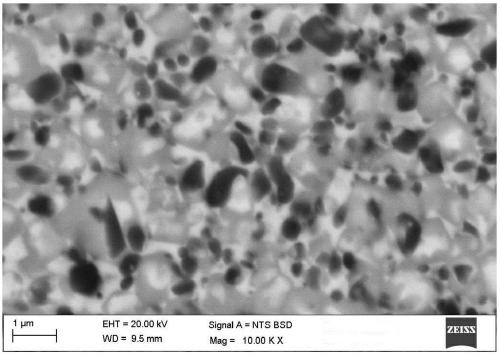

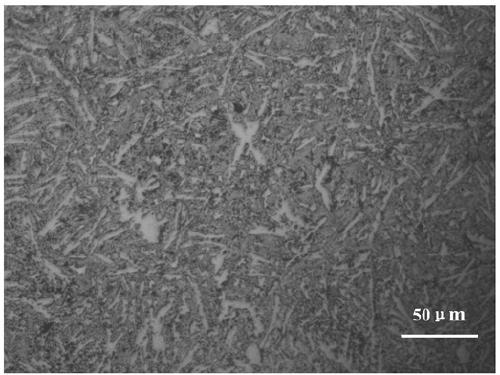

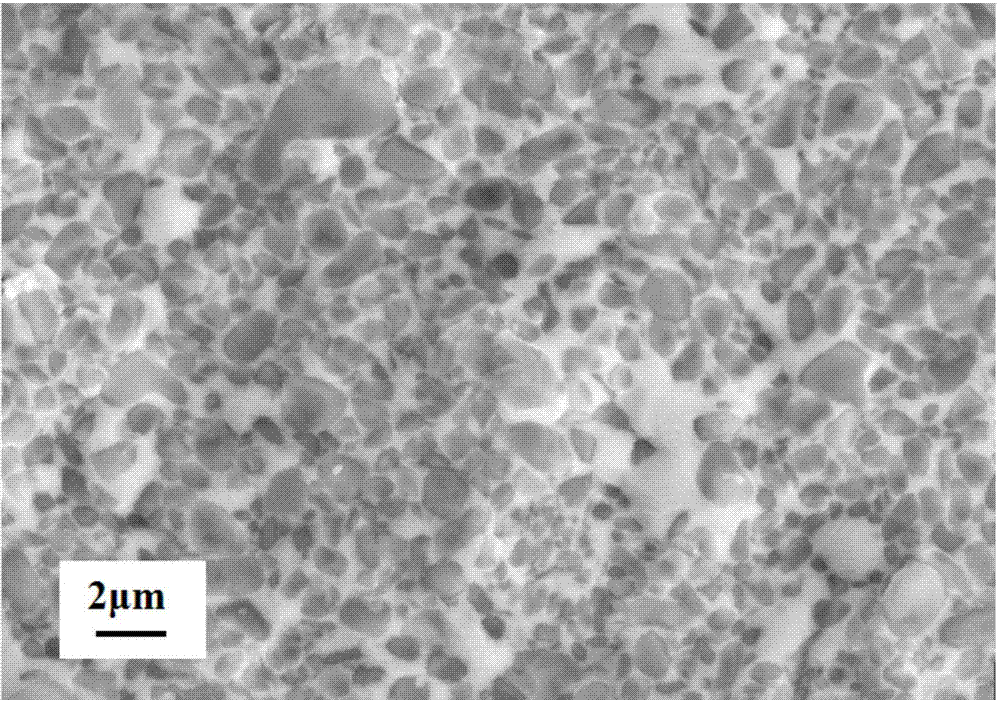

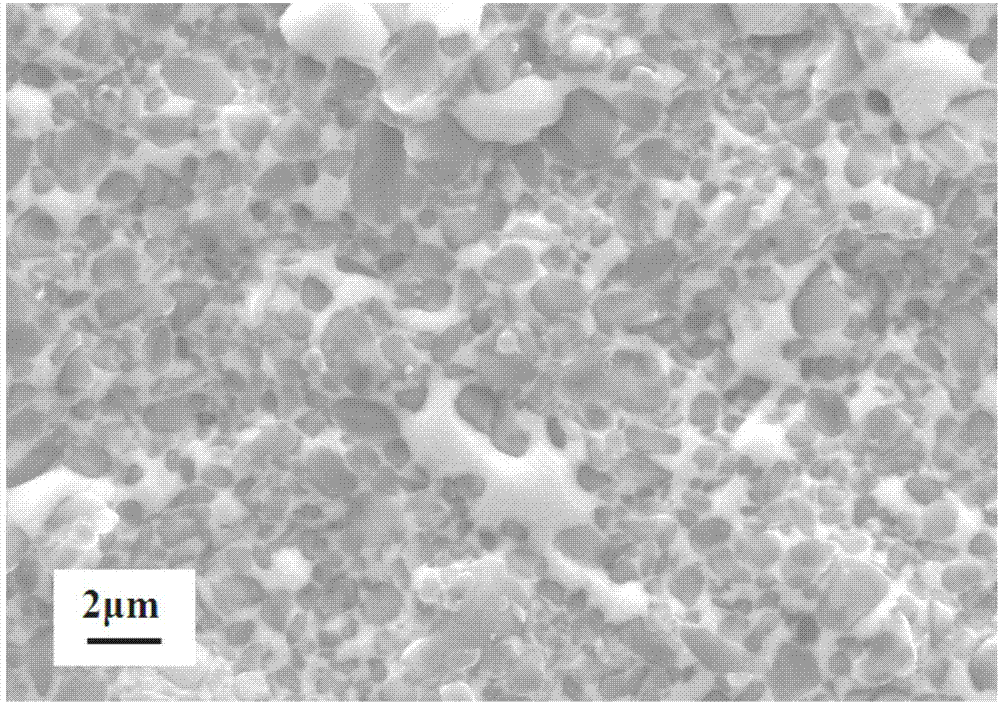

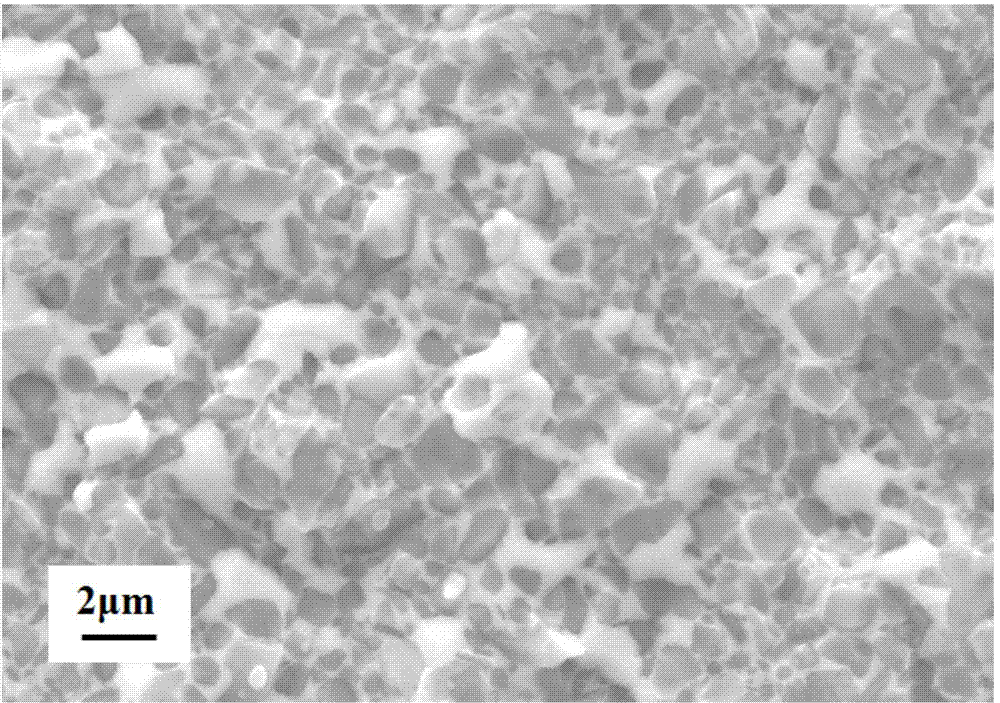

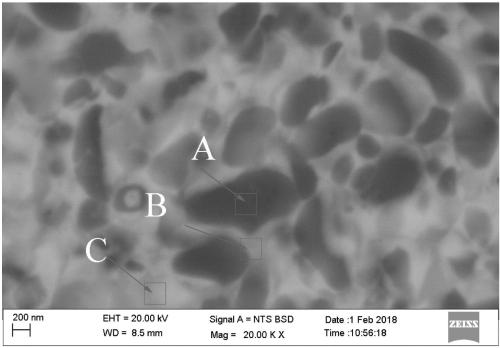

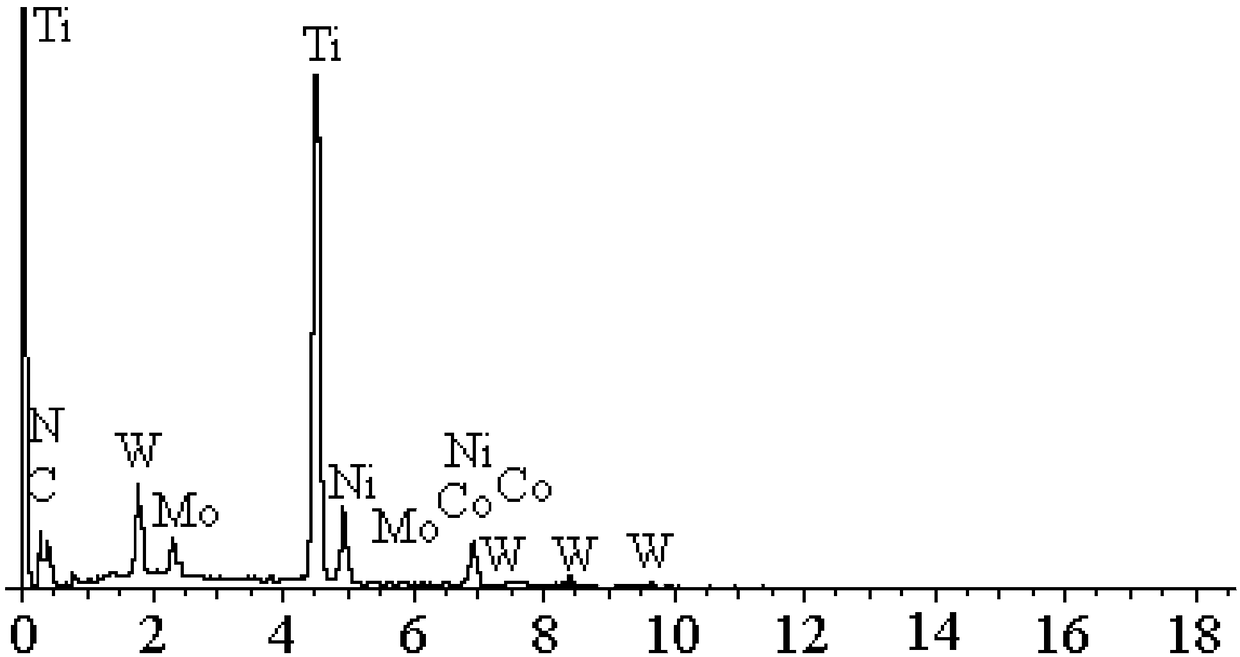

Method of fabricating ultra-fine cermet alloys with homogeous solid grain structure

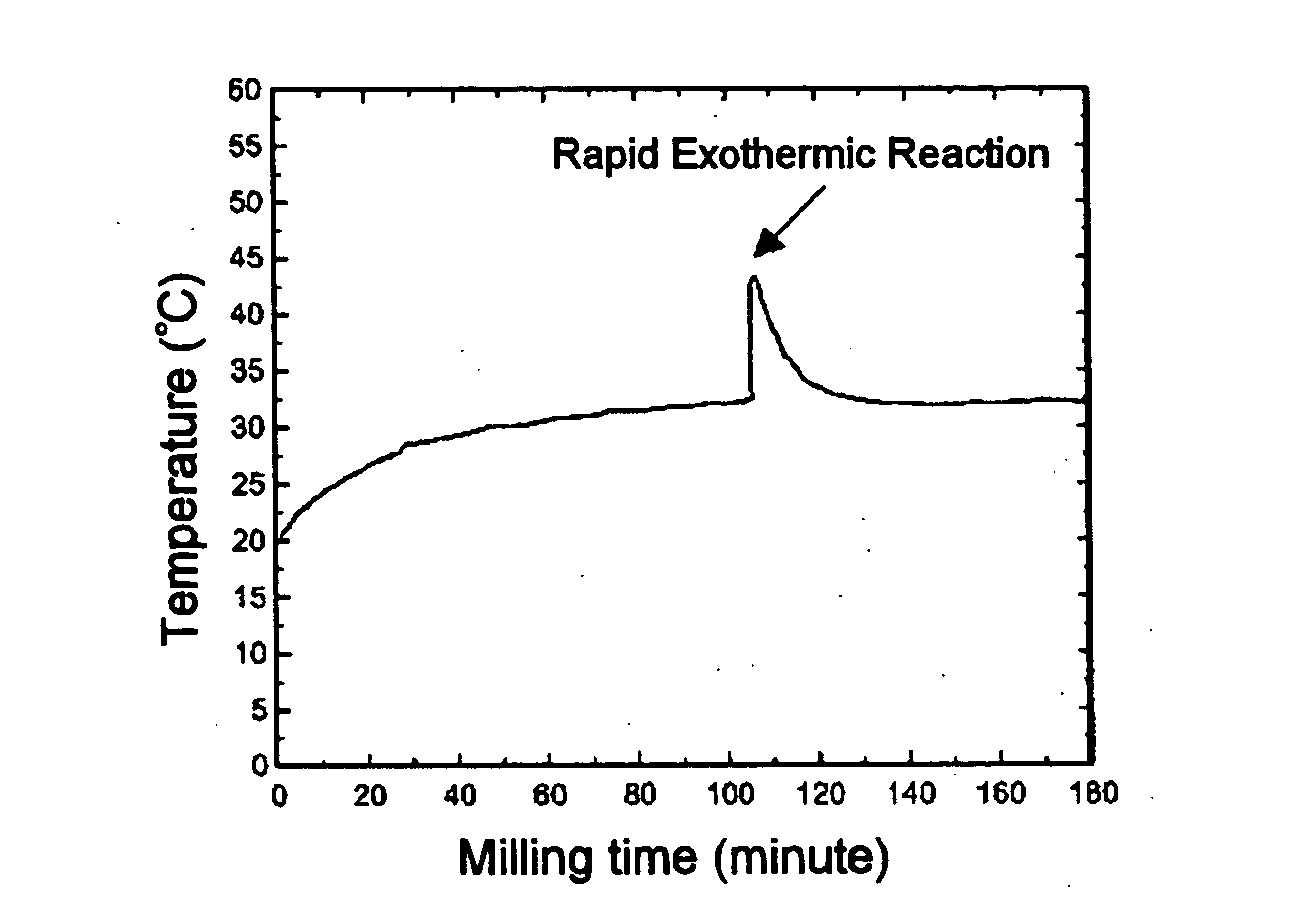

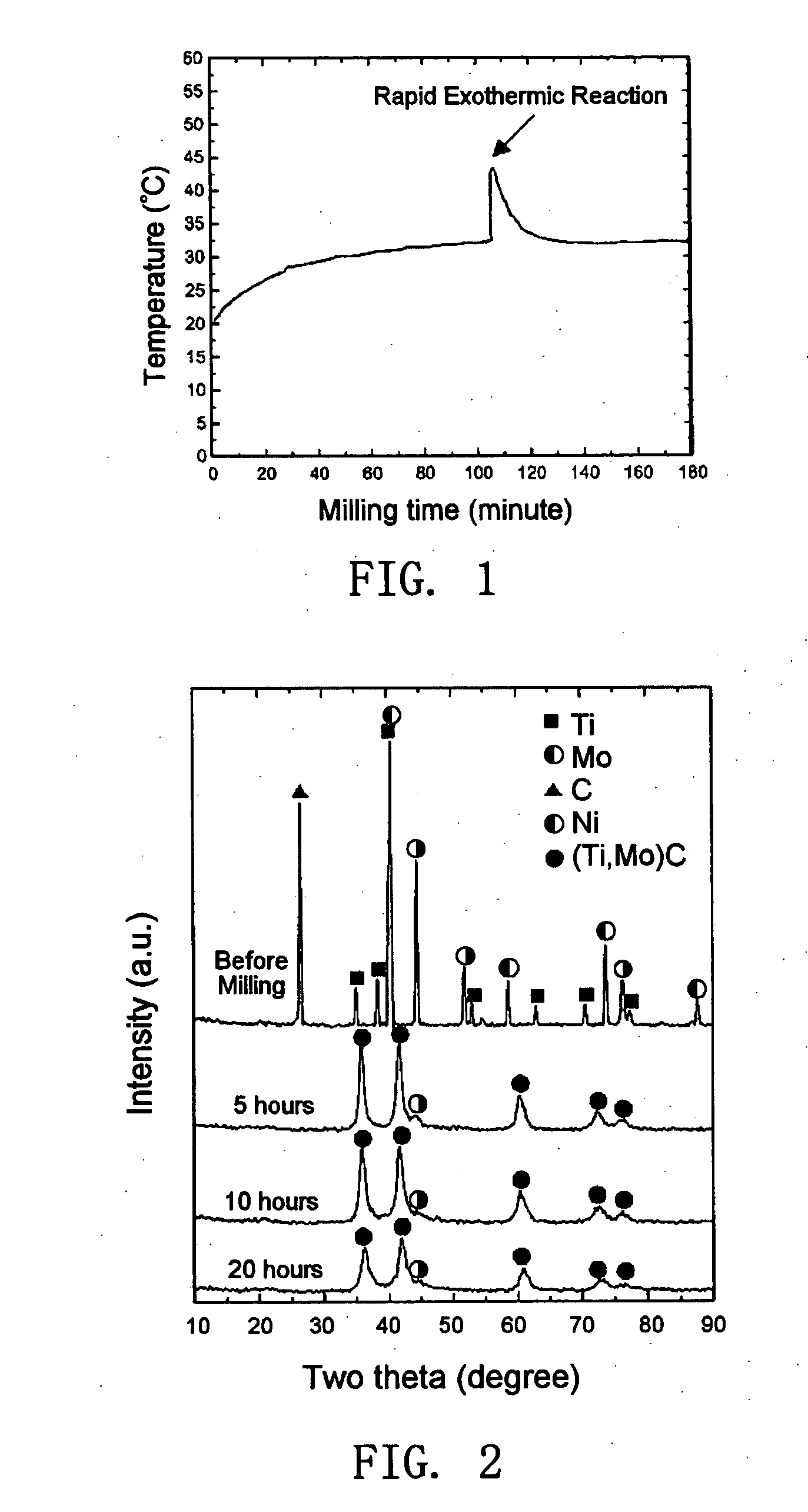

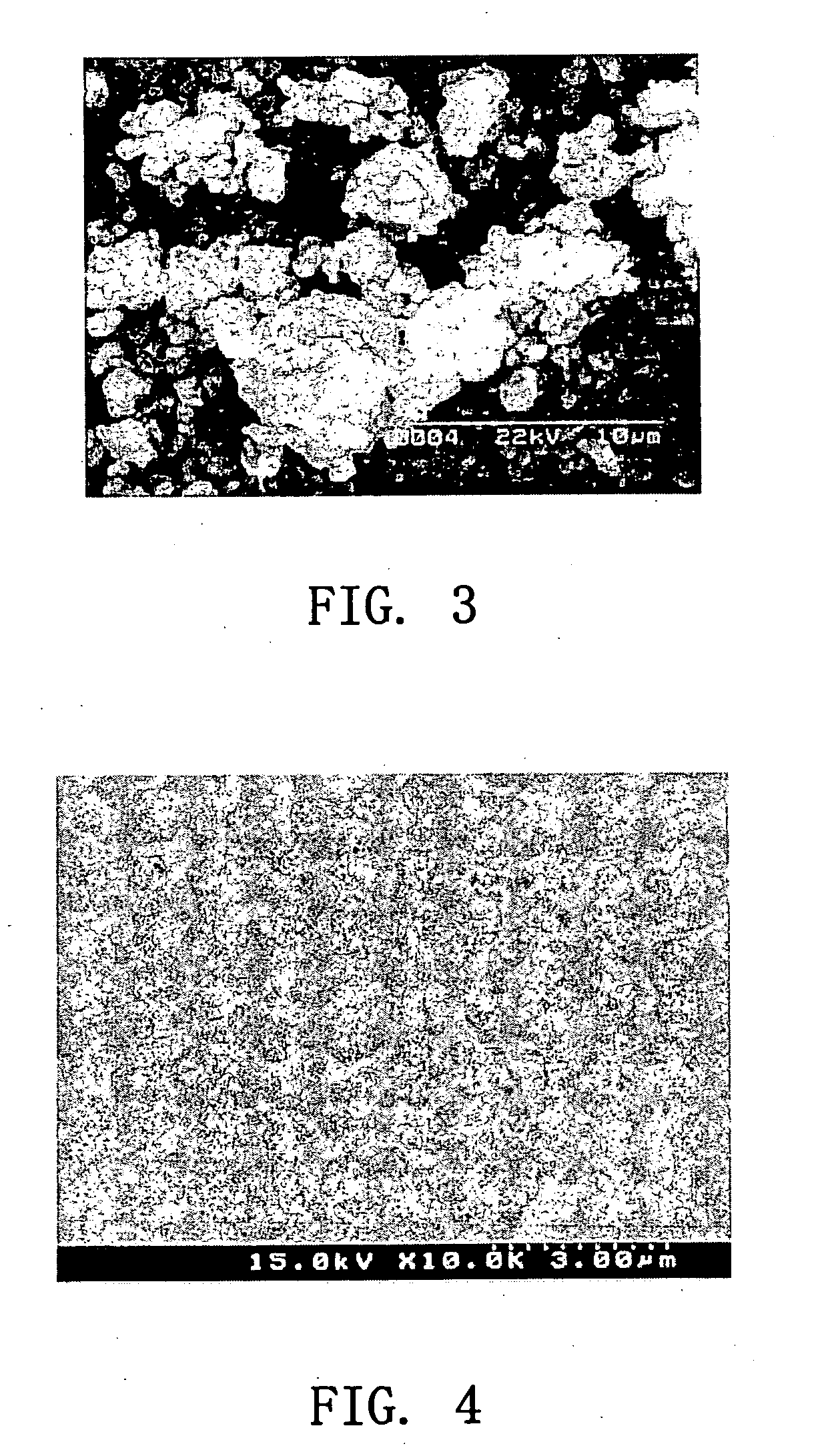

InactiveUS20050047950A1High hardnessUniform microstructureTransportation and packagingMetal-working apparatusChemical synthesisHigh energy

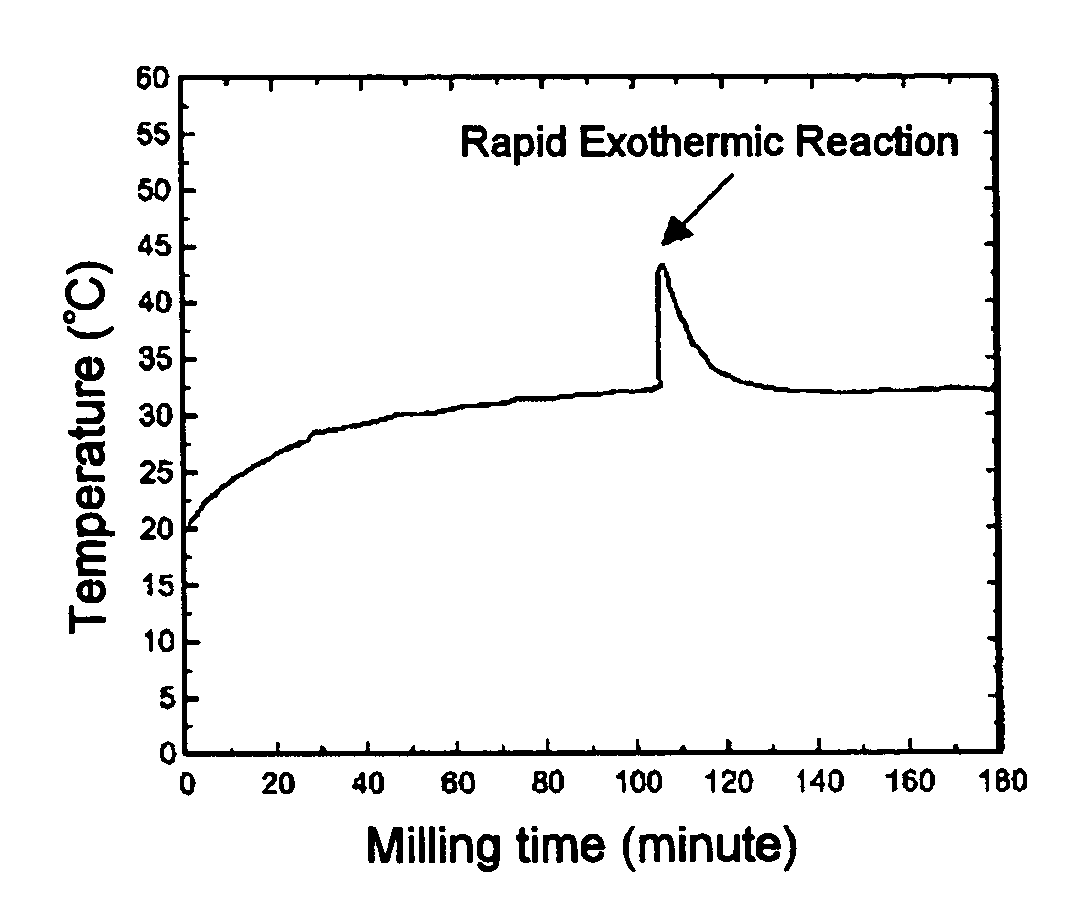

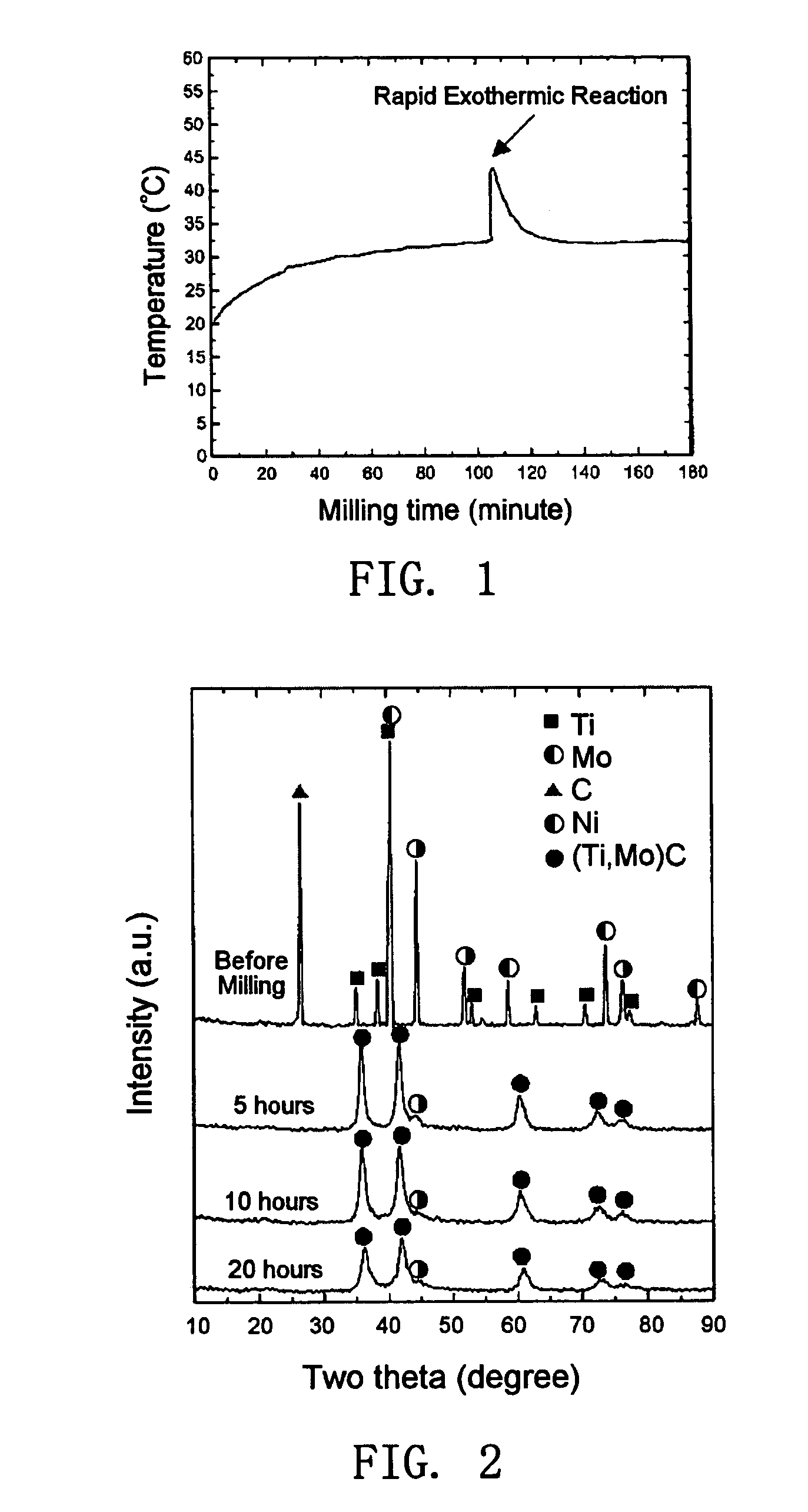

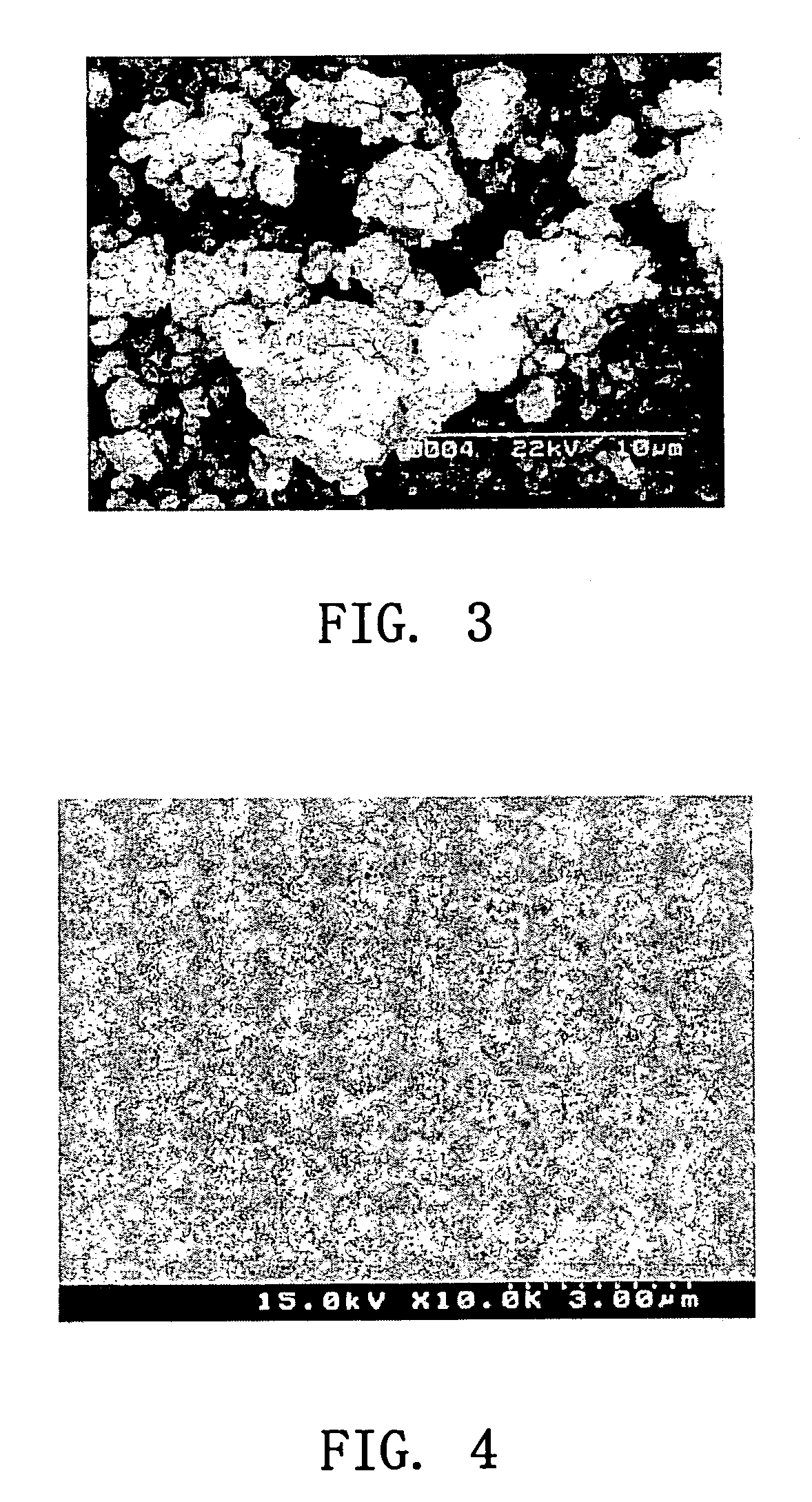

The present invention relates to a method of fabricating ultra-fine grain cermet alloys with a homogenous solid solution grain structure. More particularly, the invention relates to a method of fabricating an ultra-fine TiC-base cermet alloy with a homogenous solid solution structure which does not comprise a core-rim structure in the carbide grain. The object of the present invention is to provide a method of fabricating a TiC-base cermet alloy without the core-rim structure. The above objects of the present invention could be achieved by employing a conventional sintering process (vacuum sintering) of (Ti,TM)C carbide obtained from a mechano-chemical synthesis (high energy ball-milling) from milling the powders of Ti, TM, Ni and Co metals.

Owner:KOREA INST OF SCI & TECH

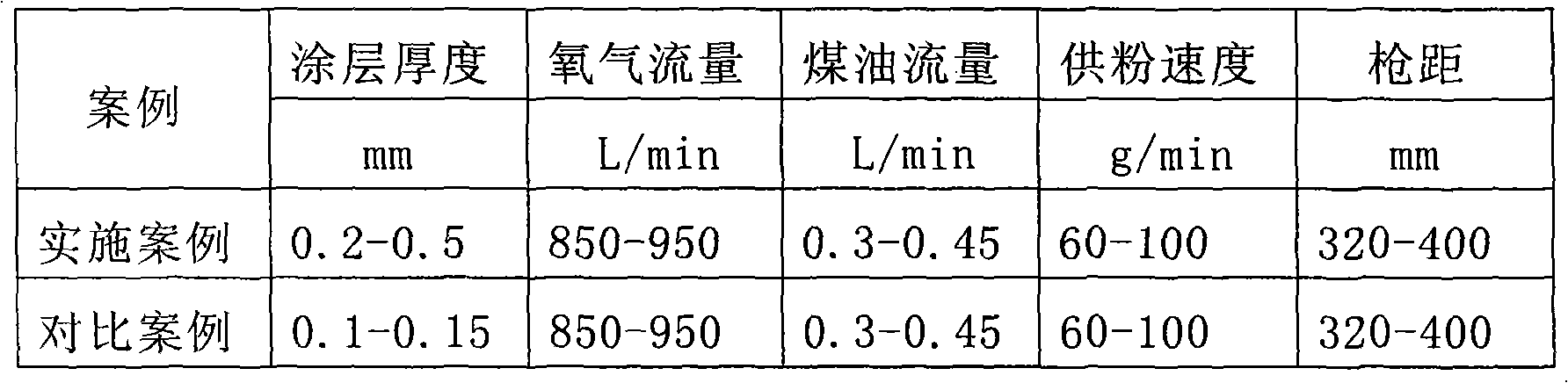

Spraying method of wear-resistant coating on roll surface of technology roller of cold rolling unit

InactiveCN101928910AFulfil requirementsHigh bonding strengthMolten spray coatingThermal sprayingWear resistant

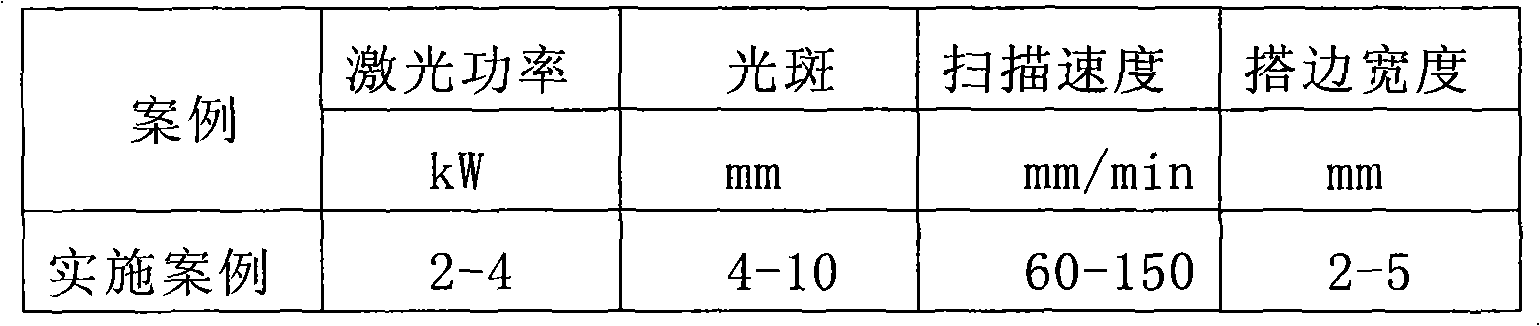

The invention discloses a spraying method of a wear-resistant coating on the roll surface of a technology roller of a cold rolling unit. A supersonic flame spraying device and a CO2 laser are used. The method comprises the following steps of: firstly, pretreating the substrate surface of a technology roller before hot spraying, and setting the working parameters of a spraying device; then, spraying a WC metal ceramic alloy powder material on the substrate surface of the technology roller, wherein the WC content in the powder material is 73-88%, the alloy mainly comprises NiCr or Co, the alloy content is 12-27%, the powder size is 10-65 mum, and the thickness of the obtained coating is 200-500 mum; and finally, setting the working parameters of the CO2 laser, treating the obtained coating by laser, and blowing in argon gas to the coating during treatment for protection. The coating has ultrahigh binding strength to the technology roller and excellent wear resisting property, and the requirements of the cold rolling technology for the technology roller of the cold rolling unit are satisfied.

Owner:SHANGHAI BAOSTEEL EQUIP MAINTENANCE CO LTD

Method of fabricating ultra-fine cermet alloys with homogeneous solid grain structure

The present invention relates to a method of fabricating ultra-fine grain cermet alloys with a homogenous solid solution grain structure. More particularly, the invention relates to a method of fabricating an ultra-fine TiC-base cermet alloy with a homogenous solid solution structure which does not comprise a core-rim structure in the carbide grain.The object of the present invention is to provide a method of fabricating a TiC-base cermet alloy without the core-rim structure.The above objects of the present invention could be achieved by employing a conventional sintering process (vacuum sintering) of (Ti,TM)C carbide obtained from a mechano-chemical synthesis (high energy ball-milling) from milling the powders of Ti, TM, Ni and Co metals.

Owner:KOREA INST OF SCI & TECH

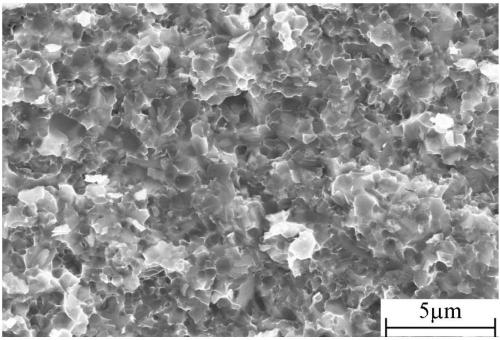

NbC-based lightweight metal cermet alloy with high wearing resistance and toughness and preparation method thereof

The invention relates to the technical field of preparation of metal cermet materials and relates to an NbC-based lightweight metal cermet alloy with high wearing resistance and toughness and a preparation method thereof. The metal cermet alloy comprises, by mass, 35-90% of NbC, 5-55% of (Nb, M) C, 5-30% of WC, 0-30% of TiC, 0-30% of TiN, 0-25% of Ti(C,N), 0-20% of Ni, 0-20% of Mo, 0-20% of Cr, 0-15% of Fe, 0-15% of Co, 0-20% of Mo2C, 0-15% of TaC, 0-2.5% of ZrC serving as a grain inhibitor, 0-5% of VC, 0-5% of Cr2C3, 0-1.2% of carbon black and other raw materials. The materials above are prepared into a mixture, the mixture is loaded into a stainless steel ball mill tank, absolute ethyl alcohol or hexane and other media, stearic acid and paraffin or PVA are added for ball milling, siftingand mold pressing to obtain a blank material, and the blank material is sintered and cooled to obtain the NbC-based lightweight metal cermet alloy with the high wearing resistance and toughness. TheNbC-based lightweight metal cermet alloy prepared by means of the method can overcome the defects that conventional WC hard alloys are low in high-temperature wearing resistance and large in specificgravity; moreover, the NbC-based lightweight metal cermet alloy is low in price, simple in process and suitable for industrial production.

Owner:ZIGONG CEMENTED CARBIDE CORP

Metal-ceramic alloy powder block for build-up welding

ActiveCN109112381AImprove craftsmanshipEasy to use and flexibleTransportation and packagingMetal-working apparatusBorideCrack resistance

The invention provides a ternary boride metal-ceramic Mo2FeB2 alloy powder block for build-up welding. The ternary boride metal-ceramic Mo2FeB2 alloy powder block is prepared from the following raw materials in parts by weight: 20-38 parts of iron boron, 32-50 parts of molybdenum powder, 7-24 parts of iron powder, 2-4 parts of nano-titanium carbide powder and 2-4 parts of yttrium oxide powder. When the iron boron, the molybdenum powder and the iron powder are used as raw materials for carrying out a metallurgical reaction so as to synthesize Mo2FeB2, an appropriate amount of the nano-titaniumcarbide powder is added; in a process of welding metallurgy, since the melting point of the nano-titanium carbide powder is as high as 3140 DEG C, the nano-titanium carbide powder can be used as a dispersed Mo2FeB2 non-spontaneous nucleation core in liquid metal, and the formed ternary boride Mo2FeB2 is enabled to be distributed in a dispersed way; therefore, the build-up welding metal has excellent high temperature hardness, wear resistance as well as good toughness and crack resistance. The steps are simple, the operation is convenient, and the practicality is high.

Owner:SHANDONG UNIV

Metal ceramic alloy preparation method and product thereof

The invention discloses a metal ceramic alloy preparation method and a product thereof. The metal ceramic alloy preparation method comprises the following four steps: burdening, mixing, compressing and sintering, wherein a sintering process comprises five stages of removing a molding agent at low temperature, raising the temperature and sintering in a solid phase atmosphere, raising the temperature and sintering at a liquid phase, sintering and keeping the temperature, and cooling rapidly, thereby obtaining metal ceramic alloy provided by the invention. The preparation method provided by the invention has the advantages of simpleness in operation, low production cost, easiness in controlling of the technological process, high production efficiency and the like. The surface of the metal ceramic alloy provided by the invention does not contain a metal bonded phase enrichment layer, thus facilitating the coating of the surface of the metal ceramic, and improvement of the bonding intensity of an alloy base body and the coating.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

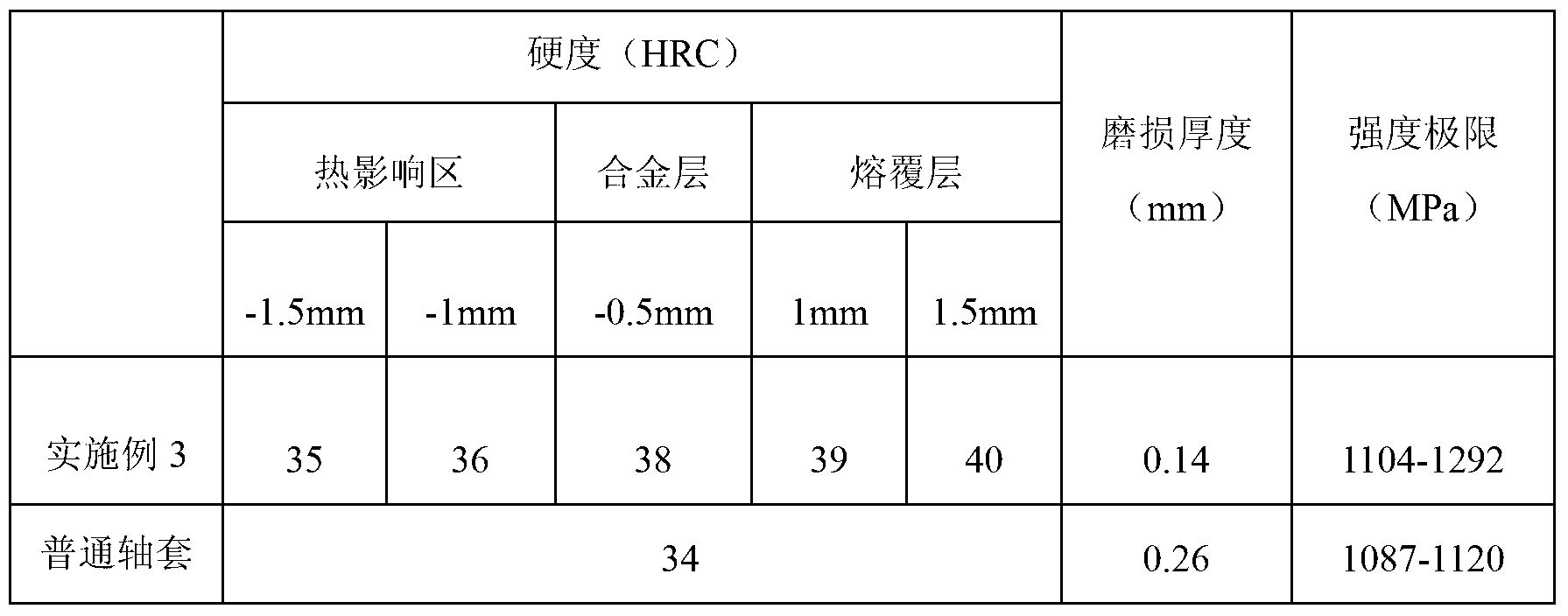

Special cobalt-based cermet alloy powder for laser cladding of surface of bushing

InactiveCN103305831AImprove wear resistanceHigh strengthMetallic material coating processesManganeseAlloy

The invention discloses special cobalt-based cermet alloy powder for the laser cladding of the surface of a bushing. The cobalt-based cermet alloy powder contains the following ingredients in percentage by weight: 11-13% of wolfram carbide, 0.2-0.3% of carbon, 5-8% of calcium fluoride, 3-5% of silicon nitride, 3-5% of boron, 3-5% of silicon, 5-8% of ferrum, 17-20% of molybdenum, 0.7-1% of manganese and the balance of cobalt. The cobalt-based cermet alloy powder is special for the laser cladding of the bushing and is used for improving the compactness of the metal structure of the surface of the bushing, so that the hardness, strength and wear resistance of the bushing are improved.

Owner:张家港和昊管理咨询有限公司

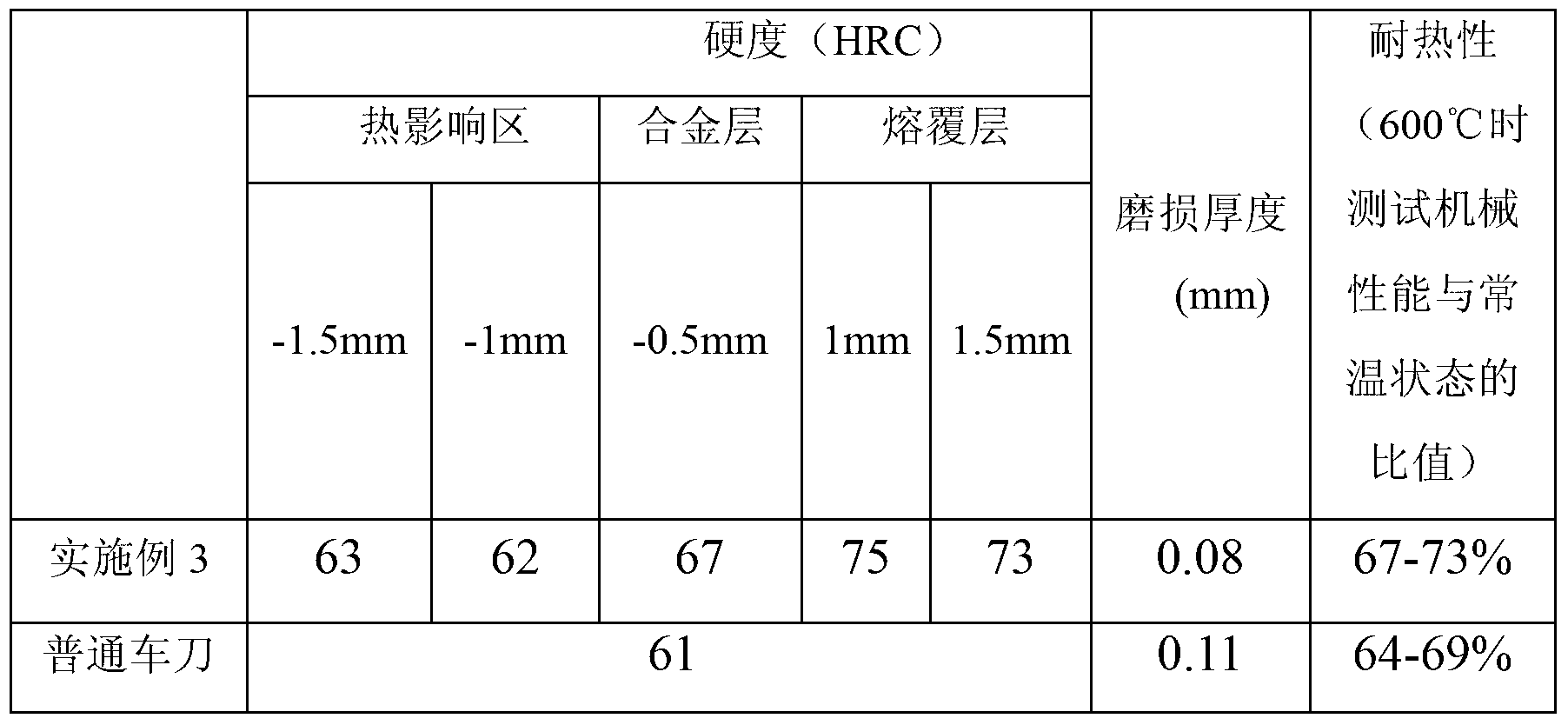

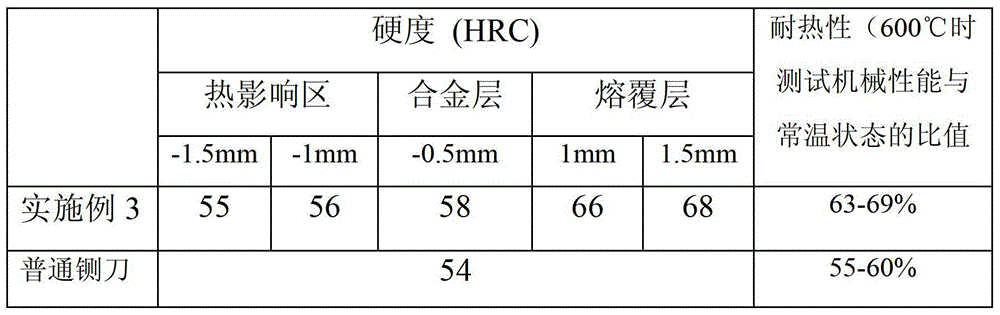

Cobalt-based metal ceramic alloy powder exclusively used in laser cladding of turning tool

InactiveCN103302286AHigh hardnessImprove wear resistanceMetallic material coating processesAlloyCobalt

The invention discloses cobalt-based metal ceramic alloy powder exclusively used in laser cladding of a turning tool. The cobalt-based metal ceramic alloy powder is composed of the following ingredients in percentage by weight: 11-14% of silicon carbide, 0.1-0.3% of carbon, 5-7% of calcium fluoride, 18-28% of chromium, 2-4% of boron, 0.2-0.4% of vanadium, 5-8% of iron, 4-6% of silicon, 13-16% of molybdenum, and the balance of cobalt. The cobalt-based metal ceramic alloy powder is exclusively used in laser cladding of the turning tool, improves the metal structure density of the turning tool, reduces the defects such as gas pores, cracks and shrinkage cavities of the cladding layer, and improves the wearing resistance, rigidity, heat resistance and strength of the turning tool, and meanwhile, the cost is reduced.

Owner:张家港和昊管理咨询有限公司

Method for preparing heat-resistant and abrasion-resistant composite guide carrier roller

ActiveCN101780642AImprove high temperature resistanceImprove wear resistanceOther manufacturing equipments/toolsAlloyCleansing Agents

The invention relates to a method for preparing a guide carrier roller used on a steel rolling production line, in particular to the method for preparing a heat-resistant and abrasion-resistant composite guide carrier roller. The method comprises the following steps of: firstly, preparing a guide carrier roller matrix, and carrying out conventional heat treatment on the guide carrier roller matrix; mixing Ni60 powder and Cr3C2 powder to prepare alloy powder; removing oil stains on the surface of the guide carrier roller matrix by using a cleaning agent; preheating the guide carrier roller matrix to be molten and coated; melting, coating and scanning the guide carrier roller matrix with a laser by adopting a method for pneumatically delivering powder; melting and coating the alloy powder on the surface of the guide carrier roller matrix for two times; and grinding the molten and coated guide carrier roller with a cylindrical grinder according to diameter dimensions to prepare the finished product composite guide carrier roller of which the surface is provided with a metal ceramic alloy abrasion-resistant layer. The method for preparing the composite guide carrier roller has high controllability of technological process, meets the requirements of continuous production on steel rolling lines under severe working conditions, saves a great number of precious heat-resistant stainless steel alloy materials and has the advantages of low price, high productivity and the like.

Owner:河北瑞兆激光再制造技术股份有限公司

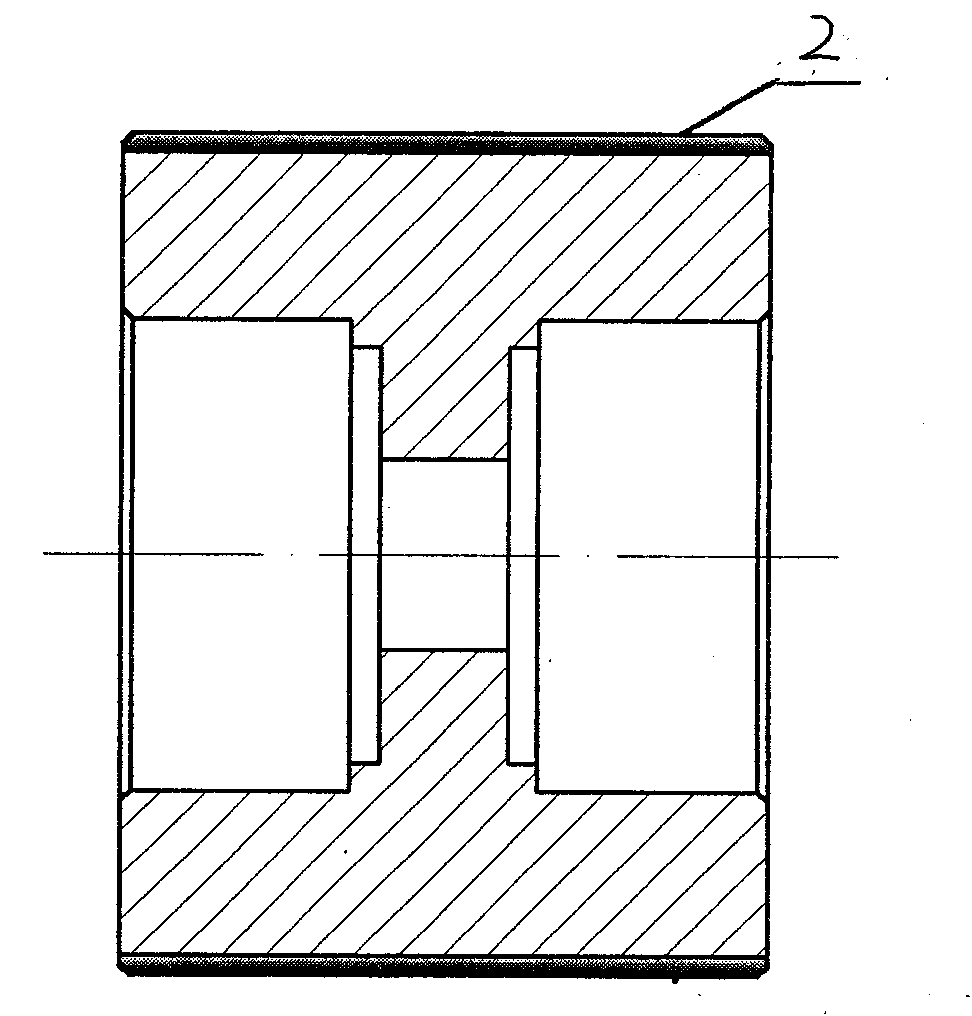

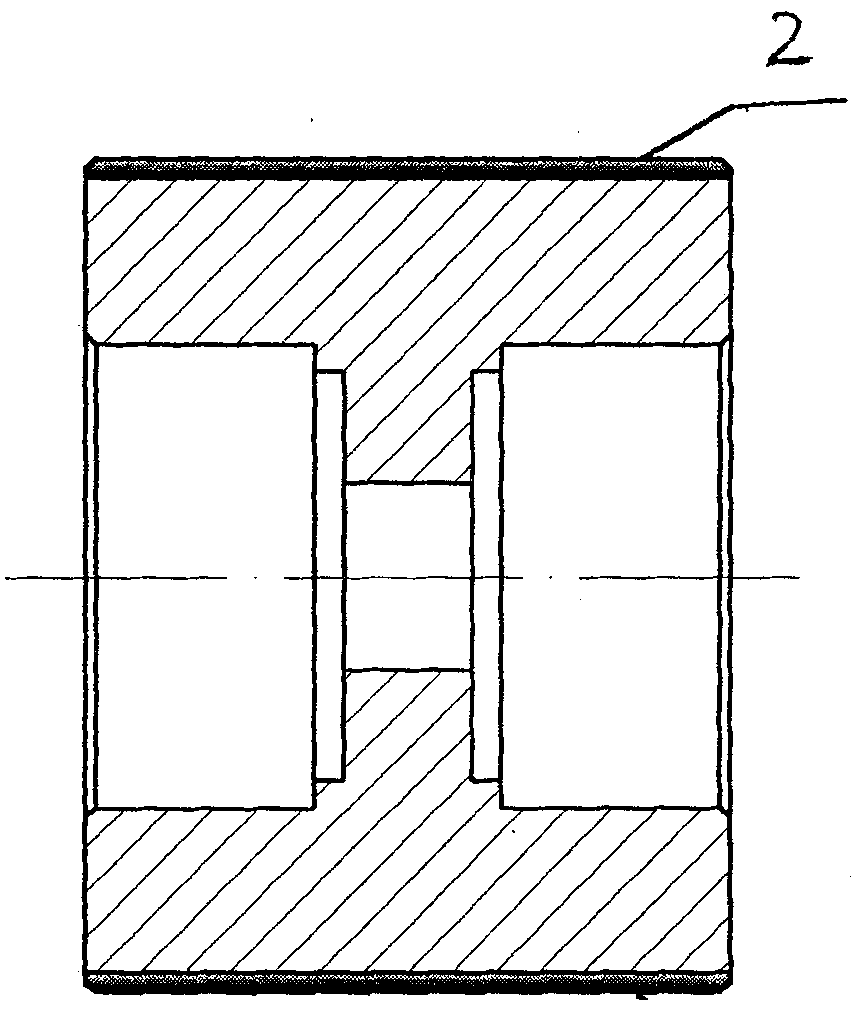

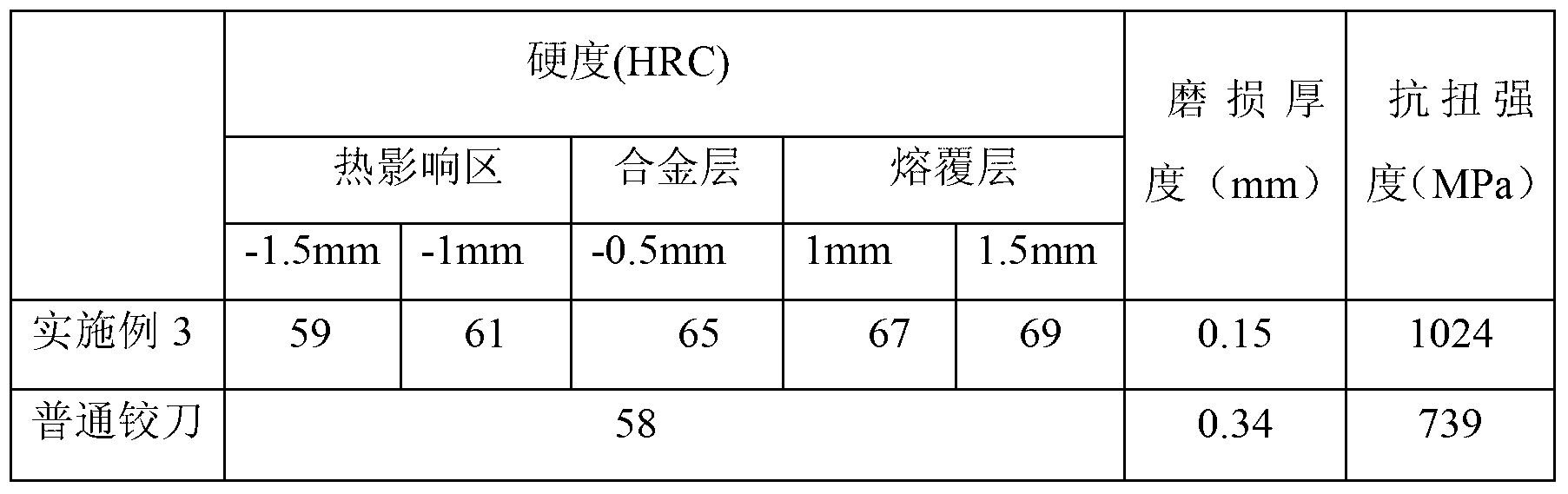

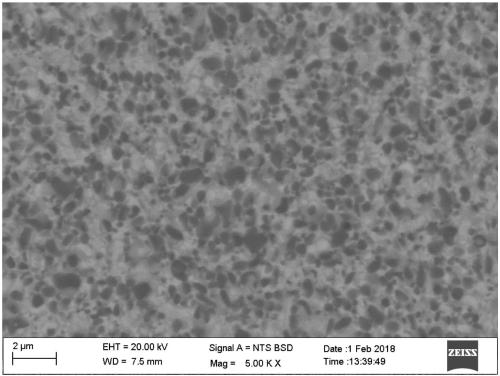

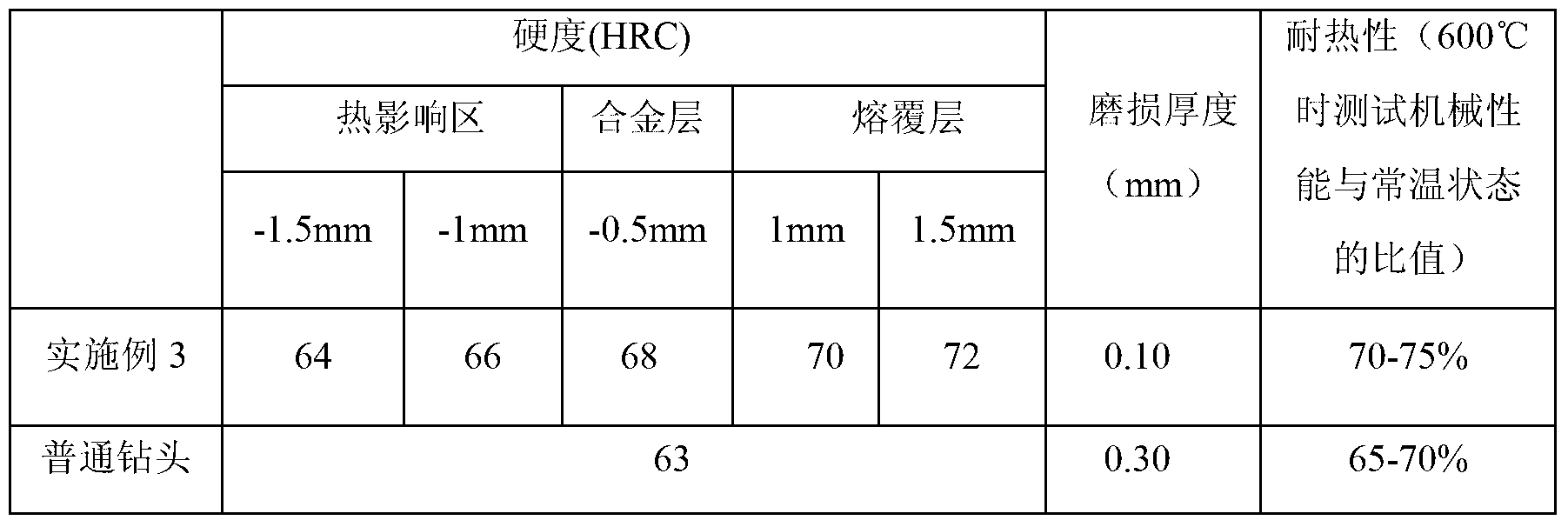

Special cobalt-based cermet alloy powder for laser cladding of surface of reamer

InactiveCN103305833AImprove wear resistanceHigh strengthMetallic material coating processesAdditive ingredientAlloy

The invention discloses special cobalt-based cermet alloy powder for the laser cladding of the surface of a reamer. The cobalt-based cermet alloy powder contains the following ingredients in percentage by weight: 12-14% of aluminum oxide, 0.2-0.3% of carbon, 1-3% of calcium fluoride, 3-5% of silicon nitride, 3-4% of boron, 0.2-0.6% of vanadium, 3-5% of silicon, 6-8% of ferrum, 18-20% of molybdenum and the balance of cobalt. The cobalt-based cermet alloy powder is special for the laser cladding of the reamer and is used for improving the compactness of the metal structure of the surface of the reamer, so that the hardness, strength and wear resistance of the reamer are improved.

Owner:张家港和昊管理咨询有限公司

Metal ceramic alloy free of core-ring structure and preparation method thereof

ActiveCN109338193ASmall expansion coefficientRealize microcrystallization interfacial bonding methodMaterials preparationAlloy

The invention relates to the technical field of metal ceramic material preparation, and relates to a metal ceramic alloy free of a core-ring structure and a preparation method thereof. The metal ceramic alloy free of the core-ring structure comprises the following components of, in percentage by weight, 10-55% of Ti (C, N) micron powder, 10-55% of (Ti, M) (C, N) micron powder, 10-55% of Ti (C, N)sub-micron or / and nano powder, 10-55% of (Ti, M) (C, N) sub-micron or / and nano powder, 5-20% of WC, 0-30% of TiC, 0-30% of TiN, 0-20% of Co, 0-20% of Ni, 0-10% of Cr, 0-15% of Mo2C, 0-10% of TaC / NbC,0-2. 5% of VC, 0-5% of Cr2C3, and 0-1.2% of carbon black; the components are prepared into a mixture according to a certain ratio, the mixture is subjected to ball milling, sieving and mould pressingto prepare a blank, and the blank is subjected to sintering and cooling to prepare a metal ceramic material free of the core-ring structure. According to the method, a powder metallurgy method is adopted to prepare the metal ceramic alloy free of the core-ring structure, and the technological difficulty of being not easy to control the thickness of a microcosmic core-ring structure in the preparation process a traditional metal ceramic with core-ring structures is solved.

Owner:ZIGONG CEMENTED CARBIDE CORP

Special nickel-based metal ceramic alloy powder for laser cladding on surface of piercing point

InactiveCN103305837AImprove toughnessImprove heat resistanceMetallic material coating processesAlloyNickel based

Owner:张家港和昊管理咨询有限公司

Metal ceramic alloy powder for plasma arc surfacing

ActiveCN108971799AShort molten pool lifetimeShort reaction processWelding/cutting media/materialsSoldering mediaBorideTitanium carbide

The invention provides metal ceramic alloy powder for plasma arc surfacing. The metal ceramic alloy powder is composed of the following raw materials of, by weight, 20-38 parts of Fe2B, 32-50 parts ofmolybdenum powder, 3-9 parts of iron powder, 2-4 parts of nanometer titanium carbide powder and 2-4 parts of yttrium oxide powder. According to the abrasion-resistant heat-resistant metal ceramic alloy powder for plasma arc surfacing, Mo2FeB2 ternary boride is used as main hard phases, and martensite is used as a matrix. By adding nanometer titanium carbide powder and yttrium oxide powder to theiron-based powder, the Mo2FeB2 ternary boride hard phases are dispersed, the surfacing impurity content is reduced, the technical requirements such as the high temperature oxidation resistance, high abrasion resistance and high cleanliness and anti-fatigue performance cleanliness are met, and the metal ceramic alloy powder is suitable for surfacing of hot working dies.

Owner:SHANDONG UNIV

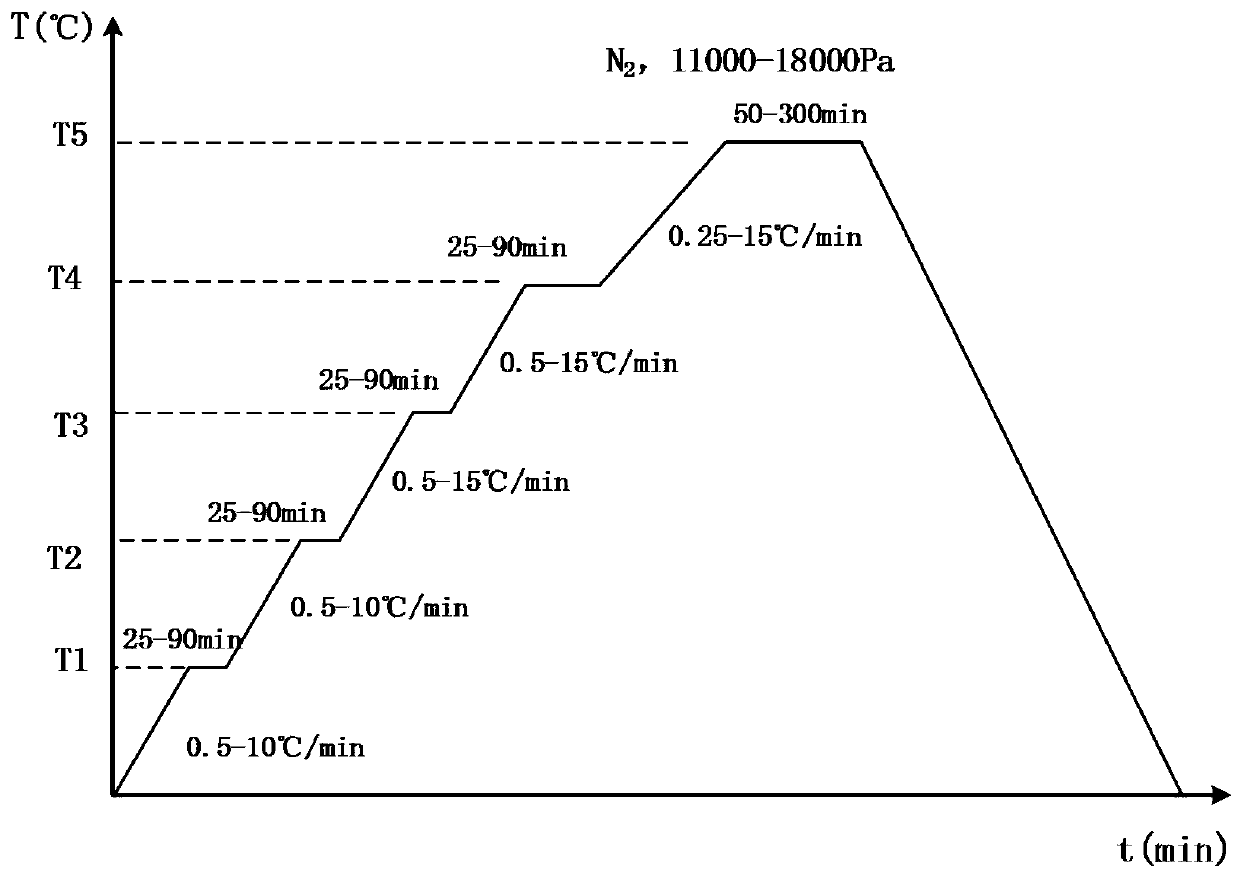

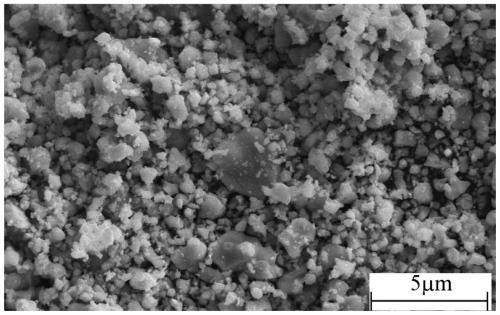

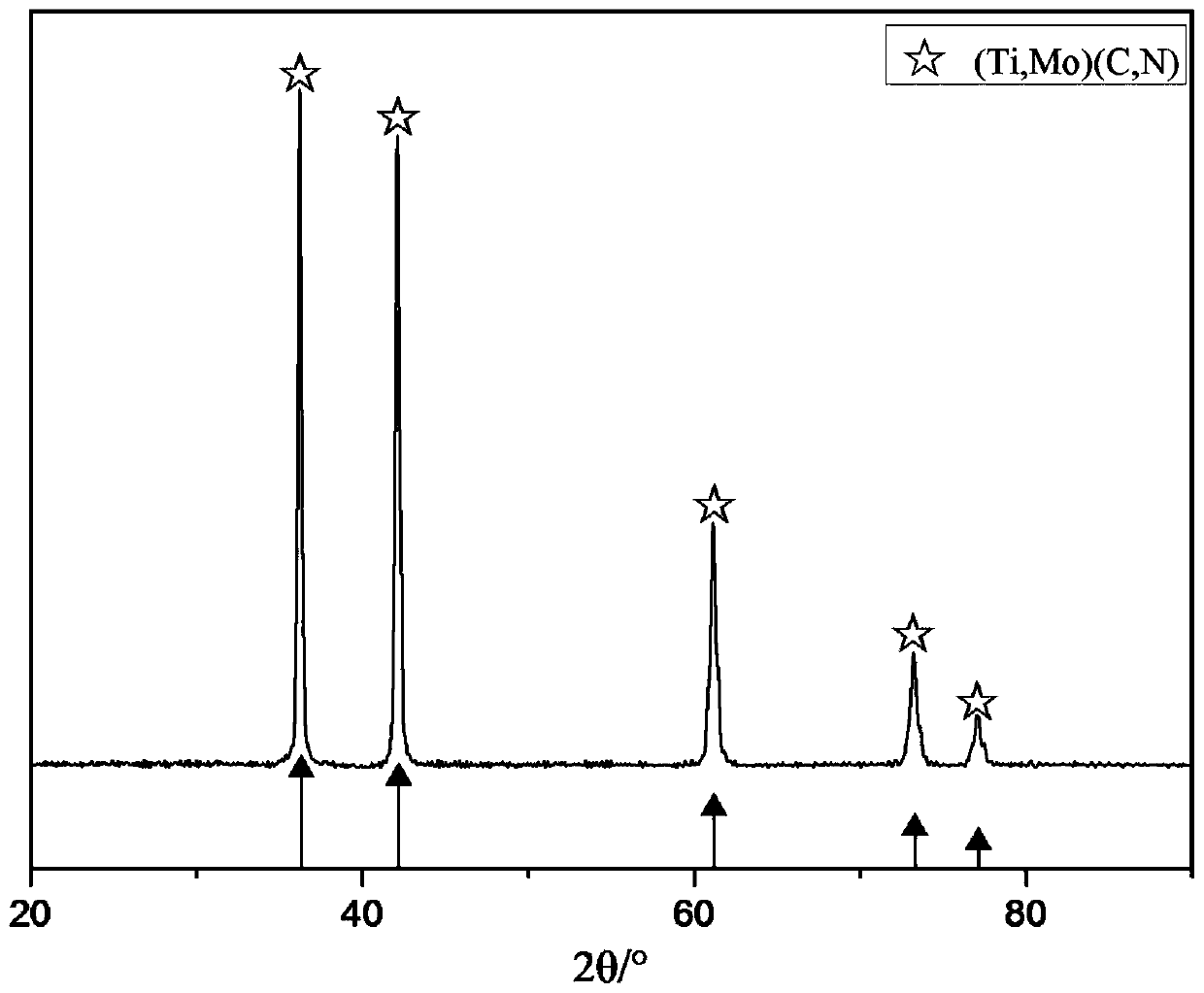

Solid solution alloy powder used for cermet and preparation method

ActiveCN110102752AImprove performanceLower sintering temperatureTransportation and packagingMetal-working apparatusSolid solutionMetal Ceramic Alloys

The invention relates to the technical field of materials of solid solution alloy powder used for cermet, in particular to the solid solution alloy powder used for the cermet and a preparation method.The main chemical formula of the solid solution alloy powder used for the cermet provided by the invention is (Ti, M) (C, N), wherein M is any one or consists of more than one of main active metal elements: W, Mo, Mn, Ta, Nb, Cr, V, Zr and Re; and the solid solution alloy powder comprises the following components: 10-50 % of main active metal M, 8.5-12.5 % of Ct, 8.5-12.5 % of N, not greater than0.35 % of Cf and the balance alloy element Ti. The preparation method provided by the invention overcomes the defects that high sintering temperature is needed in a sintering process when single-phase compound powder is added as a raw material traditionally and the bonding bone phase of cermet alloy is incomplete at the stage of forming a liquid-phase sintering solid solution; each active elementof the alloy is added as the solid solution in the raw material, so that the final cermet performance can be effectively reinforced; and the production technology is simple and easy to control, and is suitable for industrial production.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Laser cladding powder for preparing hard strengthened layer on surface of zinc pot roller shaft sleeve

PendingCN113373440AExtended service lifeHigh hardnessMetallic material coating processesAlloyMetal Ceramic Alloys

The invention relates to the field of laser cladding, in particular to a laser cladding powder material for preparing a hard strengthened layer on the surface of a zinc pot roller shaft sleeve, the powder material is mixed powder of iron-based powder and metal ceramic alloy powder, the iron-based powder accounts for 50-80% by mass, and the particle size of the iron-based powder is 10-80 microns; the metal ceramic alloy powder accounts for 20-50% by mass, and the particle size of the metal ceramic alloy powder is 10-80 microns; and the iron-based powder and the metal ceramic alloy powder are uniformly mixed. The iron-based powder comprises, by mass, 0.01%-0.2% of C, 15%-20% of Cr, 2%-6% of Cu, 0.1%-2% of Mn, 0.01%-0.5% of Nb, 2%-6% of Ni, 0.2%-1.5% of Si and the balance of Fe. The metal ceramic alloy powder comprises the following components in percentage by mass: 2-6% of C, 0-20% of Co and the balance of W. The powder material is suitable for laser cladding equipment including traditional laser cladding equipment and high-speed laser cladding equipment, and a high-hardness laser cladding layer can be prepared.

Owner:芜湖舍达科技有限公司

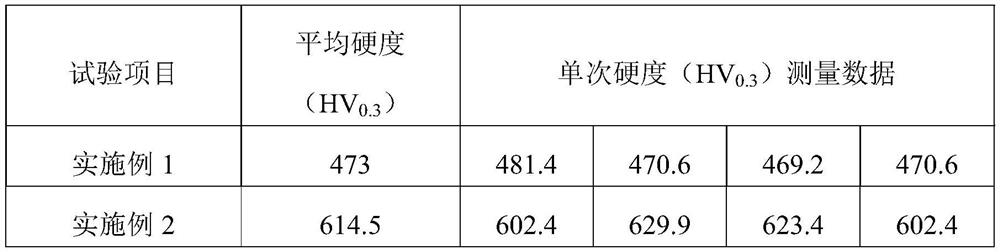

Cobalt-based metal ceramic alloy powder exclusively used in laser cladding of surface of drill bit

InactiveCN103302284AImprove wear resistanceImprove impact resistanceMetallic material coating processesAlloyCobalt

The invention discloses cobalt-based metal ceramic alloy powder exclusively used in laser cladding of the surface of a drill bit. The cobalt-based metal ceramic alloy powder is composed of the following ingredients in percentage by weight: 10-15% of tungsten carbide, 0.1-0.3% of carbon, 5-7% of calcium fluoride, 2-4% of silicon nitride, 3-5% of boron, 15-18% of chromium, 1-3% of silicon, 7-9% of iron, 18-22% of molybdenum, and the balance of cobalt. The cobalt-based metal ceramic alloy powder is exclusively used in laser cladding of the drill bit, improves the metal structure density of the drill bit, reduces the defects such as gas pores, cracks and shrinkage cavities of the cladding layer, and improves the wearing resistance, strength, rigidity, impact resistance and heat resistance of the drill bit.

Owner:张家港和昊管理咨询有限公司

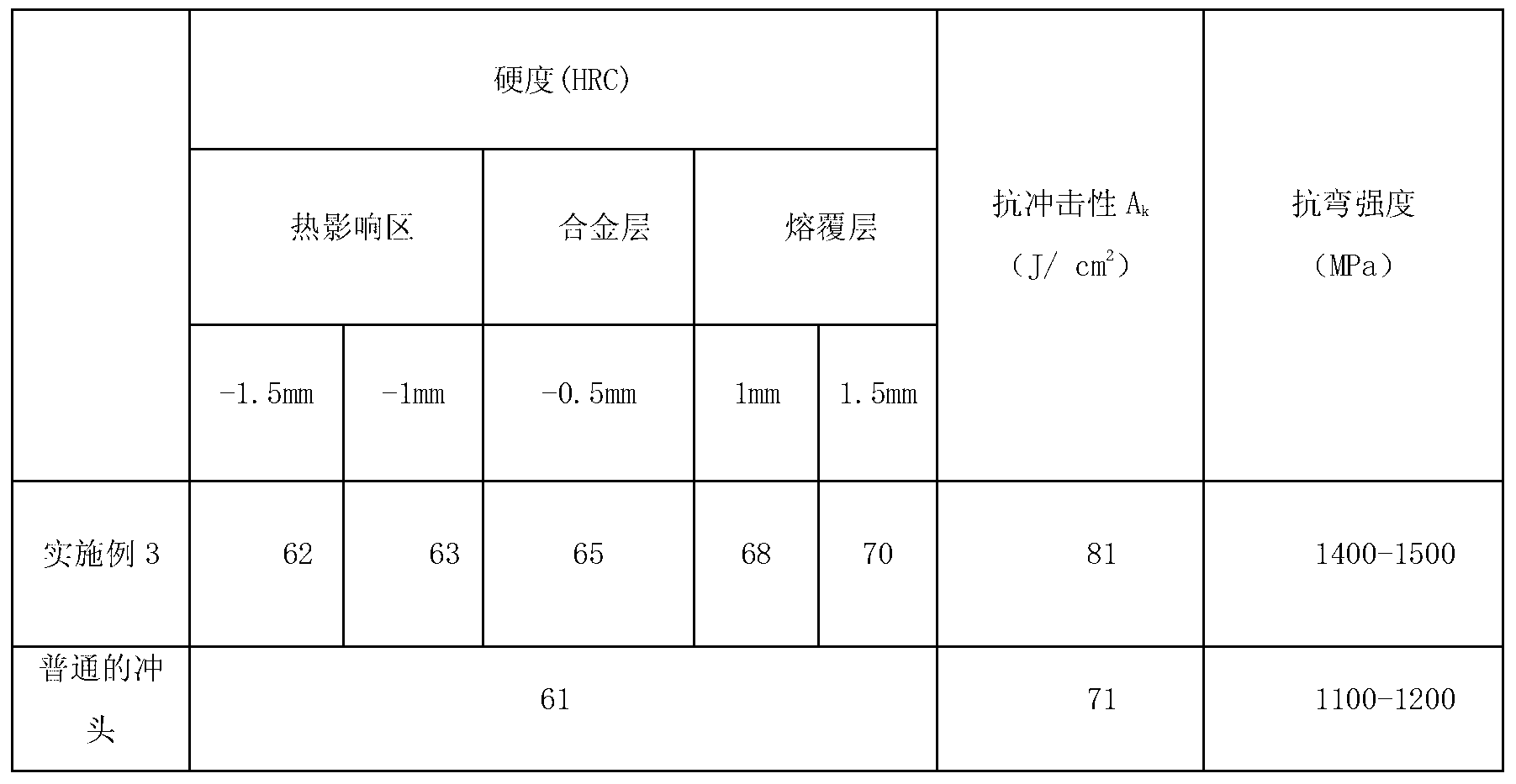

Nickel-based metal ceramic alloy powder exclusively used in laser cladding of surface of punch

ActiveCN103302285AImprove impact resistanceHigh strengthMetallic material coating processesAlloyMaterials science

The invention discloses nickel-based metal ceramic alloy powder exclusively used in laser cladding of the surface of a punch. The nickel-based metal ceramic alloy powder is composed of the following ingredients in percentage by weight: 13-15% of silicon carbide, 0.2-0.3% of carbon, 4-6% of calcium fluoride, 1-4% of silicon nitride, 1.5-1.8% of vanadium, 2-4% of silicon, 7-9% of iron, 17-18% of molybdenum, 15-17% of chromium, and the balance of nickel. The nickel-based metal ceramic alloy powder is exclusively used in laser cladding of the surface of the punch, improves the metal structure density of the surface of the punch, improves the tenacity, strength, rigidity and impact resistance of the punch, and meanwhile, ensure that the punch has sufficient toughness.

Owner:CHANGZHOU TIANZHENG IND DEV CO LTD

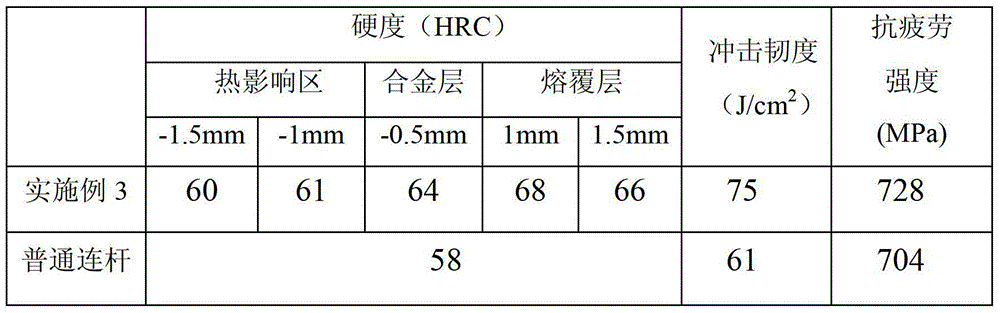

Special nickel-base metal ceramic alloy powder for connecting rod laser cladding

InactiveCN103334103AHigh hardnessEnsure toughness and strengthMetallic material coating processesManganeseAlloy

The invention discloses a special nickel-base metal ceramic alloy powder for connecting rod laser cladding, which comprises the following components in percentage by weight: 10-12% of titanium carbide, 0.8-1.4% of carbon, 2-4% of calcium fluoride, 2-4% of silicon nitride, 9-12% of germanium, 18-24% of chromium, 2-4% of silicon, 5-7% of iron, 5-8% of molybdenum, 0.1-0.4% of manganese and the balance of nickel. The nickel-base metal ceramic alloy powder is specially used for connecting rod laser cladding, and can form a cladding layer on the connecting rod surface by a laser cladding technique. The nickel-base metal ceramic alloy powder can reduce bubbles, cracks and shrinkage void defects on the cladding layer, and enhances the fatigue resistance, toughness and hardness of the connecting rod.

Owner:张家港和昊管理咨询有限公司

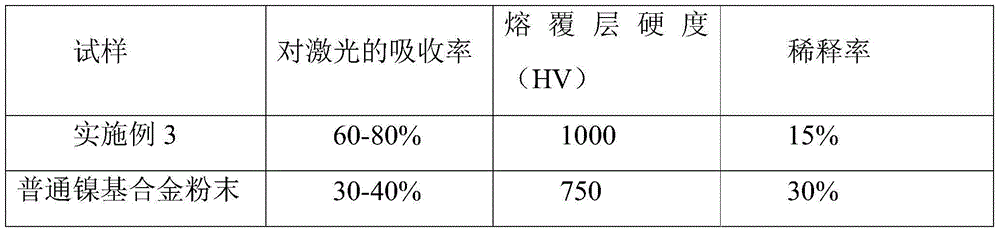

Cobalt-base metal alloy powder special for continuous fiber laser cladding

InactiveCN103600067AImprove absorption and utilizationHigh hardnessMetallic material coating processesCobaltBase metal alloy

The invention discloses cobalt-base metal alloy powder special for continuous fiber laser cladding. The cobalt-base metal alloy powder comprises, by weight, 11-14% of silicon carbide, 5-7% of calcium fluoride, 12-15% of molybdenum, 8-12% of chromium, 2-4% of silicon nitride, 4-6% of silicon, 0.1-0.2% of carbon, 2-4% of antimony and the balance cobalt. The cobalt-base metal alloy powder is specially applied to cladding processes of continuous fiber lasers, absorption and utilization rate of lasers is obviously increased, and formed cladding layers have high hardness, tenacity and corrosion resistance, are compact in organization and are formed without defects such as pores, cracks and contraction cavities; further, dilution rate can be effectively controlled, and the cobalt-base metal alloy powder is simple and convenient to process and free of pre-heat-treatment and post-heat treatment.

Owner:樊宇

Special cobalt-base metal ceramic alloy powder for guillotine laser cladding

The invention discloses a special cobalt-base metal ceramic alloy powder for guillotine laser cladding, which comprises the following components in percentage by weight: 11-13% of titanium carbide, 0.1-0.4% of carbon, 4-6% of calcium fluoride, 1-3% of silicon nitride, 6-9% of iron, 5-7% of chromium, 2-4% of zirconium, 1-3% of vanadium, 2-4% of silicon, 0.8-1.2% of manganese and the balance of Co. The cobalt-base metal ceramic alloy powder is specially used for guillotine laser cladding, reduces bubbles, cracks and shrinkage void defects on the cladding layer, and enhances the hardness, strength and shock resistance of the guillotine.

Owner:张家港和昊管理咨询有限公司

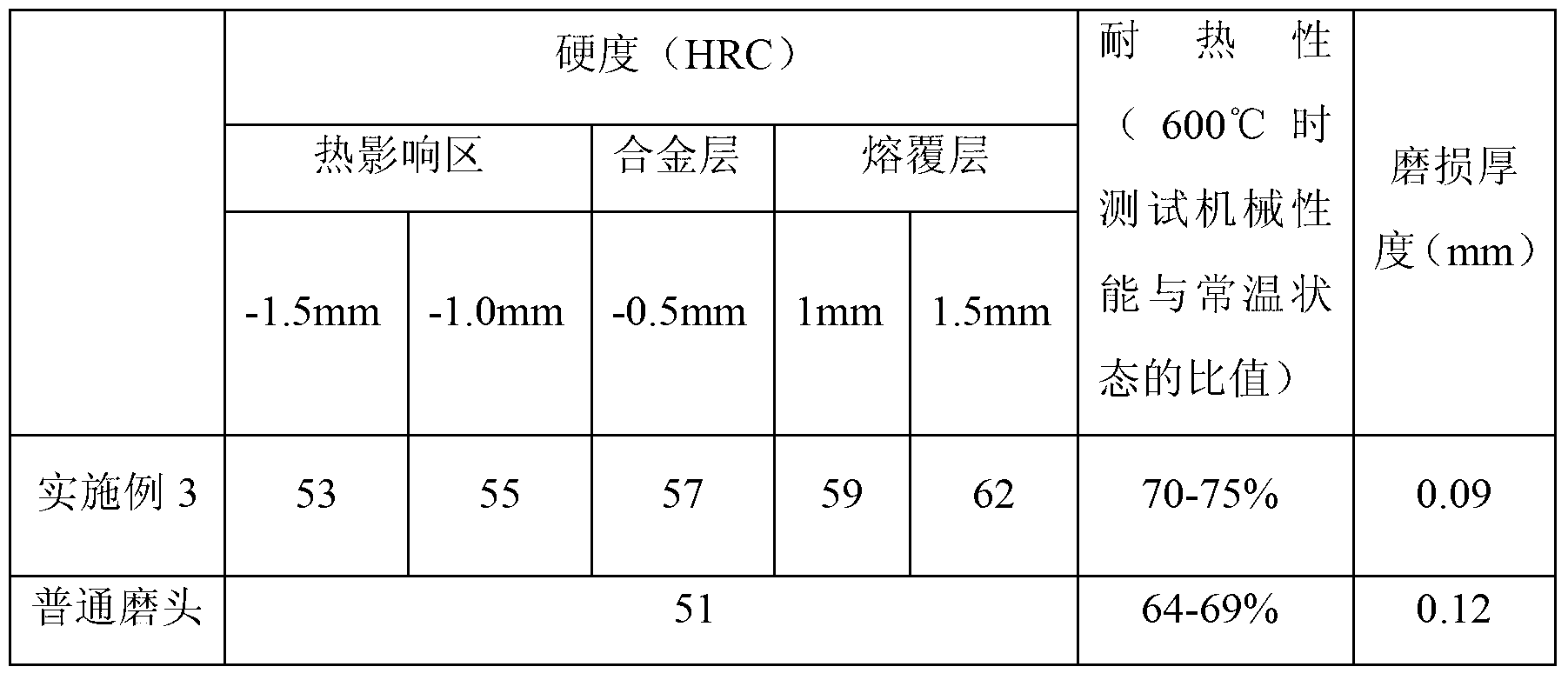

Special cobalt-based cermet alloy powder for laser cladding of grinding head

InactiveCN103305836AHigh hardnessImprove wear resistanceMetallic material coating processesManganeseAlloy

The invention discloses special cobalt-based cermet alloy powder for the laser cladding of a grinding head. The cobalt-based cermet alloy powder contains the following ingredients in percentage by weight: 13-15% of wolfram carbide, 0.2-0.4% of carbon, 2-4% of calcium fluoride, 2-4% of silicon nitride, 0.6-1% of silicon, 6-9% of ferrum, 9-12% of molybdenum, 1.2-1.6% of manganese, 17-20% of chromium and the balance of cobalt. The cobalt-based cermet alloy powder is special for the laser cladding of the grinding head and is used for improving the compactness of the metal structure of the grinding head and reducing the defects of pores, cracks and shrinkage voids of cladding, and the cost is reduced while the wear resistance, hardness, heat resistance and strength of the grinding head are improved.

Owner:张家港和昊管理咨询有限公司

Special metal ceramic alloy powder for continuous wave fiber laser cladding

InactiveCN103602979AImprove absorption and utilizationHigh hardnessMetallic material coating processesHigh energyAlloy

The invention discloses special metal ceramic alloy powder, matched with the characteristics of continuous fiber laser, for continuous wave fiber laser cladding. The metal ceramic alloy powder contains the following ingredients in percentage by weight: 11-13% of titanium carbide, 2-4% of lanthanum oxide, 5-8% of alumina, 2-4% of silicon nitride, 4-7% of silicon, 15-18% of molybdenum, 3-5% of boron, 0.1-0.2% of carbon and the balance of nickel and unavoidable impurities. The metal ceramic alloy powder is specially used for a cladding process of a high-energy continuous fiber laser, the absorption and utilization ratios of laser are improved obviously, and a formed cladding layer has high hardness, high toughness and high corrosion resistance; moreover, the tissue of the cladding layer is dense and is free from the defects of air holes, cracks, shrinkage cavities and the like; meanwhile, the dilution ratio can be controlled effectively, the process is simple and convenient, and heat treatment before / after cladding is not required.

Owner:浦晓峰

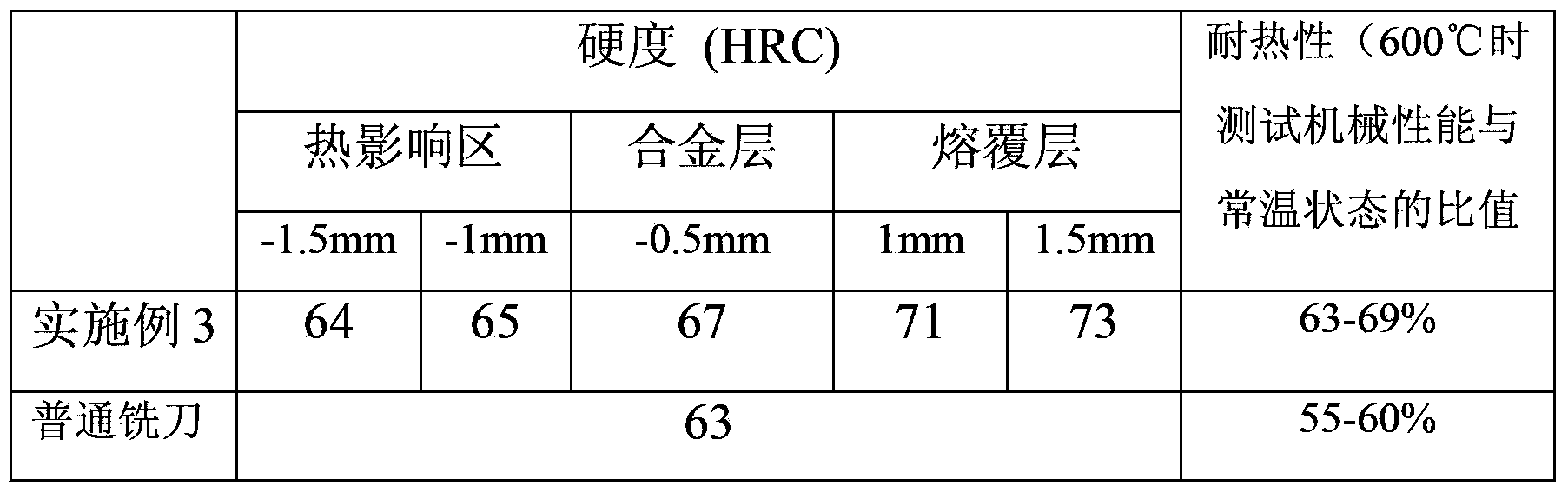

Cobalt-based metal ceramic alloy powder special for laser cladding of milling cutter

InactiveCN103537662AImprove refinementImprove tissue uniformityMetallic material coating processesMilling cutterAlloy

The invention discloses cobalt-based metal ceramic alloy powder special for laser cladding of a milling cutter. The powder comprises, by weight, 13-15% of tungsten carbide, 0.1-0.4% of carbon, 2-6% of calcium fluoride, 4-6% of silicon nitride, 4-6% of boron, 1.3-1.6% of vanadium, 1.1-1.4% of silicon, 6-8% of Fe, 11-14% of molybdenum, and the balance cobalt. The cobalt-based metal ceramic alloy powder is specially used for laser cladding of the milling cutter, and capable of improving the compactness of the metal structure of the milling cutter, reducing the defects of air holes, cracks and shrinkage cavities of a cladding layer, improving the wear resistance, rigidity heat resistance and strength of the milling cutter, and reducing cost.

Owner:张家港和昊管理咨询有限公司

Special cobalt-based metal ceramic powdered alloy for cladding process of continuous wave optical fiber laser

InactiveCN103614720AImprove absorption and utilizationHigh hardnessMetallic material coating processesIridiumHigh energy

The invention discloses special cobalt-based metal ceramic powdered alloy for cladding process of a continuous wave optical fiber laser. The special cobalt-based metal ceramic powdered alloy comprises 11-13% of silicon carbide, 5-7% of calcium fluoride, 2-4% of silicon nitride, 8-10% of chromium, 2-4% of iridium, 0.1-0.2% of carbon, 1-1.4% of manganese, 5-7% of iron and the balance of cobalt and inevitable impurities in percentage by weight. The cobalt-based metal ceramic powdered alloy is specially used for the cladding process of the high-energy continuous wave optical fiber laser; due to the adoption of the metal ceramic powdered alloy, the rate of absorption and utilization of laser is obviously improved; a cladding layer formed by the cobalt-based metal ceramic powdered alloy has high hardness, high toughness, high corrosion resistance and compact texture without defects such as air holes, cracks and shrinkage cavities; the process is simple and convenient, and the heat treatment before and after cladding is not needed.

Owner:范贺良

Special nickel base metal ceramic alloy powder for continuous wave fiber laser cladding

ActiveCN103602948AIncrease profitImprove absorption rateVacuum evaporation coatingSputtering coatingAlloyAbsorption rate

The invention discloses a special nickel base metal ceramic alloy powder for continuous wave fiber laser cladding. The special nickel base metal ceramic alloy powder contains the following components in percentage by weight: 15-21% of aluminum oxide, 9-13% of titanium dioxide, 2-5% of calcium fluoride, 2-6% of cerium oxide, 2-5% of silicon nitride, 2-4% of silicon and the balance of nickel bases. The nickel base metal ceramic alloy powder not only can be used for greatly increasing the absorption rate of a metal piece to laser and reducing the melting point, but also can be used for forming a cladding layer which is compact in internal tissue and free of defects such as cracks, shrinkage holes, air bubbles and the like on the surface in a continuous wave fiber laser cladding process, so that the service life of the metal piece is greatly prolonged, and the production cost is reduced.

Owner:CHANGZHOU TIANZHENG IND DEV CO LTD

A preparation method of laser cladding strengthened splitter cone

InactiveCN103436879BSimple processNo pollution in the processMetallic material coating processesNumerical controlChemical composition

The invention relates to a preparation method of a laser-cladding reinforced shunt taper, which mainly comprises the steps that after a common medium-low carbon alloy structural steel bar is machined according to a shunt taper drawing, a part contacted with molten aluminum is reduced by 0.5mm according to the size, and then continuously machined; metal ceramic alloy powder is prepared, wherein the metal ceramic alloy powder comprises the following chemical components by mass percent: 0.1-0.35% of C, 0.6-1.2% of Al, 0.7-0.9% of Si, 25-29% of Cr, 55-62% of Co, 2.1-2.8% of Yb, 4.3-4.9% of W, and the balance of Fe; the power is conveyed on the shunt taper by adopting a pneumatic or gravitational mode; high-energy light beams of a high-power semiconductor laser device are used for scanning, so that the alloy powder conveyed in place and metal on the surface of a substrate of the shunt taper have a quick metallurgical reaction; stress relief annealing is conducted on the laser-cladding shunt taper for 2-4h at 300-500 DEG C; slow furnace cooling is conducted; and finish machining of an alloy reinforcing layer is accomplished by a numerical control machine tool. The method is simple in preparation technology and pollution-free, and the prepared reinforced shunt taper is long in service life and low in cost.

Owner:YANSHAN UNIV

Cobalt-based metallic ceramic alloy powder special for continuous wave fiber laser cladding

ActiveCN103611927AIncrease profitImprove absorption rateMetallic material coating processesAlloyCobalt

The invention discloses a cobalt-based metallic ceramic alloy powder special for continuous wave fiber laser cladding. The cobalt-based metallic ceramic alloy powder comprises, by weight, 15-18% of aluminum oxide, 11-13% of titanium dioxide, 4-8% of calcium fluoride, 2-5% of cerium oxide, 2-4% of silicon nitride, 1-4% of antimony, 4-7% of boron and the balance cobalt base. By the cobalt-based metallic ceramic alloy powder, in the process of continuous wave fiber laser cladding, absorptivity of a metal piece for laser can be increased greatly, melting point is lowered, and a cladding layer which is compact in internal organizational structure and free of defects such as cracks, shrinkage cavities and bubbles can be formed on the surface of the metal piece, so that service life of the metal piece is prolonged greatly, and production cost is lowered.

Owner:CHANGZHOU TIANZHENG IND DEV CO LTD

Molybdenum iron boron ternary metal-ceramic alloy vacuum sintered friction welding boring bit

InactiveCN102039415AImprove performanceReduce weightDrill bitsBlast furnace componentsCermetSteel company

The invention relates to a molybdenum iron boron ternary alloy metal-ceramic boring bit. According to the molybdenum iron boron ternary alloy metal-ceramic boring bit, molybdenum, iron, boron and other nonmetallic substances are matched on an iron-based matrix in a certain ratio, and a ternary alloy metal-ceramic iron-based matrix with good toughness and abrasion resistance is obtained by superfine treatment and vacuum sintering; and the ternary alloy metal-ceramic iron-based matrix and the molded alloy structure steel form a boring bit for a blast furnace tapping machine or a spherical sheet tooth boring bit for mines by friction welding, namely forming a novel boring tool. The molybdenum iron boron ternary alloy metal-ceramic boring tool is the novel boring tool researched by Hubei Jiayu Pipe Industry Co., Ltd. and Wuhan University of Technology together, and is widely applied to blast furnace tapping holes of steel companies and rock advancement of mines. The boring bit has light weight, low price and high cost performance, and saves a large amount of precious tungsten metal resources.

Owner:湖北嘉裕钎具股份有限公司 +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com