Solid solution alloy powder used for cermet and preparation method

A solid solution alloy and cermet technology, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as reducing sintering temperature, and achieve the effect of improving alloy performance, saving sintering time, and controllable ball milling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

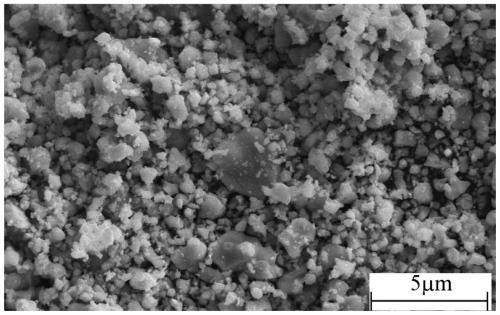

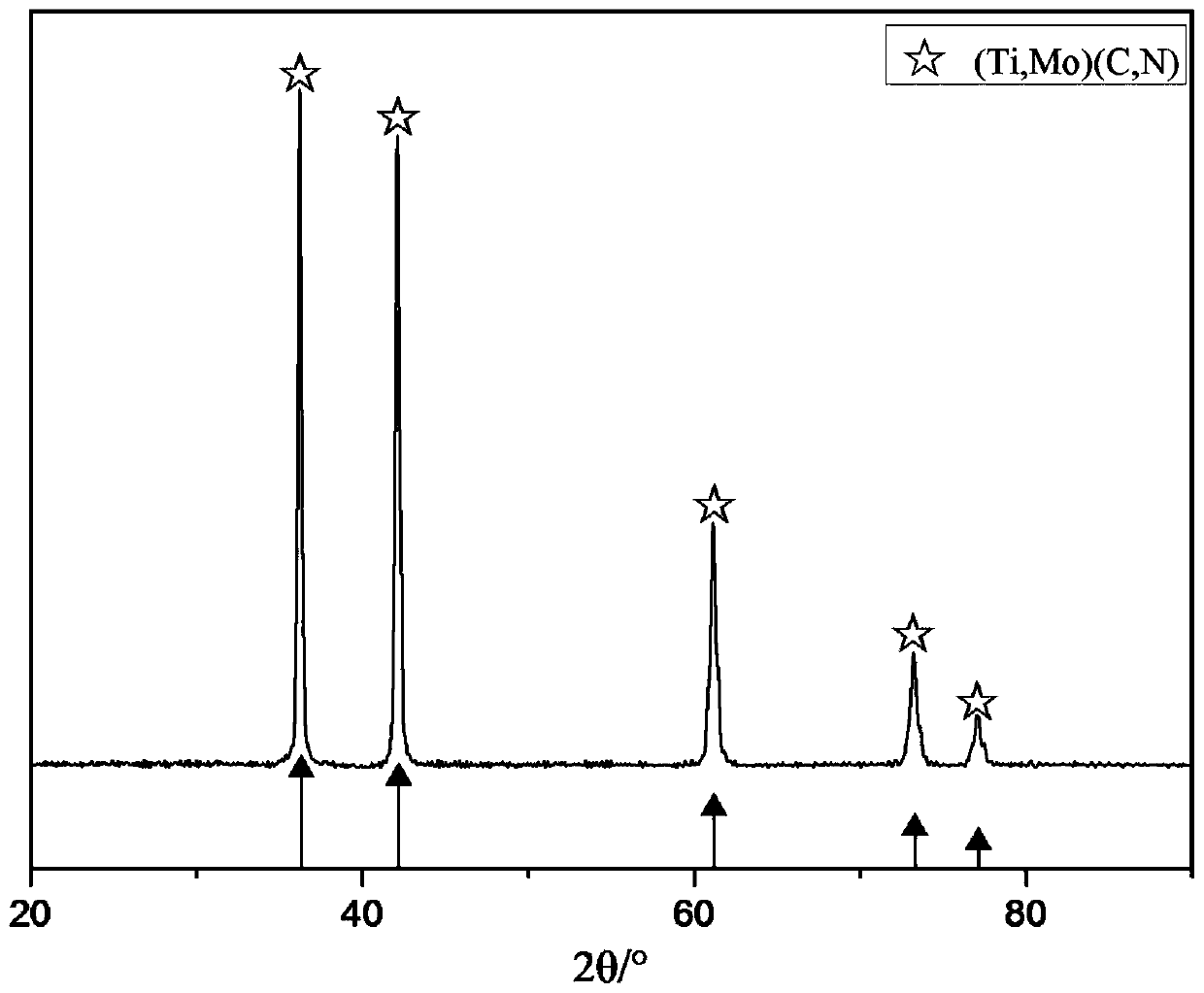

Embodiment 1

[0048] Weigh 755g of TiC powder and 245g of Mo powder. Put titanium carbide powder in a graphite boat and compact it, then put it into a vacuum sintering furnace for purification, the purified massive titanium carbide is crushed by a crusher, and then put into a dry ball mill for ball milling. The alloy used in the ball milling process The diameter of the ball is 20 mm, the ratio of ball to material is 5:1, mixed and ball milled for 10 h, and then sieved on a vibrating sieve with an aperture of 150 μm. The above-mentioned titanium carbide powder and molybdenum powder were mixed in a mixer. The diameter of the alloy ball in the mixer was 10 mm, the ratio of ball to material was 8:1, and the mixing ball milled for 64 hours.

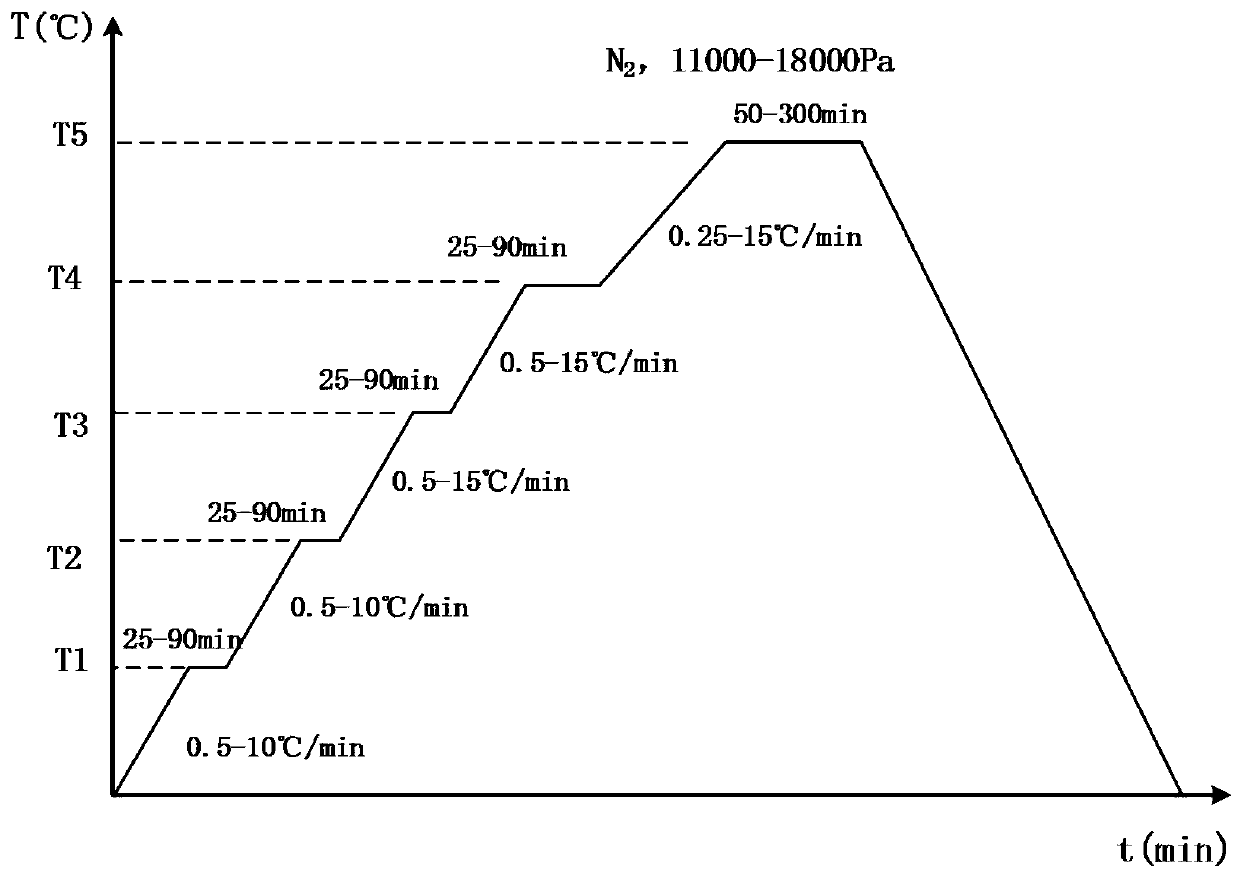

[0049] Put the prepared charge into the graphite boat for compaction, then put it into the vacuum carbonization furnace, start the vacuum pump, and when the vacuum degree is less than 30Pa, power on and heat up. During the heating process, the temperature f...

Embodiment 2

[0057] Weigh 450g of TiO 2 powder, 300g of TiC powder, 100g of Mo powder, 100g of WC powder and 50g of C powder. Put titanium carbide powder and titanium nitride powder in a graphite boat and compact them, and then put them into a vacuum sintering furnace for purification. The purified massive titanium carbide is crushed by a crusher, and then put into a dry ball mill for ball milling. The alloy balls used in the process have a diameter of 10 mm, a ball-to-material ratio of 8:1, mixed ball mills for 8 hours, and then sieved on a vibrating sieve with an aperture of 150 μm. Then, the above-mentioned mixed powder of titanium carbide, titanium nitride and molybdenum powder and tungsten carbide powder were mixed in a mixer. The diameter of the alloy ball in the mixer was 10 mm, the ratio of ball to material was 10:1, and the mixing ball milled for 64 hours.

[0058] Put the prepared charge into the graphite boat for compaction, then put it into the vacuum carbonization furnace, st...

Embodiment 3

[0066] Weigh 450g of TiC powder, 100g of TiO powder, 80g of Mo powder, 100g of WC powder, 50g of NbC powder, 50g of TaC and 20g of Cr 3 C 2 pink. Put titanium carbide powder in a graphite boat and compact it, then put it into a vacuum sintering furnace for purification, the purified massive titanium carbide is crushed by a crusher, and then put into a dry ball mill for ball milling. The alloy used in the ball milling process The diameter of the ball is 10 mm, the ratio of ball to material is 10:1, mixed and ball milled for 10 h, and then sieved on a vibrating sieve with an aperture of 150 μm. The above-mentioned titanium carbide, titanium oxide powder and molybdenum powder were mixed in a mixer. The diameter of the alloy ball in the mixer was 6.25 mm, the ratio of ball to material was 10:1, and the mixing ball milled for 72 hours.

[0067] Put the prepared charge into the graphite boat for compaction, then put it into the vacuum carbonization furnace, start the vacuum pump, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com