Spraying method of wear-resistant coating on roll surface of technology roller of cold rolling unit

A wear-resistant coating, process roller technology, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the application limitation, incompetent cold rolling process, poor wear resistance of thermal spray coating and other problems, to achieve excellent wear resistance, high bonding strength, and the effect of meeting the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The spraying method of the wear-resistant coating on the roll surface of the process roll of the cold rolling mill of the present invention comprises supersonic flame spraying equipment and CO 2 Laser, it is characterized in that this method comprises the steps:

[0012] Step 1. Perform thermal spraying pretreatment on the surface of the process roll substrate, and use organic solvents to clean, preheat, dehumidify, degrease and activate;

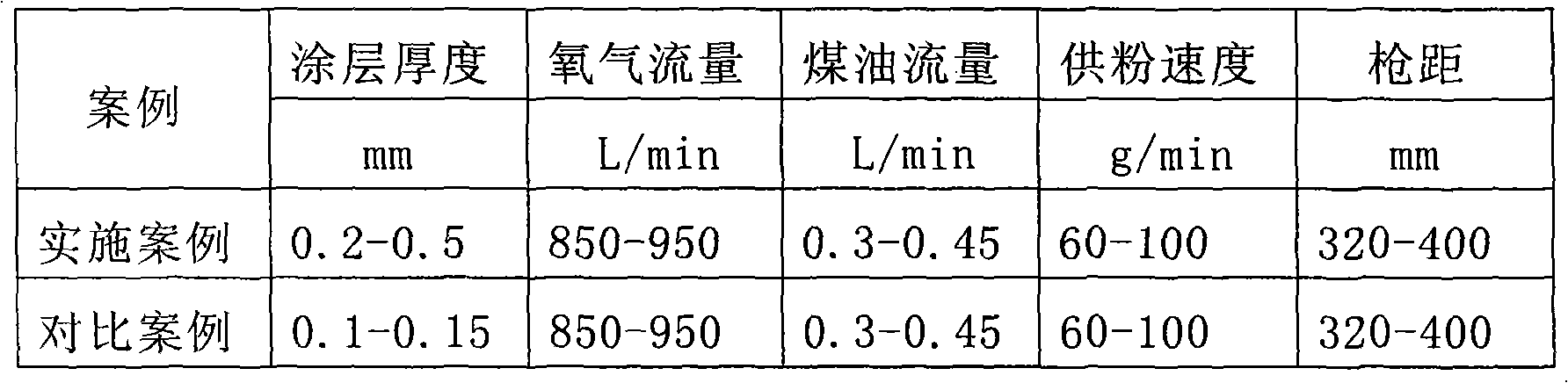

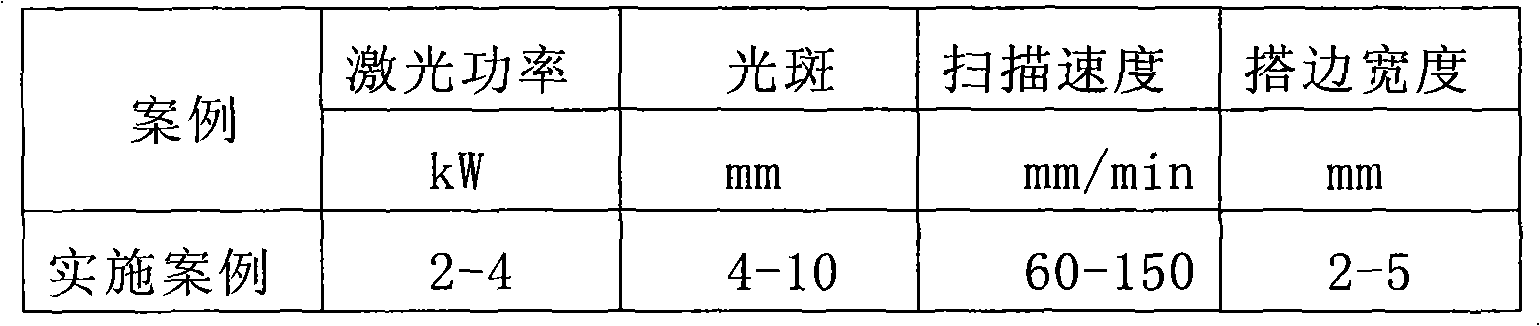

[0013] Step 2. Set the working parameters of the supersonic flame spraying equipment, the oxygen flow rate is 850-950 liters / minute, the kerosene flow rate is 0.30-0.45 liters / minute, the spraying distance is 320-400mm, and the powder supply speed for thermal spraying is 60 -100 g / min;

[0014] Step 3, using the supersonic flame spraying equipment to spray the WC cermet alloy powder material on the surface of the process roll substrate. The WC content in the WC cermet alloy powder material is 73-88%, and the alloy composition is mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com