The Method of Overlay Welding Strengthening on the Surface of the Piercing Machine of Seamless Steel Pipe

A technology of surface surfacing and seamless steel pipes, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of fatigue cracking, large number of use, high cost, etc., to improve performance, reduce production cost, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

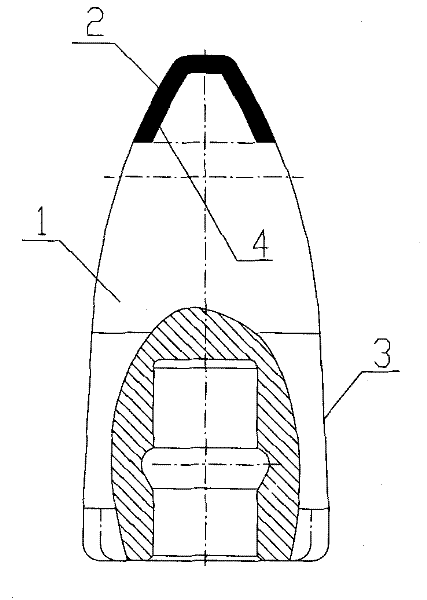

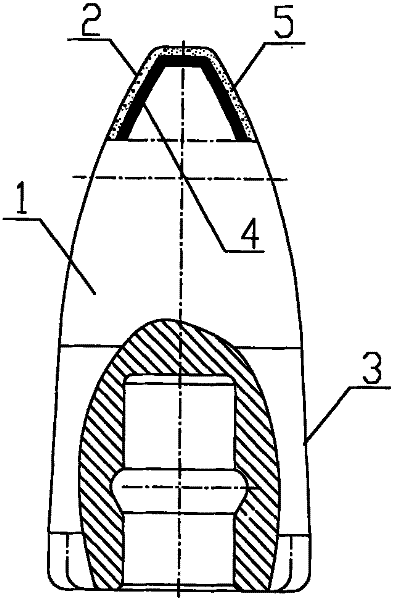

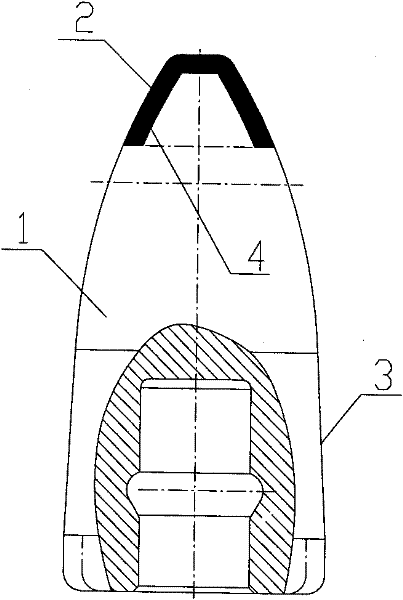

[0018] Such as figure 1 and figure 2 As shown, the method for strengthening the surface of the seamless steel pipe piercer by overlay welding of the present invention, the plug 1 is a casting or forging, and the method includes the following steps:

[0019] Step 1. According to the technical size data of plug 1, carry out preliminary machining on the blank of plug 1, cut the head 2 of the plug to have a surfacing thickness of 2-5mm, and reserve a finishing allowance of 0.5-1mm for the body 3 of the plug;

[0020] Step 2: Perform routine flaw detection on the blank of plug 1 after preliminary machining to find hidden cracks or material linear defects, and rework the plug blank if there are above-mentioned defects;

[0021] Step 3: Use Ni-based, Co-based or cermet alloy materials to carry out surfacing welding on the cut plug head 2 to form a surfacing layer 4. The surfacing welding adopts a plasma arc surfacing method, and ensures that the surfacing layer 4 and the plug head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com