Metal ceramic alloy preparation method and product thereof

A cermet and alloy technology, applied in the field of cermet sintering, can solve the problems of knife edge damage and poor controllability, and achieve the effects of improving bonding strength, reducing production cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

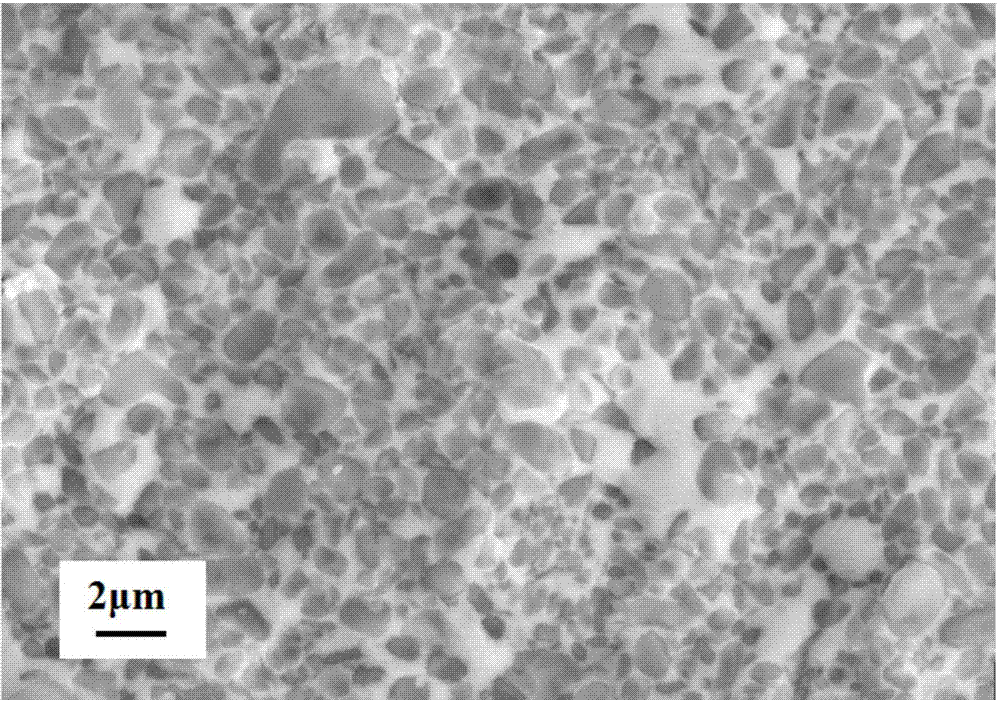

Embodiment 1

[0040] A method for preparing a cermet alloy, comprising the following steps:

[0041] (1) Ingredients: The mass percentages of the raw material powders used in this example are: 50%TiCN, 4%TiC, 9%TaC, 11%WC, 4%Mo 2 C, 1%Cr 3 C 2 , 15%Co, 6%Ni. Among them, TiCN, TaC, WC, Cr 3 C 2 , The average particle size of TiC powder is 1.5μm; Mo 2 The average particle size of the C powder is 2 μm; the average particle size of the Co and Ni powders is 1 μm.

[0042](2) Mixing and pressing: Prepare 500g of mixed powder according to the above mass percentage, add 3% polyethylene glycol as a molding agent, and then place it in a small roller ball mill for ball milling (wet milling). After ball milling, the slurry is dried and prepared. granules, and then pressed into green bodies.

[0043] (3) Sintering: put the above green body into the sintering furnace and sinter according to the following sintering process:

[0044] a. Low-temperature removal of molding agent: from room temperatur...

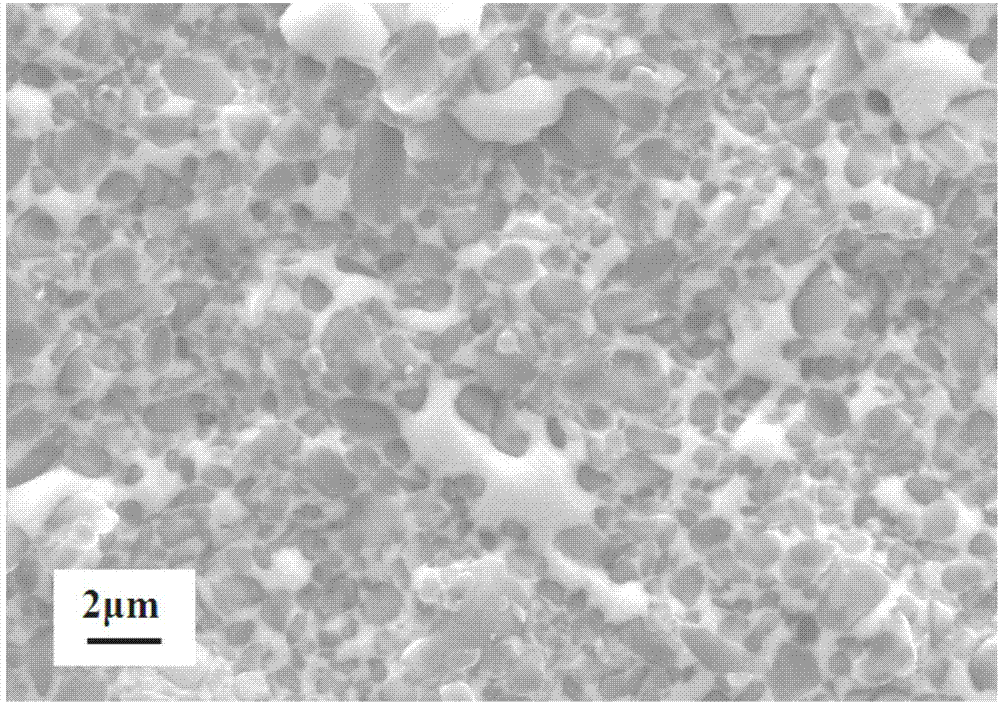

Embodiment 2

[0052] A method for preparing a cermet alloy, comprising the following steps:

[0053] (1) Ingredients: The mass percentages of the raw material powders used in this example are: 55%TiCN, 3%TiC, 11%TaC, 12%WC, 10%Mo 2 C, 2%Cr 3 C 2 , 7%Co. Among them, the average particle size of TiCN and TiC powders is 1.5 μm; TaC and Cr 3 C 2 The average particle size of powder is 2 μm; the average particle size of WC powder is 0.5 μm; Mo 2 The average particle size of the C powder is 3 μm; the average particle size of the Co powder is 1 μm.

[0054] (2) Mixing and pressing: Prepare 500g of mixed powder according to the above mass percentage, add 3% polyethylene glycol as a molding agent, and then place it in a small roller ball mill for ball milling (wet milling). After ball milling, the slurry is dried and prepared. granules, and then pressed into green bodies.

[0055] (3) Sintering: put the above green body into the sintering furnace and sinter according to the following sintering...

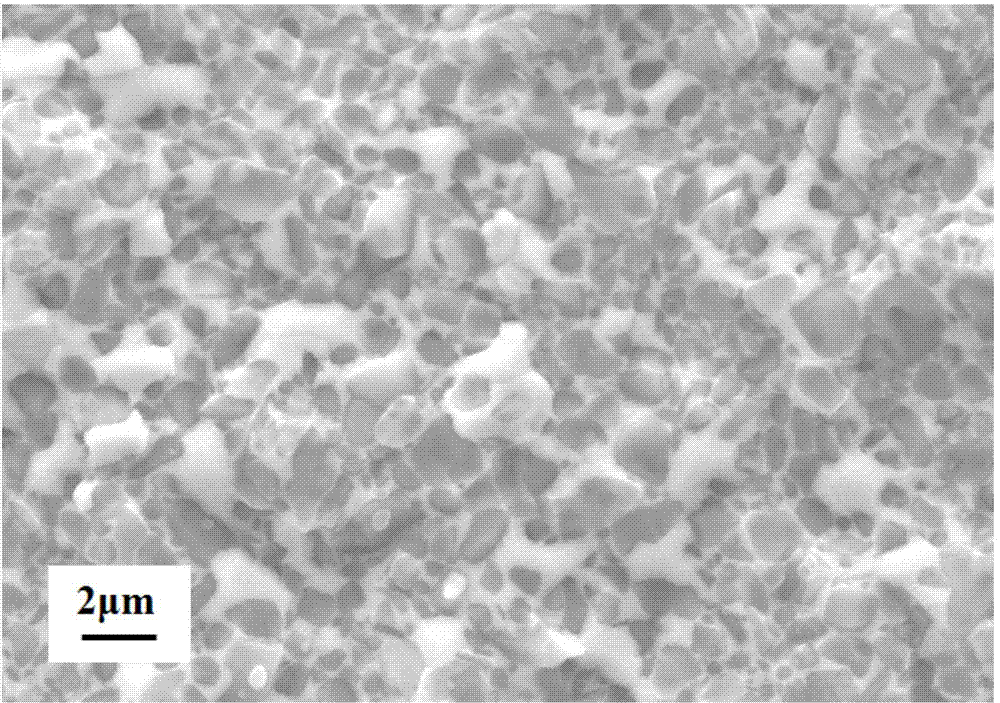

Embodiment 3

[0064] A method for preparing a cermet alloy, comprising the following steps:

[0065] (1) Ingredients: The mass percentage of each raw material powder used in this example is: 42%TiCN, 9%TiC, 9%TaC, 17%WC, 6%Mo 2 C, 2%Cr 3 C 2 , 15%Ni. Among them, the average particle size of TiCN and TiC powders is 1 μm; Mo 2 The average particle size of C powder is 2μm; WC, Cr 3 C 2 , TaC, and Ni powders have an average particle size of 1.5 μm.

[0066] (2) Mixing and pressing: Prepare 500g of mixed powder according to the above mass percentage, add 3% polyethylene glycol as a molding agent, and then place it in a small roller ball mill for ball milling (wet milling). After ball milling, the slurry is dried and prepared. granules, and then pressed into green bodies.

[0067] (3) Sintering: put the above green body into the sintering furnace and sinter according to the following sintering process:

[0068] a. Low-temperature removal of molding agent: from room temperature to the vapo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com