NbC-based lightweight metal cermet alloy with high wearing resistance and toughness and preparation method thereof

A cermet, strong toughness technology, applied in the field of cermet material preparation, can solve the problems of high specific weight, insufficient high temperature wear resistance of WC base, high toxicity of WC-Co composite powder, etc., to improve alloy hardness and high temperature resistance, Effect of improving wear resistance and flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

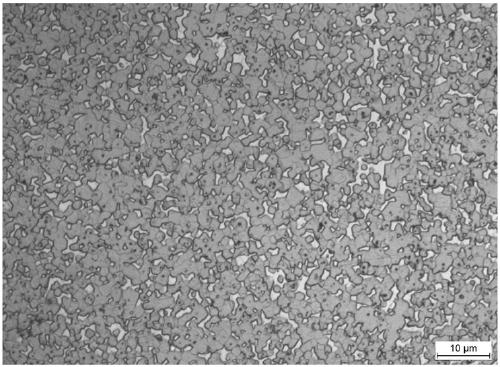

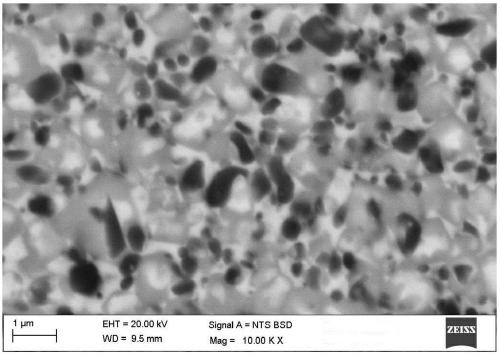

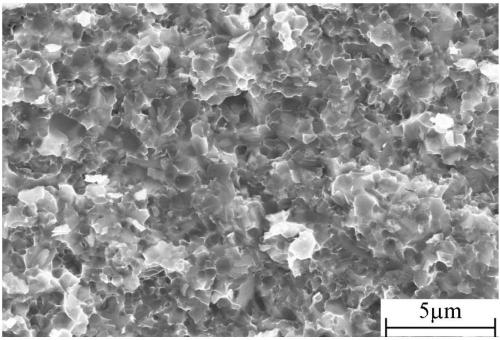

Embodiment 1

[0037] NbC micron powder (particle size is FSSS1.2) weighs 595g, (Nb, 5Mo, 1Zr) C submicron powder (particle size is FSSS0.8) weighs 100g, powder particle size is FSSS0.8 WC powder weighs 100g, powder Ni powder with a particle size of FSSS1.2 weighs 150g, Mo 2 C micron powder (particle size is FSSS1.5) weighs 50g, ZrC micron powder (particle size is FSSS1.2) weighs 2.5g, Cr 3 C 2 The micron powder (particle size is FSSS1.2) weighs 2.5g. Weigh 800ml of absolute ethanol as the ball milling medium, weigh 20g of polyvinyl alcohol as the molding agent, and weigh 1.5g of acetholamine as the dispersant.

[0038] (1) Ball mill mixing: Put the raw material powder prepared according to step (1) into YG6X alloy balls with a diameter of 10mm and absolute ethanol as the ball milling medium, and add 1.5g of dispersant acethamine and 20g of forming agent polyvinyl alcohol at the same time Put it into a clean stainless steel ball mill jar, and then ball mill it on a roller ball mill for 72...

Embodiment 2

[0045] NbC micron powder (particle size is FSSS1.2) weighs 646g, the WC powder that powder particle size is FSSS0.8 weighs 120g, the Ni powder that powder particle size is FSSS1.2 weighs 180g, Mo 2 C micron powder (particle size is FSSS1.5) weighs 50g, ZrC micron powder (particle size is FSSS1.2) weighs 4g. Weigh 800ml of absolute ethanol as the ball milling medium, weigh 20g of polyvinyl alcohol as the molding agent, and weigh 4g of acetholamine as the dispersant.

[0046] (1) Ball mill mixing: Put the raw material powder prepared according to step (1) into YG6X alloy balls with a diameter of 10mm and absolute ethanol as the ball milling medium, and add 1.5g of dispersant acethamine and 20g of forming agent polyvinyl alcohol at the same time Put it into a clean stainless steel ball mill jar, and then ball mill it on a roller ball mill for 96 hours, the ball-to-material ratio is 8:1, and the ball milling speed is 70r / min. After the wet abrasive is taken out, dry it in a vacuu...

Embodiment 3

[0053] NbC submicron powder (particle size is FSSS0.8) weighs 665g, (Nb,5Mo,1Zr)C submicron powder (particle size is FSSS0.8) weighs 50g, powder particle size is FSSS1.2 WC powder weighs 100g, Ni powder with powder particle size of FSSS1.2 weighs 120g, Mo 2 C micron powder (particle size is FSSS1.5) weighs 60g, ZrC micron powder (particle size is FSSS1.2) weighs 2.5g, VC micron powder (particle size is FSSS1.0) weighs 2.5g. Weigh 800ml of absolute ethanol as the ball milling medium, weigh 20g of polyvinyl alcohol as the molding agent, and weigh 7.5g of acetholamine as the dispersant.

[0054] (1) Ball mill mixing: Put the raw material powder prepared according to step (1) into YG6X alloy balls with a diameter of 10mm and absolute ethanol as the ball milling medium, and add 1.5g of dispersant acethamine and 20g of forming agent polyvinyl alcohol at the same time Put it into a clean stainless steel ball mill jar, and then mill it on a roller ball mill for 144 hours with a ball-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com