Cotton yarn dyeing device

A dyeing device and cotton yarn technology, applied in the field of cotton yarn, can solve the problems of wasting dyestuffs and inability to guarantee dyeing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

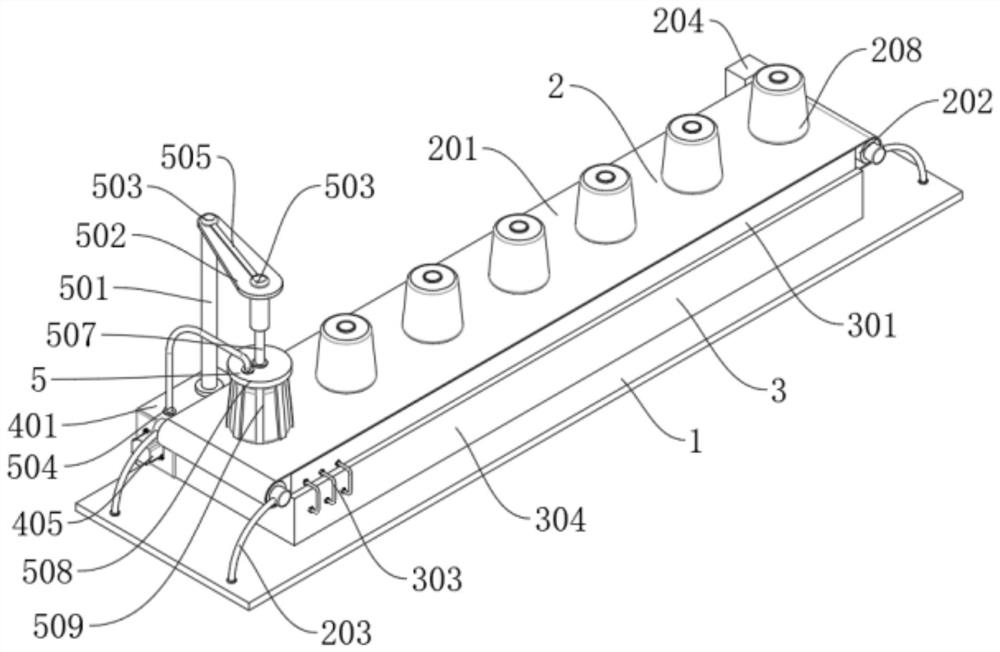

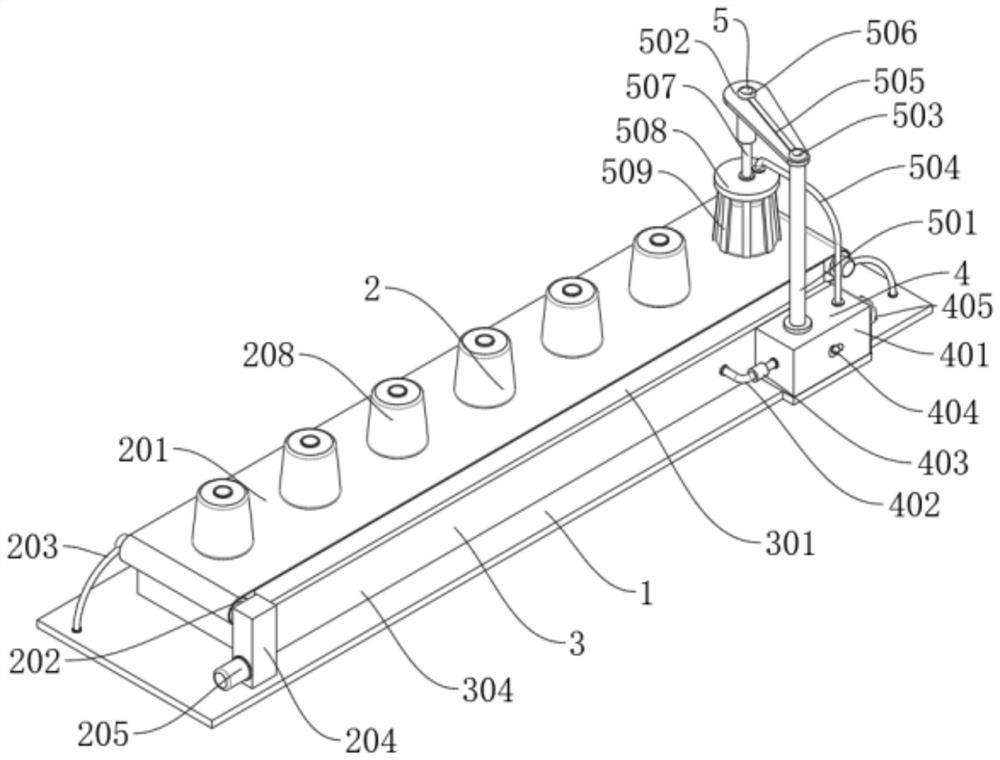

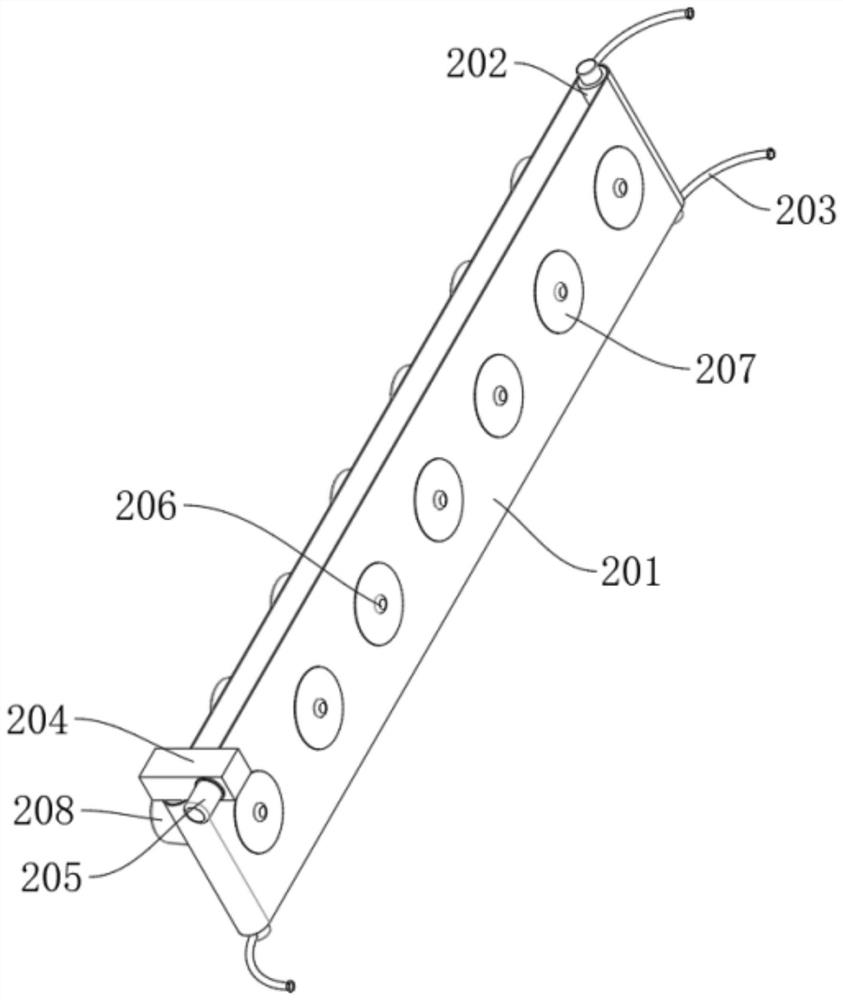

[0031] see Figure 1-Figure 6 , the present invention provides a cotton yarn dyeing device: comprising a bottom plate 1, a yarn feeding mechanism 2, a return mechanism 3, and a water absorption mechanism 4, a backflow mechanism 3 is installed on the upper part of the bottom A water absorption mechanism 4 is installed on the rear side of the mechanism 3, and also includes a dyeing mechanism 5 for clamping and dyeing cotton yarn rolls. The dyeing mechanism 5 includes a support column 501, a connecting plate 502, a controller 503, a feeding pipe 504, a connecting line 505, Timer 506, electric push rod 507, intermediate turntable 508, splint 509, retractable needle 510, nozzle 511, support column 501 is connected to the upper side of water absorption mechanism 4 by bolts, and one end of support column 501 is connected to connecting plate 502 by bolts A controller 503 is installed on one end of the upper surface of the connecting plate 502, and a timer 506 is installed on the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com