A kind of dyeing and finishing process of acetate fiber and protein fiber silk fabric

A technology of acetate fiber and protein fiber, which is applied in the field of dyeing and finishing, can solve the problems of easy color difference and poor fabric dyeing quality, and achieve the effect of not easy color difference, not easy to decolorize, and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

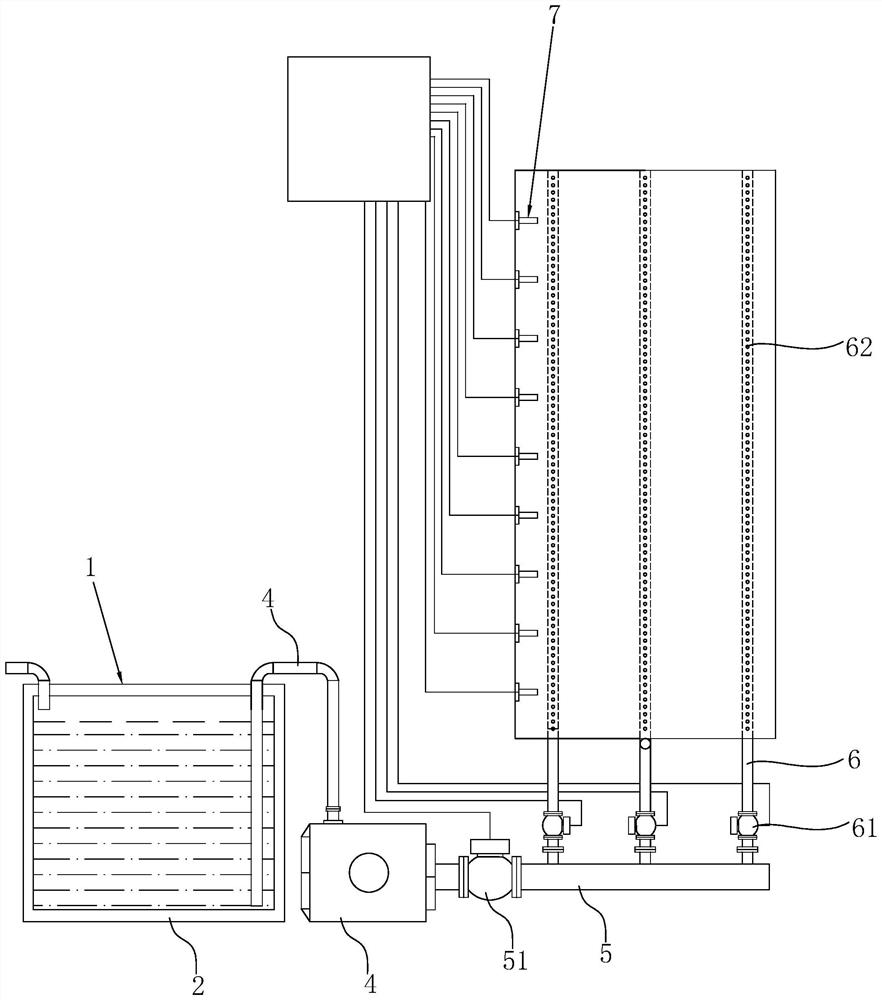

Image

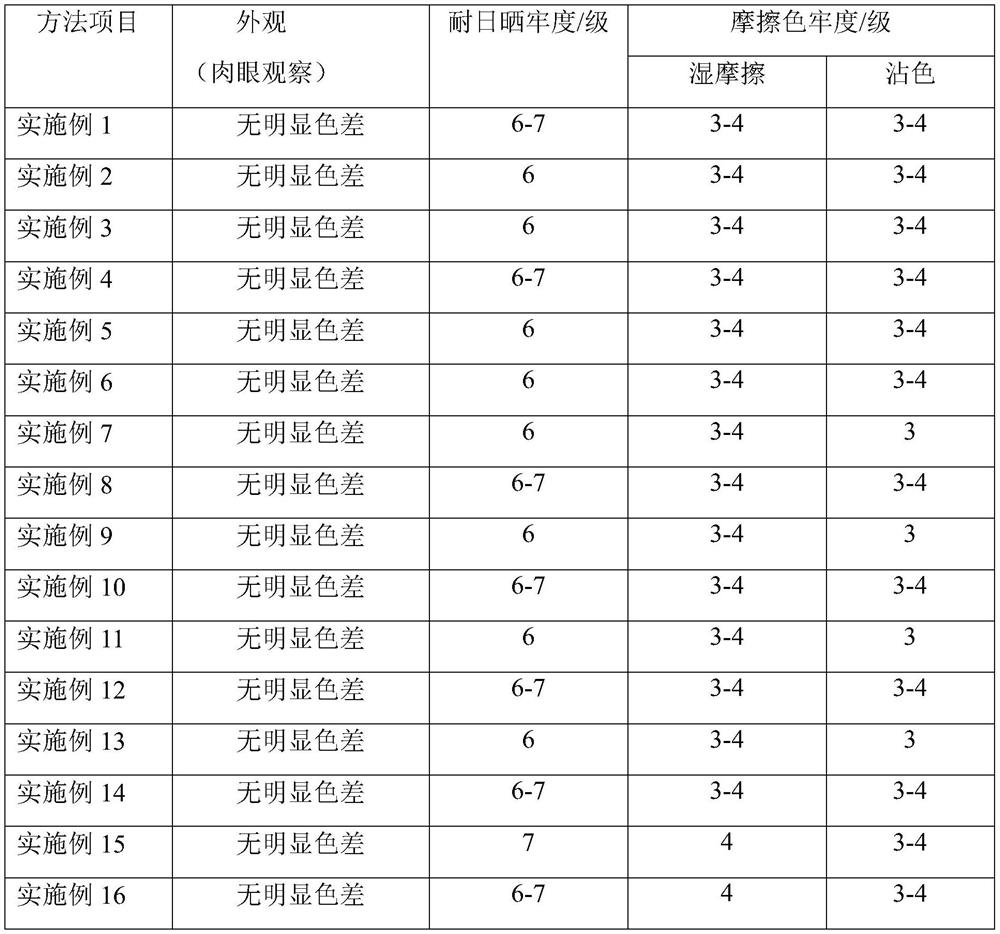

Examples

Embodiment 1

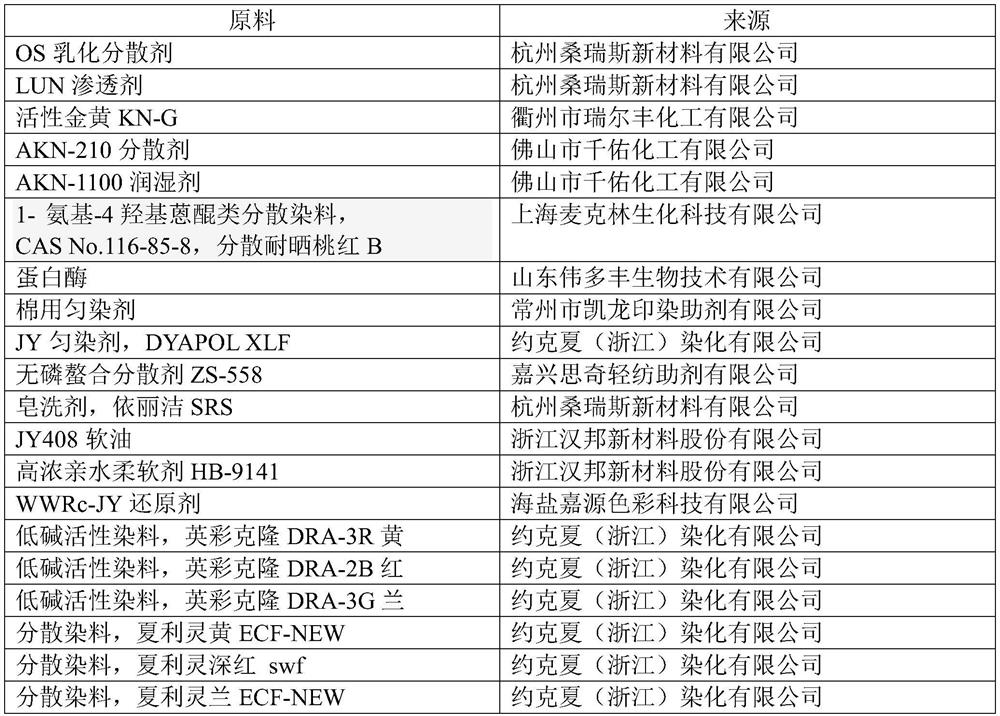

[0078] A dyeing and finishing process of acetate fiber and protein fiber silk fabric disclosed in the present application comprises the following steps:

[0079] Step 1, selecting the acetate silk J3705-2 in the raw material 1, first refining the acetate silk J3705-2, placing the acetate silk J3705-2 in 0.4g / L protease, 2.0g / L soda ash, 1.0g / l infiltration agent LUN, the water temperature is 60°C, the pH value is 10, and the liquor ratio is 1:10 for 60 minutes, and then the acetate silk J3705-2 fabric is placed in the overflow dyeing machine. The concentration of the auxiliary agent in the overflow dyeing machine is: 2.0g / L of OS emulsification and dispersant, 2.0g / L of LUN penetrant, liquor ratio 1:10, water temperature 80℃, after soaking the acetate silk J3705-2 fabric for 30min, wash twice with deionized water at 40℃ , each cleaning time is 10min, spare;

[0080] In step 2, the two-bath dyeing method is used to dye the acetate silk J3705-2 fabric pretreated in step 1. The ...

Embodiment 2

[0099] The difference between Example 2 and Example 1 is: the dyeing formula 1 in Example 1 is replaced by dyeing formula 2: the target dyeing is red, the dosage of Yingcai clone DRA-2B red used is 2%, and the used Xiali Ling deep red swf The dosage is 0.5%.

Embodiment 3

[0101] The difference between Example 3 and Example 1 is that: the dyeing formula 1 in Example 1 is replaced by dyeing formula 3: the target dyeing is blue, the amount of Yingcai clone DRA-3G blue used is 2%, and the used Charlene ECF The dosage of -NEW is 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com