Building steel box girder external prestress buffering device and construction technology

A technology of external prestressing and buffering device, which is applied in the directions of buildings, bridges, bridge parts, etc., can solve the problems of weak stress buffering effect, affecting the stress buffering effect, and easy accumulation of debris.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

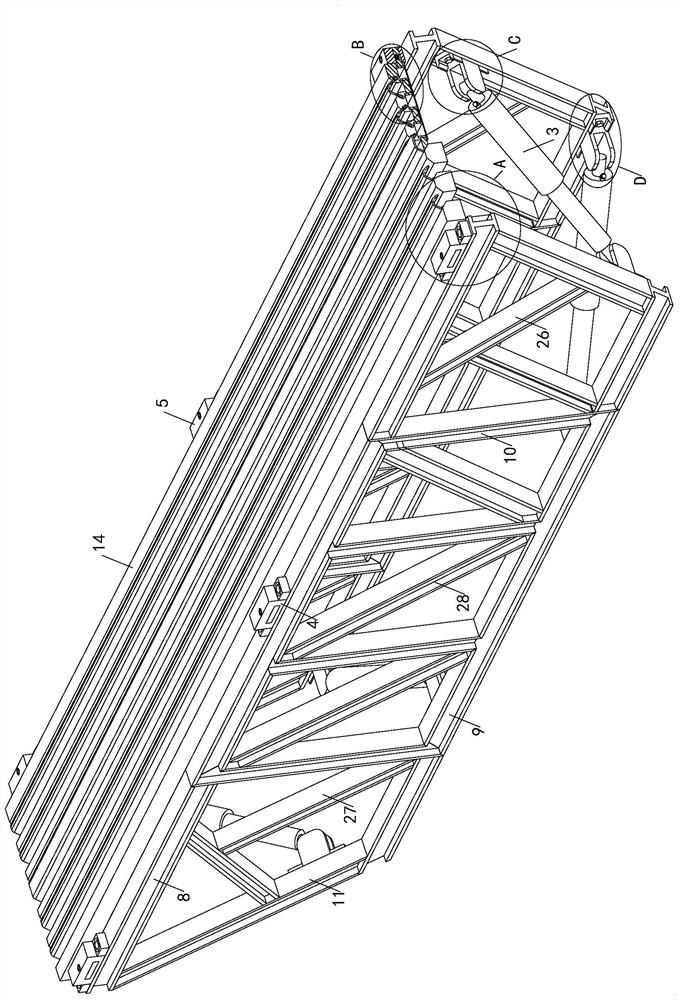

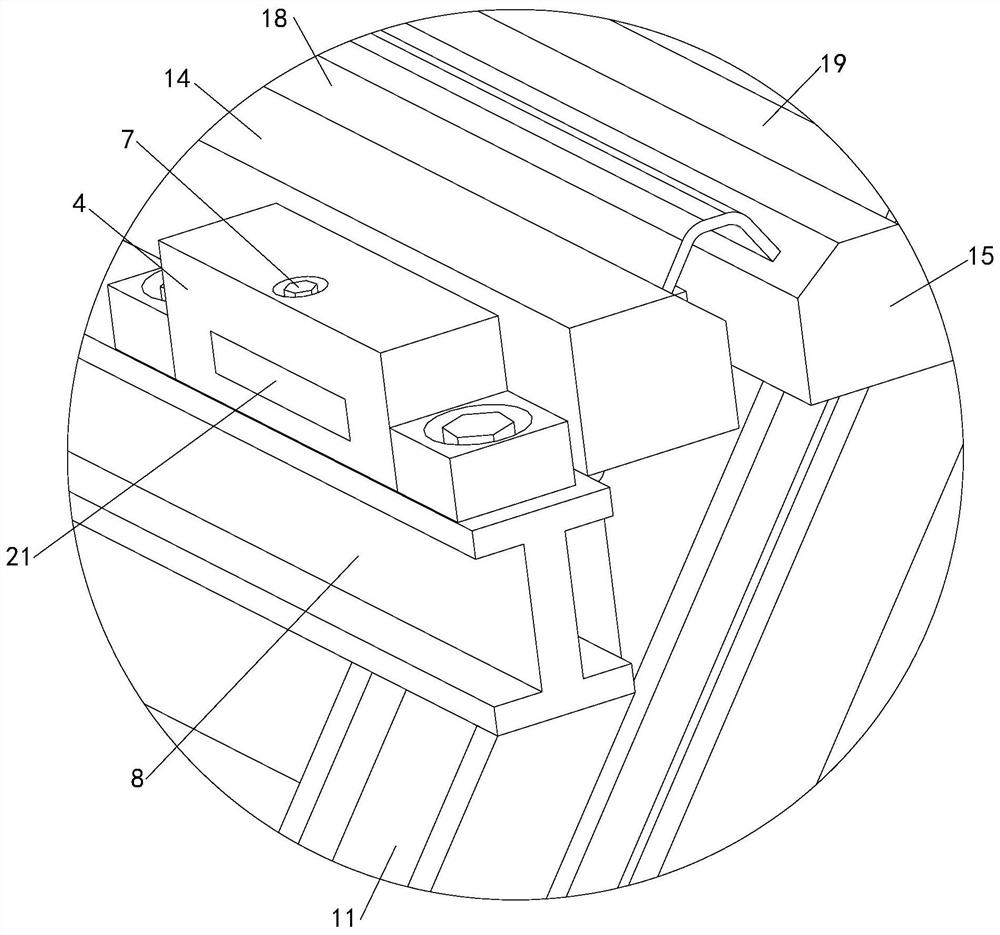

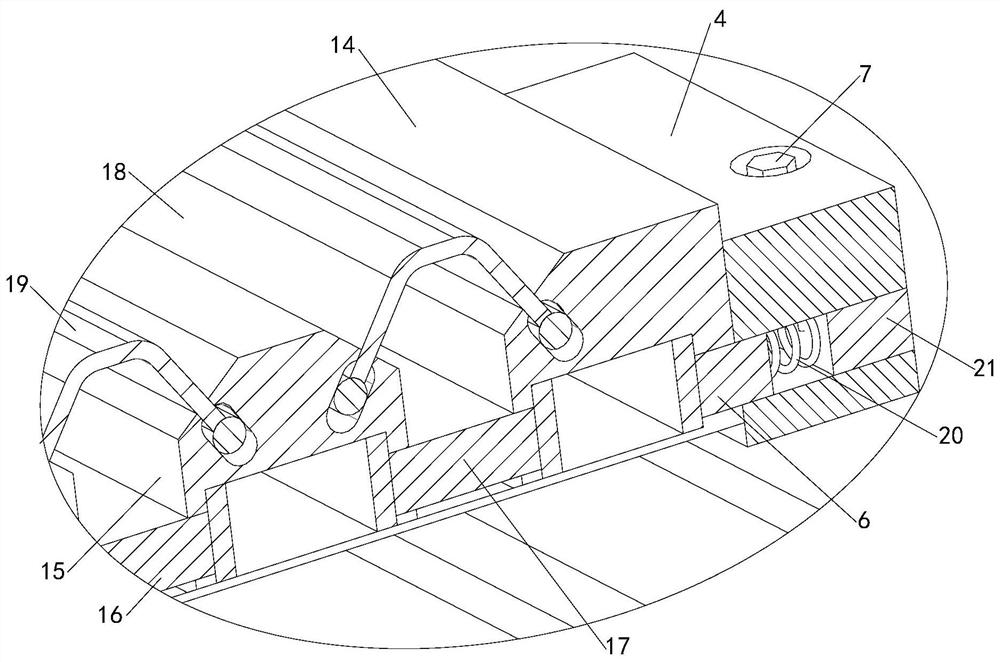

[0037] see Figure 1-7 , an external prestressed buffer device for building steel box girders, including a plurality of telescopic tubes, and two connecting end frames, both of which include an upper beam 8 and a lower beam 9, an upper beam 8 and a lower The beams 9 are connected by a plurality of vertical rods 10, and oblique struts 28 are fixedly connected between every two adjacent vertical rods 10 in the plurality of vertical rods 10, and the top and bottom ends of the oblique struts 28 are respectively connected with The upper beam 8 and the lower beam 9 are fixedly connected to improve the structural strength between the vertical bar 10 and the upper beam 8 and the lower beam 9, and there are two diagonally fixed connections between the upper beam 8 and the lower beam 9 The side bar 11, the front seat cover 4 and the rear seat cover 5 are respectively fixedly connected to the two upper beams 8, and the two hypotenuse bars 11 are fixedly connected with a diagonal strut 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com