Concrete support mounting structure and mounting and dismounting method

A technology for installing structures and concrete, which is applied in basic structure engineering, excavation, construction, etc., and can solve problems such as high construction cost, easy to be poured in concrete, and difficult demolition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

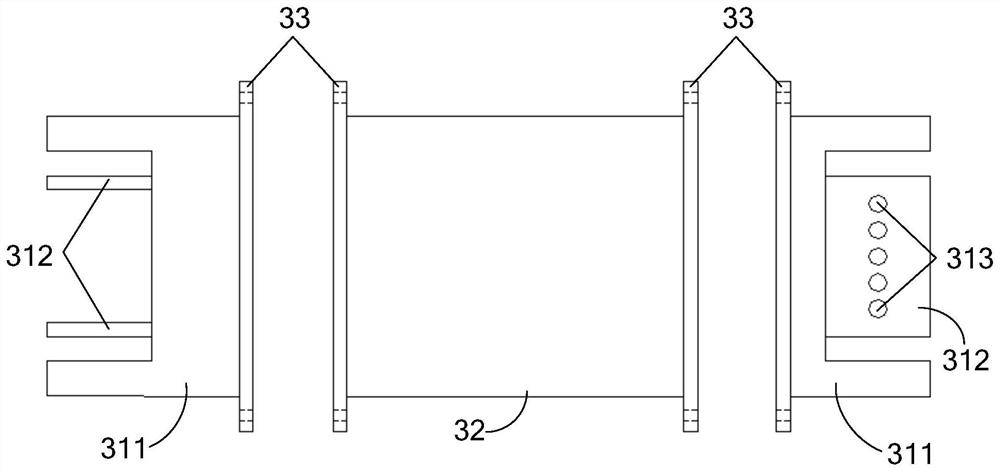

[0057] First preferred embodiment: the second joint assembly 4 also includes a first connecting bolt 43; the protruding portion 413 is provided with a threaded hole 414 for screwing the first connecting bolt 43; the groove portion 423 is provided with There is a through hole 424 through which the first connecting bolt 43 passes.

[0058] Specifically, the protruding portion 413 and the groove portion 423 are both rectangular, and at least one threaded hole 414 is provided on four surfaces of the protruding portion 413, and each threaded hole 414 is located on a corresponding surface. The centerline of the groove part 423 extends to the inside of the protruding part 413 in a direction perpendicular to the corresponding surface, and the four inner walls of the groove part 423 are provided with the through holes 424 at positions corresponding to the threaded holes 414. When the protruding portion 413 is inserted into the groove portion 423, the axes of all the through holes 424 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com