Underpinning protection system for top socket pipeline in underpass construction and construction method

A technology of protection system and construction method, applied in the direction of pipeline support, protection device, excavation, etc., can solve the problem of the large disturbance of the socket and socket pipeline and the inability to ensure the normal use of the socket and socket pipeline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0043]The present invention also provides a specific implementation of the construction method of the underpinning protection system of the top socket pipe in the underpass construction, which includes the following steps:

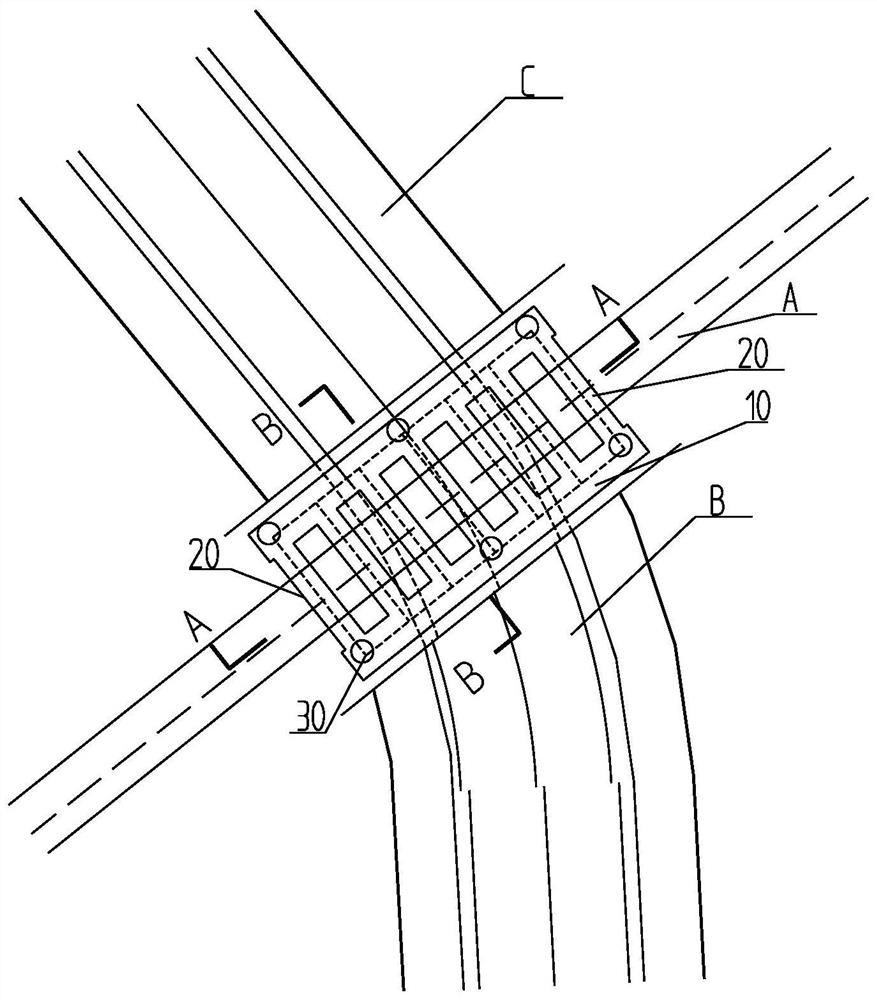

[0044] S1. According to the laying line of the box culvert, it is excavated for the foundation pit C, and at the position of the existing socket pipe A, the bottom of the foundation pit C is flush with the bottom surface of the socket pipe A; specifically, the The foundation pit C is roughly an earth pit with an inverted trapezoidal slope section. In the extension direction of the socket pipe A, the width of the bottom of the foundation pit C is 1.5-2 times the width of the box culvert B to be constructed. In the extending direction of the socket pipe A, the width of the foundation pit C is 2-3 times the diameter and length of the socket pipe A.

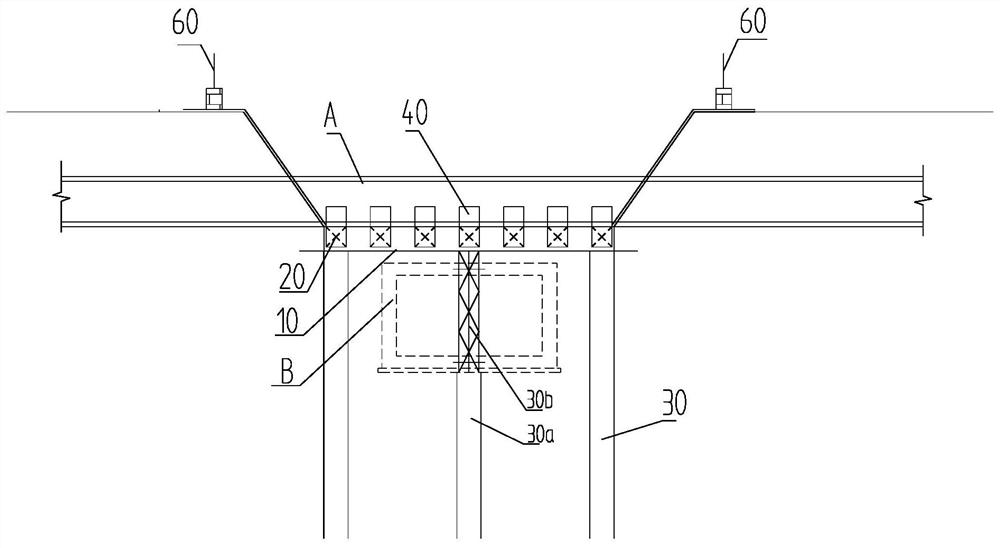

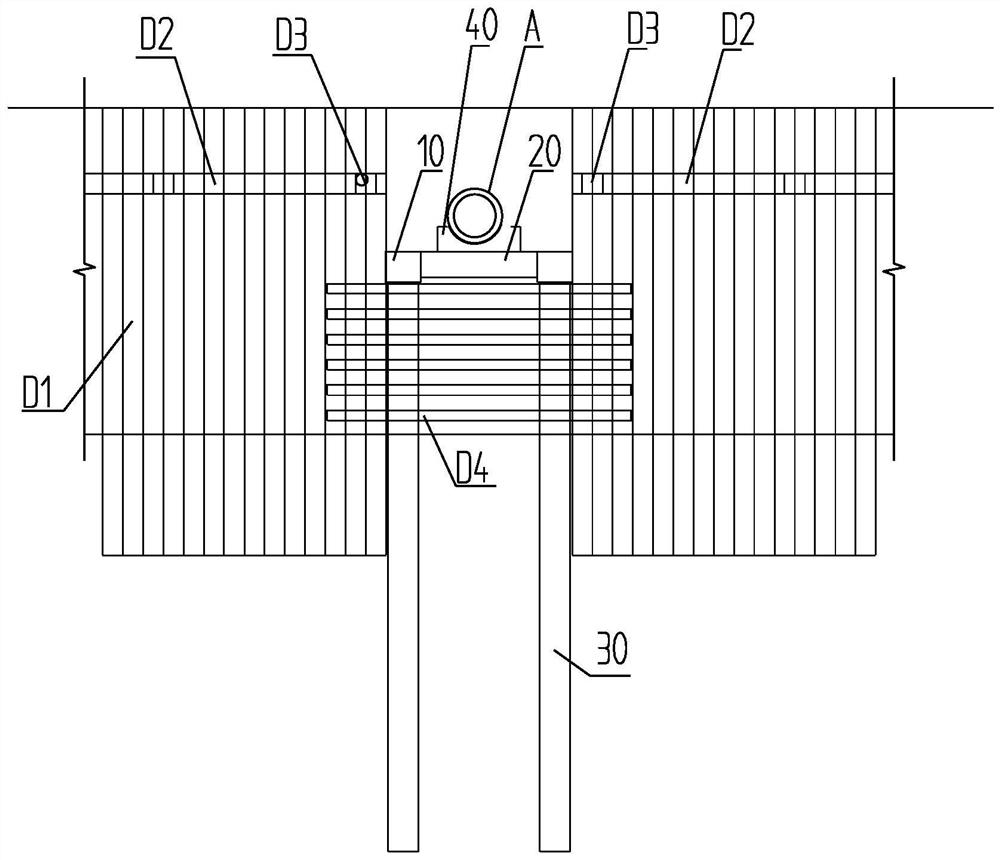

[0045] S2. Constructing at least two cast-in-situ piles 30 arranged at intervals along the extension direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com