Intelligent flue gas and air control system of household garbage incineration equipment

A domestic waste incineration and control system technology, applied in the field of intelligent smoke control system, can solve problems such as large operation fluctuations, uneven combustion, and fire failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

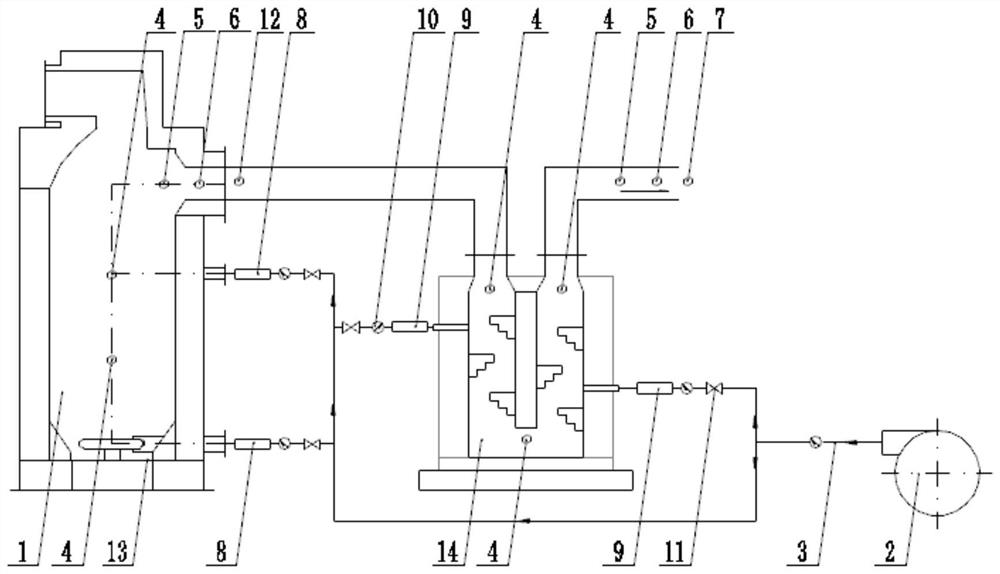

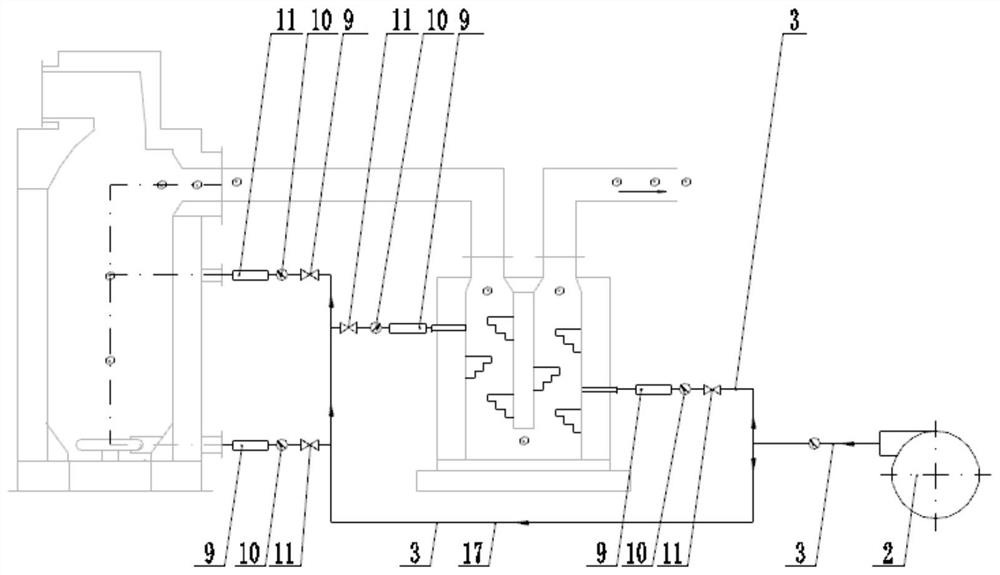

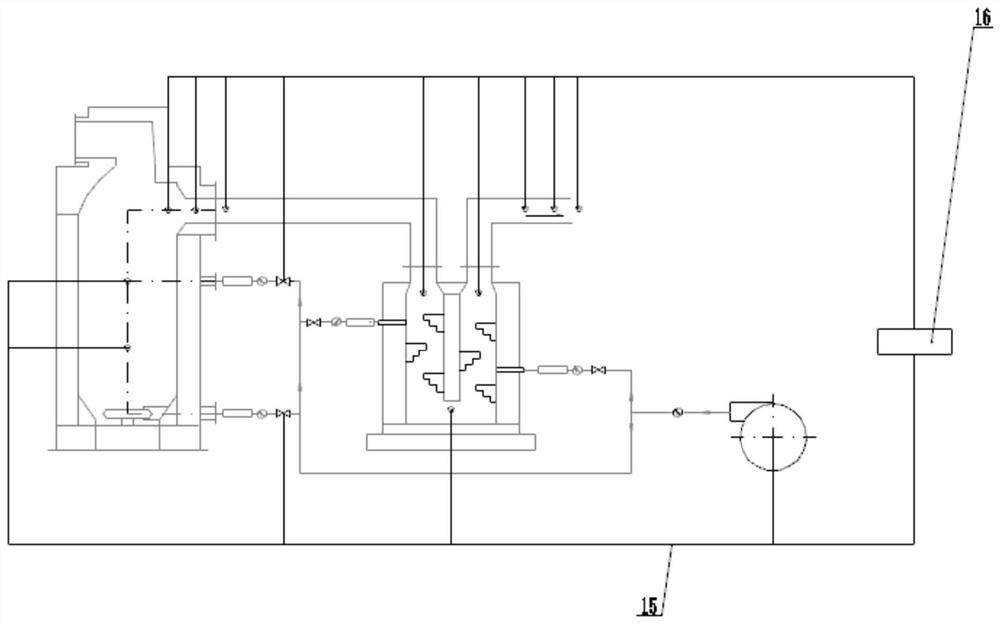

[0013] Such as figure 1 Shown is the structure of the intelligent flue gas control system of domestic waste incinerator, including incinerator 1, oxygen supply fan 2, oxygen supply pipeline system 3, temperature detection instrument 4, flue gas oxygen content detection instrument 5, and negative pressure instrument 6. Negative pressure fan 7, primary air distribution device 8, secondary air distribution device 9, flow indicator 10, flow control valve 11, CO detector 12, furnace material weight feedback device 13, secondary combustion chamber 14, signal transmission System 15, terminal control system 16. The incinerator 1 is connected to the oxygen supply blower 2 through a primary air distribution device 8, a secondary air distribution device 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com