Lube oil solvent refining performance evaluation device

A solvent refining and lubricating oil technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem that it is difficult to accurately determine the operating conditions of the stripping tower, the actual situation of the fluid in the extraction tower cannot be seen, and the position of the interface in the tower is difficult to determine, etc. problem, to achieve the effect of easy determination of operating conditions, high evaluation efficiency, and accurate evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the embodiments.

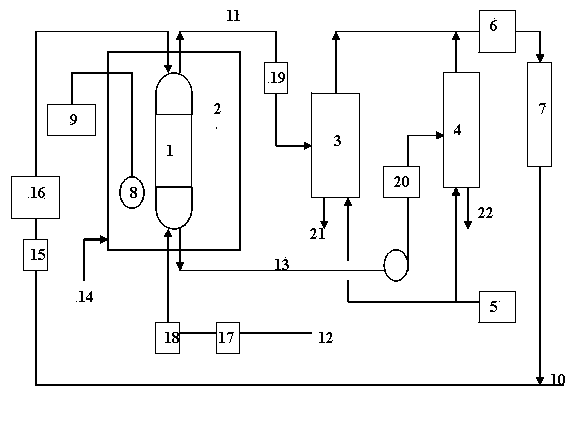

[0025] Such as figure 1 The device for evaluating the solvent refining performance of lubricating oil shown includes an extraction tower 1, a thermostat 2, a raffinate stripper 3, an extract stripper 4, a steam generator 5, a furfural dryer 6 and a solvent recovery tank 7. A cylindrical groove is set in the middle of 2 in the thermostat, and the extraction tower 1 is placed in the groove. An observation window is provided on the front of the thermostat 2, through which the changes of the interface in the extraction tower 1 can be observed, and the constant temperature An electric heating element 8 is arranged in the device 2, and the electric heating element 8 is electrically connected with the temperature controller 9. The upper part of the extraction tower is connected with a solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com