Energy-saving control method for fixed-frequency refrigeration equipment

A technology for energy-saving control and refrigeration equipment, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., and can solve the problem that fixed-frequency compressors cannot drive multiple loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

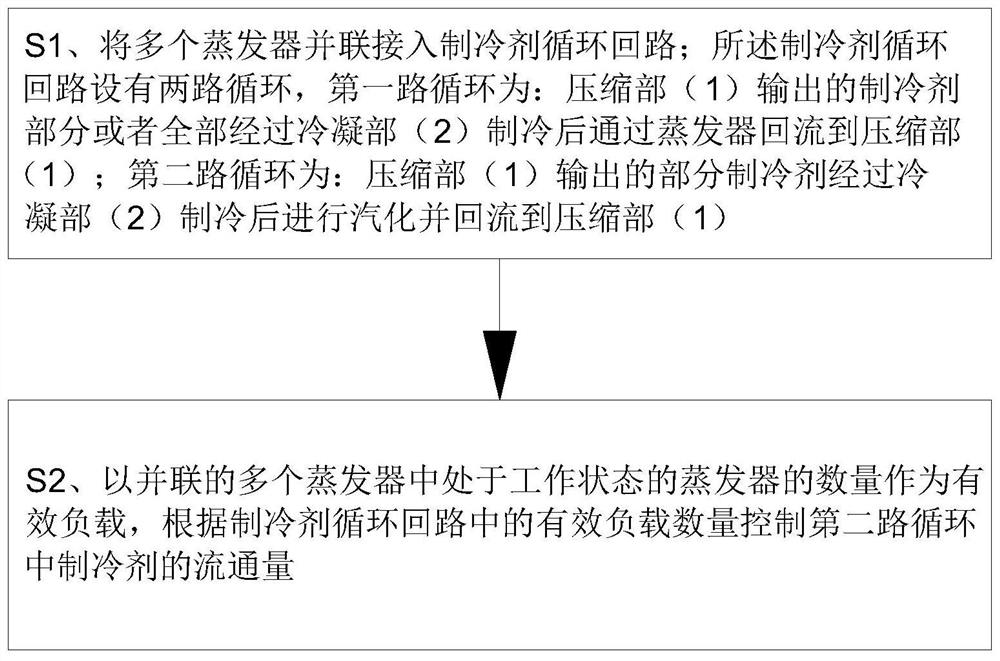

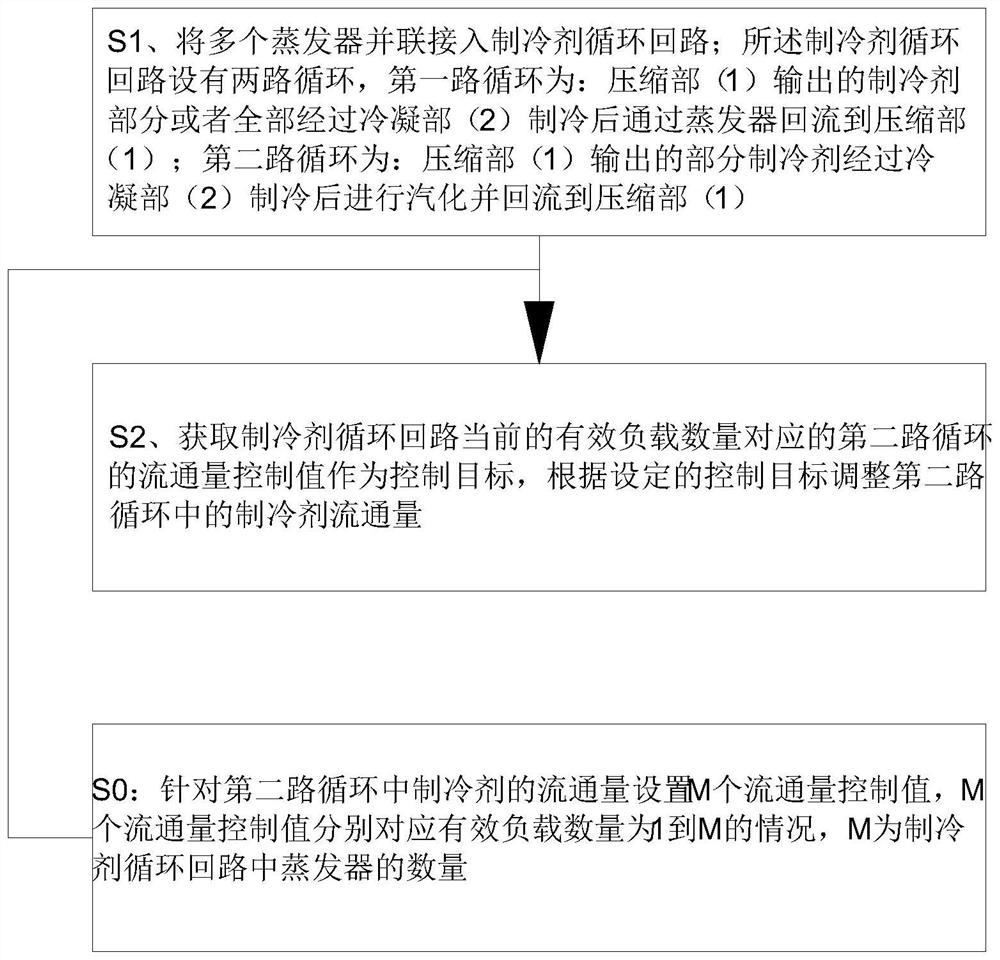

Problems solved by technology

Method used

Image

Examples

Embodiment 1

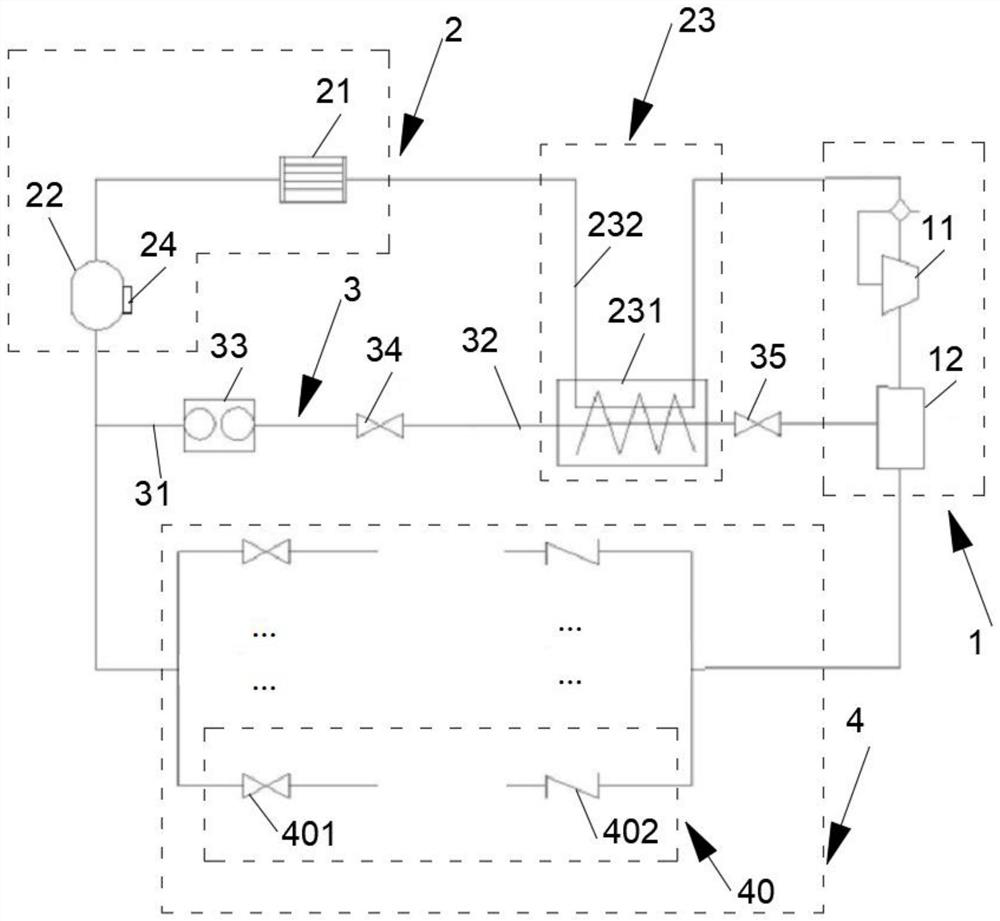

[0078] The refrigerant circulation circuit in this embodiment adopts the first liquid evaporation part 23 , and the load connection part 4 of the device includes three evaporation units 40 .

[0079] In this embodiment, the load connecting portion 4 is connected with three evaporators, namely evaporator A, evaporator B and evaporator C. Before the equipment works, the ambient temperature of the environment where the evaporator A, the evaporator B and the evaporator C are located is all between 35°C and 43°C.

[0080] In this embodiment, taking the opening degree of the first valve 34 as the flow control value, the corresponding relationship between the number of effective loads and the working state of the first valve 34 is shown in Table 1 below.

[0081] Table 1: Correspondence between the number of effective loads and the working state of the first valve 34

[0082] Payload Quantity The opening degree of the first valve 34 3 0 2 3 1 3 / 4

[0...

Embodiment 2

[0088] The refrigerant circulation circuit in this embodiment adopts the second liquid vaporizing part 23 , and the load connection part 4 of the device includes three evaporating units 40 .

[0089] In this embodiment, the load connecting portion 4 is connected with three evaporators, namely evaporator A, evaporator B and evaporator C. Before the equipment works, the ambient temperature of the environment where the evaporator A, the evaporator B and the evaporator C are located is all between 35°C and 43°C.

[0090] In this embodiment, taking the working state of the third valve 235 as the flow control value, the corresponding relationship between the effective load quantity and the working state of the third valve 235 is shown in Table 1 below.

[0091] Table 1: Correspondence between the number of effective loads and the working state of the third valve 235

[0092] Payload Quantity Working state of the third valve 235 3 cut off 2 Intermittent condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com