Transposed conductor forging equipment

A technology of transposition wires and equipment, which is applied in coil manufacturing and other directions, and can solve the problems of small application range, expensive imported equipment, and complicated operation of domestic equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

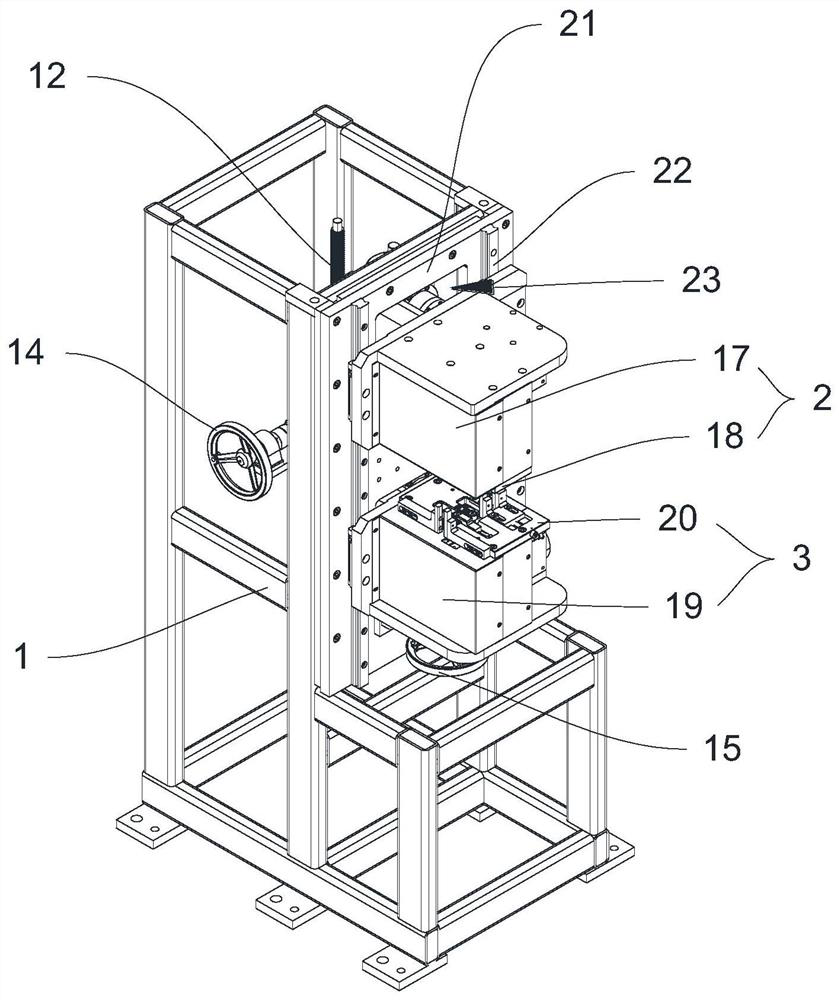

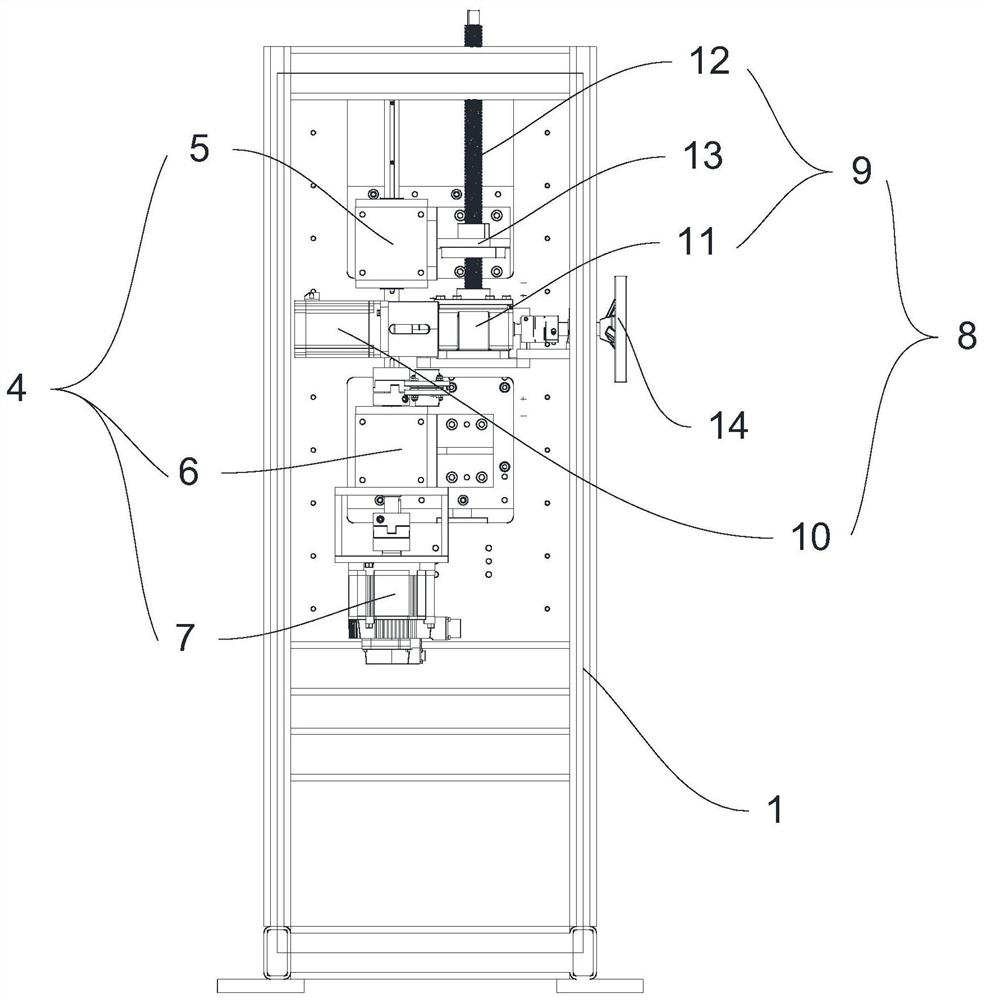

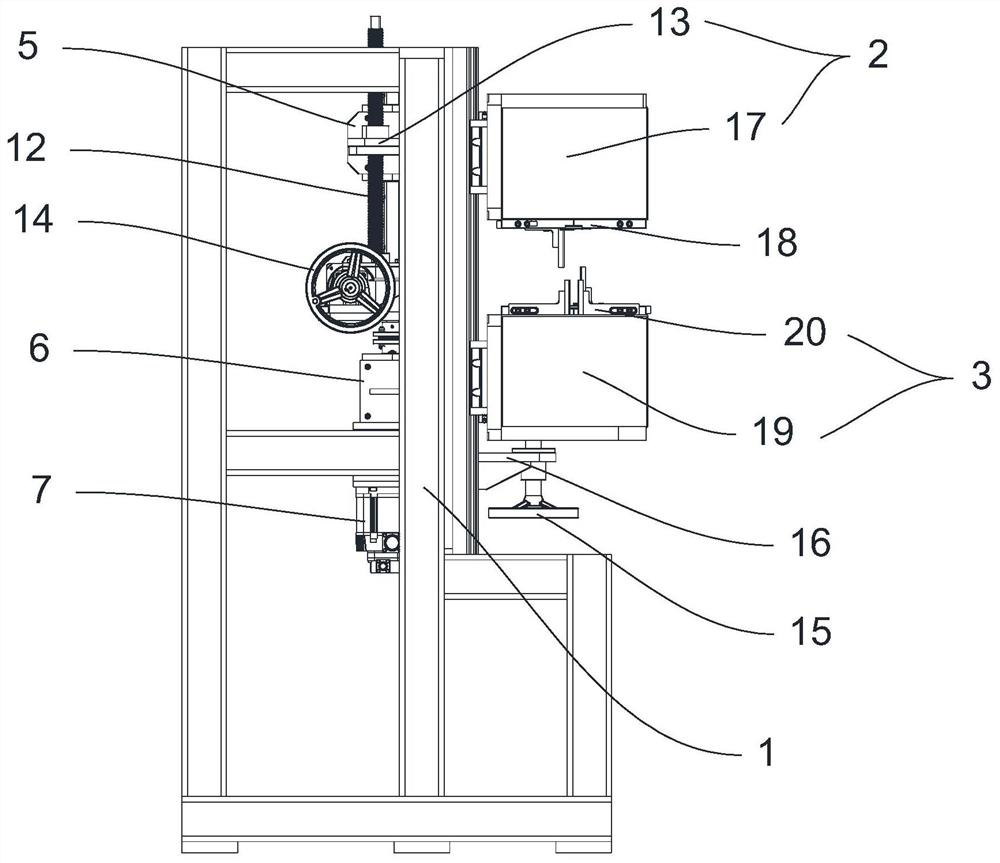

[0030] Please refer to Figure 1 to Figure 3 , the present embodiment provides transposition wire casting equipment, including a mounting frame 1, a first casting assembly 2 and a second casting assembly 3 cooperating with the above-mentioned first casting assembly 2, the above-mentioned first casting assembly 2 and the above-mentioned The second forming components 3 are all slidably connected to the above-mentioned mounting frame 1 .

[0031] In this embodiment: because the first molding assembly 2 and the second molding assembly 3 are all slidingly connected to the installation frame 1, so when in use, the first molding assembly 2 and the second molding assembly 3 are connected up and down, and the wires are sent to Insert between the first punching assembly 2 and the second punching assembly 3, wire is punched at the same time, and the transposition wire that punches is sent out between the first punching assembly 2 and the second punching assembly 3.

[0032] The first fo...

Embodiment 2

[0035] Please refer to Figure 1 to Figure 3 , this embodiment is based on Embodiment 1, and the difference from Embodiment 1 is that it also includes a transmission assembly 4, and the above transmission assembly 4 includes a first transmission member 5, a second transmission member 6 and a servo motor 7, and the above servo motor 7 , the second transmission member 6 , and the first transmission member 5 are connected in sequence, the first transmission member 5 is connected to the first forging assembly 2 , and the second transmission member 6 is connected to the second forging assembly 3 .

[0036] In this embodiment: the servo motor 7, the second transmission member 6, and the first transmission member 5 are connected sequentially, the first transmission member 5 is connected to the first forging assembly 2, the second transmission member 6 is connected to the second forging assembly 3, The servo motor 7 provides power, which is sequentially transmitted to the second trans...

Embodiment 3

[0039] Please refer to Figure 1 to Figure 3 , this embodiment is based on any of the above-mentioned embodiments, and the difference from any of the above-mentioned embodiments is that the above-mentioned first forging assembly 2 includes a third transmission part 17 and a first forging part 18, and the above-mentioned third transmission part 17 Connected to the first transmission member 5 , the first forging portion 18 is located at the bottom of the third transmission member 17 .

[0040]In this embodiment: the third transmission member 17 is drivingly connected to the first transmission member 5, the first forging part 18 is located at the bottom of the third transmission member 17, the first transmission member 5 drives the third transmission member 17 to work, the third The transmission member 17 drives the first forging part 18 to perform the forging work of the transposition wire.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap