Stamping type metal casting mold for railway locomotive vehicle accessories

A technology for metal casting and railway locomotives, applied in the field of stamping die casting devices, can solve the problems of no stamping protection mechanism, unable to change stamping stroke, constant stamping force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

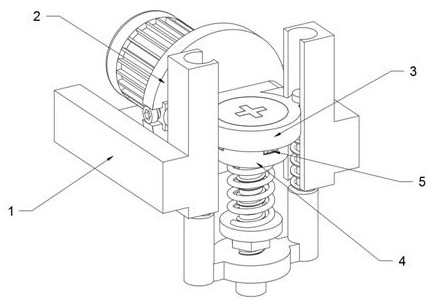

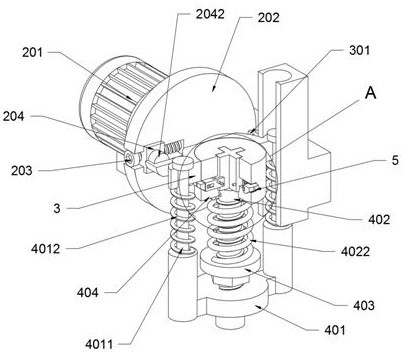

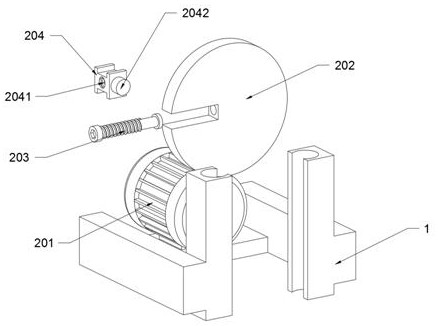

[0041] as attached figure 1 to attach Figure 9 Shown:

[0042] The invention provides a stamping type metal casting mold for railway locomotive vehicle parts, including a mounting bracket 1;

[0043] The installation bracket 1 is fixedly installed inside the casting device, and the top of the installation bracket 1 is equipped with a stamping reciprocating assembly 2;

[0044] The stamping reciprocating assembly 2 includes a drive motor 201, a drive disc 202, an adjustment rod 203 and a drive block 204. The drive motor 201 is fixedly mounted on the top of the mounting bracket 1, and the drive disc 202 is fixedly connected to one end of the rotating shaft of the drive motor 201. The adjustment rod One end of the rod body of 203 is rotatably connected to the inside of the disc body of the drive disc 202, and the drive block 204 is plugged in outside the rod body of the adjustment rod 203. When the device is in use, the stamping stroke of the bottom stamping column 401 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com