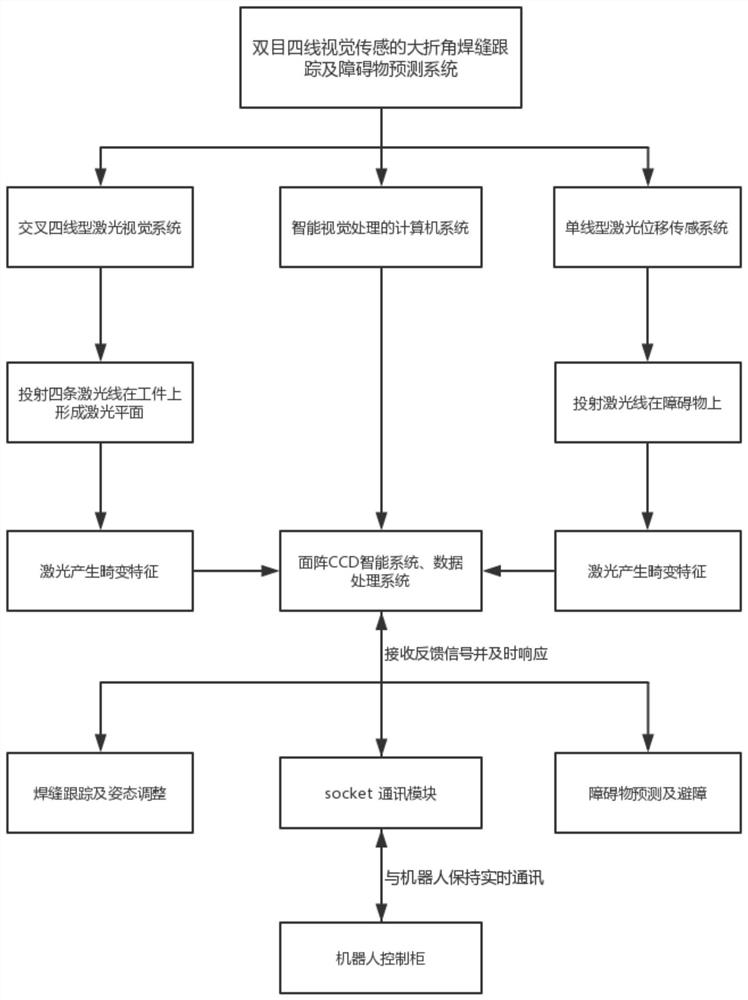

Large-break-angle welding seam tracking and obstacle prediction system based on binocular four-line vision sensing

A technology of visual sensing and prediction system, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problem of collision between welding torch and obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

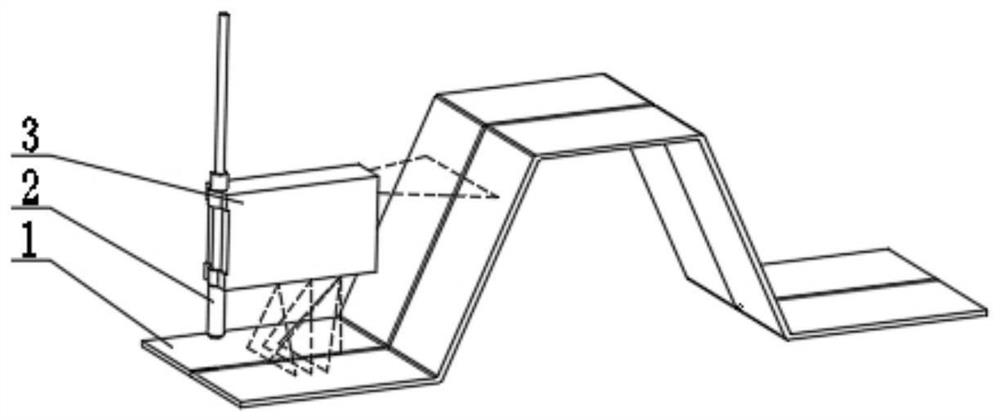

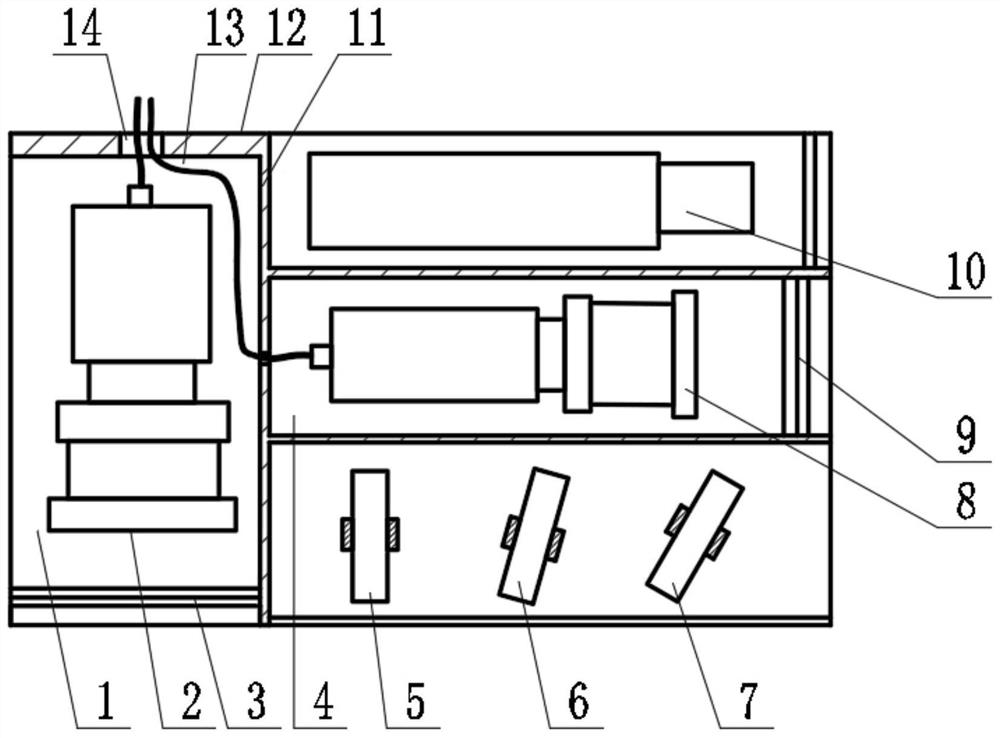

[0020] In order to better express the technical solutions and beneficial effects of the entire invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation cases. Embodiments of the present invention are not limited thereto.

[0021] First introduce the principle of triangulation ranging:

[0022] The laser triangulation method mainly uses a beam of laser light emitted by a laser to irradiate the measured target at a certain incident angle. The laser light is reflected and scattered on the target surface, and at another angle, it passes through the light reduction and filter system, and uses the lens to reflect the reflected laser light. Convergence imaging, spot imaging on the intelligent vision system of CCD. When the measured object moves along the laser direction, the light spot on the position sensor will move, and its displacement corresponds to the moving distance of the measured object. Thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com