Vehicle exit spraying decontamination device for building construction site

A construction and on-site technology, applied in the field of dust-proof cleaning of vehicles on construction sites, can solve problems such as inability to change vehicles of different sizes and models, flooding of flushing water, poor safety and stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

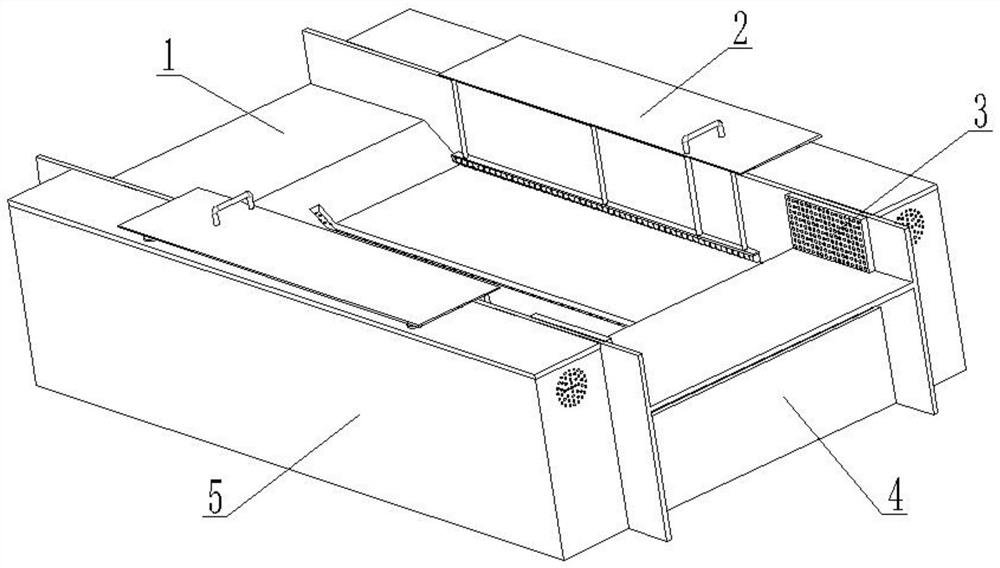

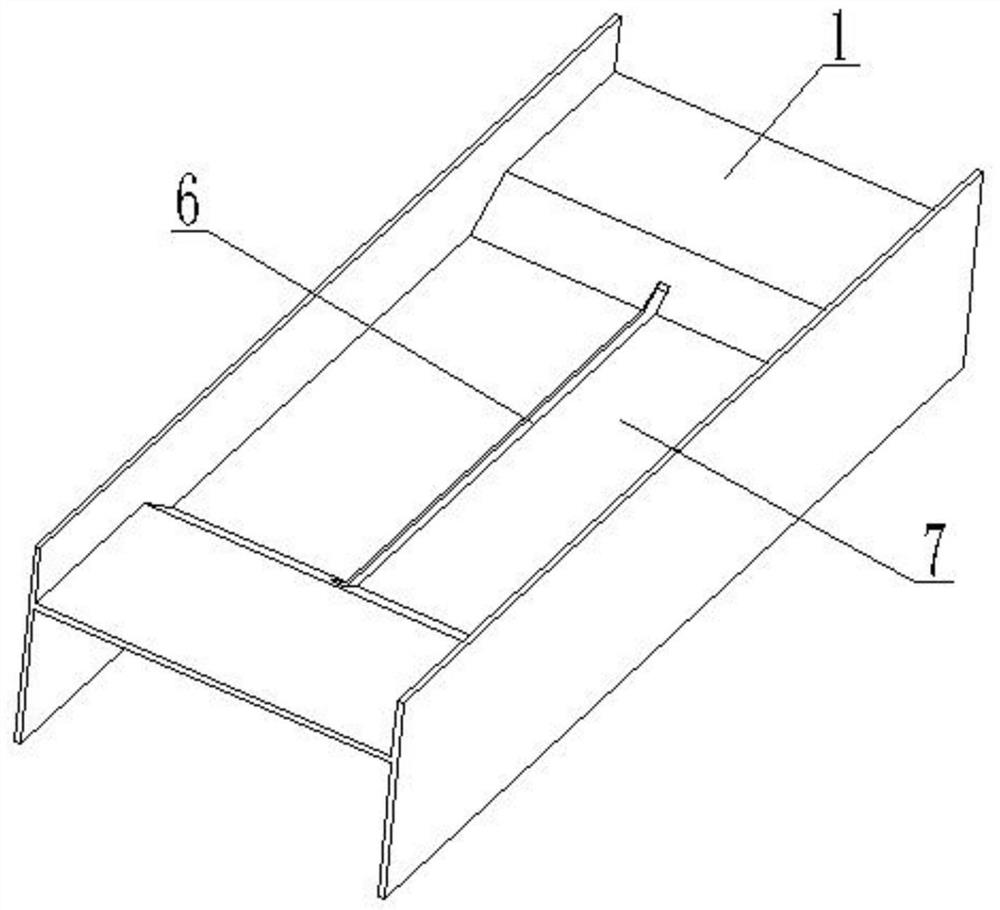

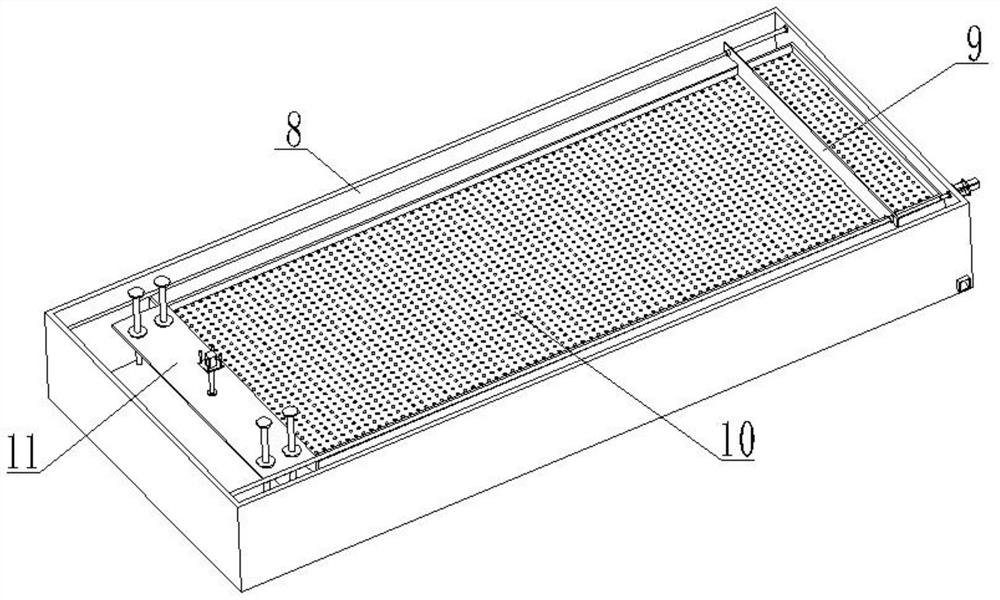

[0032] Example: see Figure 1-13, a vehicle exit spray decontamination device at a building construction site, comprising a spray decontamination platform 1, a side installation box 5, a lift sprinkler 2, a sewage processor 4 and an air dryer 3, and the spray decontamination platform 1 is made of a steel plate It is made by welding, with a T-shaped decontamination tank 7 in the middle, a gutter 6 in the middle of the decontamination tank 7, a set of side installation boxes 5 on both sides of the spray decontamination table 1, and the side installation boxes 5 are internally separated An air dryer installation chamber 43, a lifter installation chamber 44 and a water storage chamber 45 are formed. A number of air guide holes 42 are uniformly distributed on the side installation box 5 on one side of the air dryer installation chamber 43, and an air dryer is arranged in the air dryer installation chamber 43. 3. There are two sets of air dryers 3, which are symmetrically arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com