Particle material ship side-by-side lightering method

A technology for granular materials and ships, which is applied to ship accessories, barges/barges, cargo handling equipment, etc. It can solve the problems of high cost, bulky transfer platform, and unsuitable for transfer of granular bulk materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

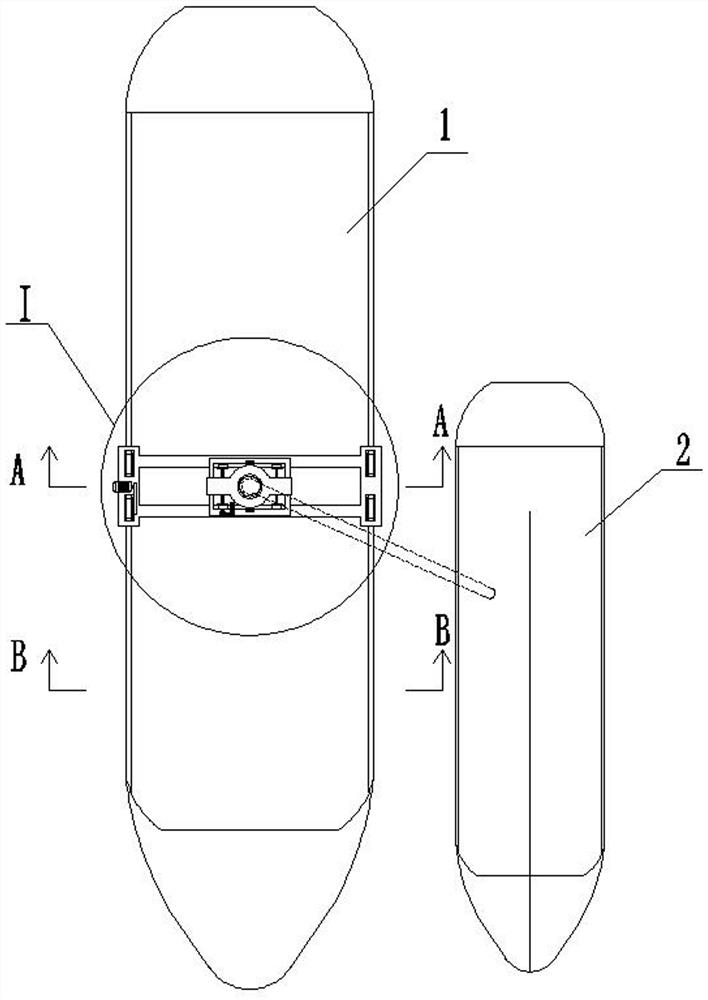

[0042] A particulate material ship is relying on the method, including the following steps:

[0043] (1) After the transportation boat is irradiated, the barge is parallel to the side of the transportation boat;

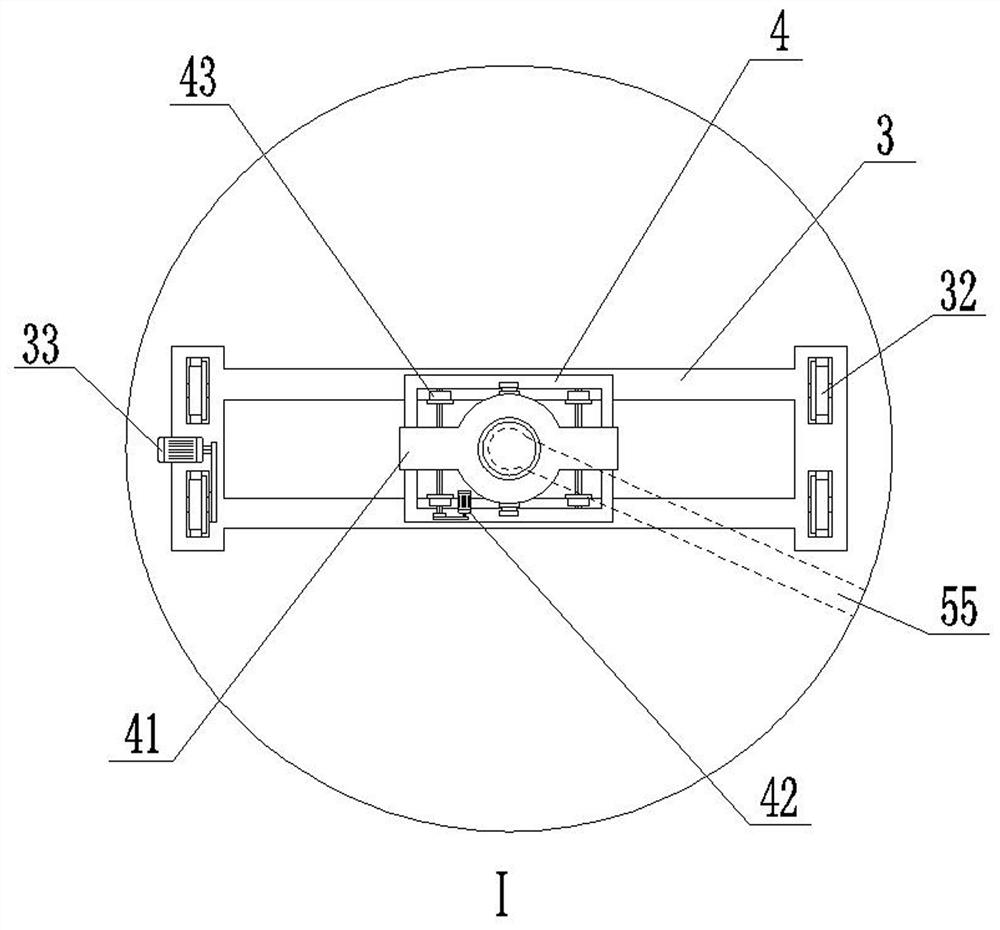

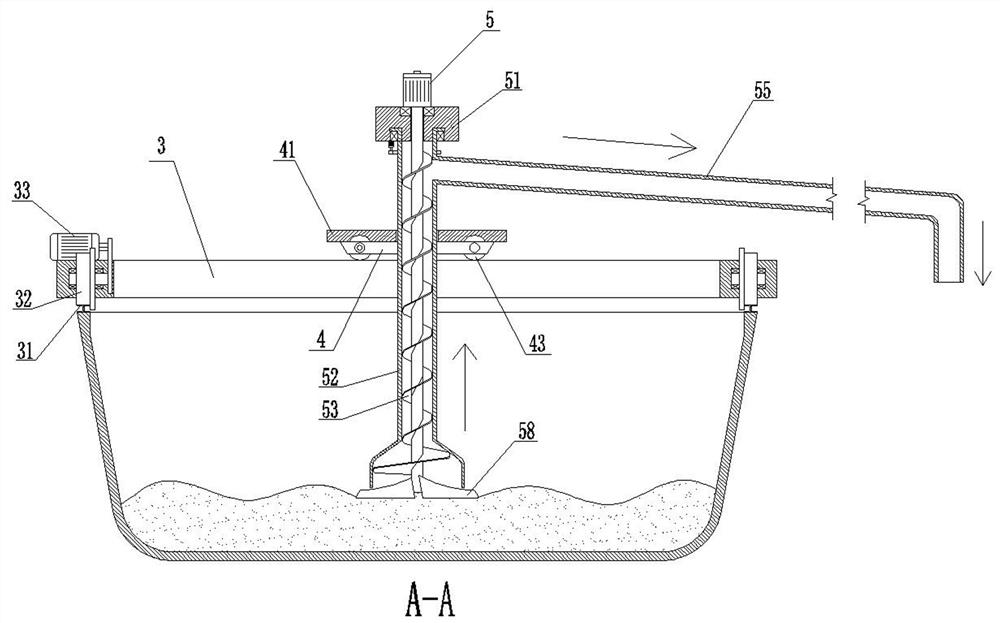

[0044] (2) Start the particulate material ship and rely on the transition system, start the rotary electric machine, turn the end of the lateral feed tube out, export the ware of the barge;

[0045] (3) Start the transfer motor, the twinkle will continue to deliver the particulate material source in the transport shipping tube to the transverse feed tube until the ware of the barge;

[0046] (4) Communication and transverse trains, plus the lifting operation of the hydraulic cylinder, walk vertex to the cabin to the barge;

[0047] (5) Start the rotating motor to recover the end of the transverse feed tube to the position of the transportation boat, complete the finite work.

[0048] Particle material ships rely on the transition system, the barge 2 is on the side of 5,0...

Embodiment 2

[0059] Different from Example 1 Differentially: Longitudinal Walking Truck 3, Transmission Car 4, Rotating Motors 56 and Turning Motors 5 Follow the automatic runs of automatic walking to each position of the cabin, thereby completing the inhalation conveying of all materials of the cabin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com