Gear shot blasting device for high-end equipment manufacturing

A shot blasting device and equipment technology, applied in the direction of improving process efficiency, etc., can solve problems such as waste, complicated process, and low efficiency of gear shot peening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

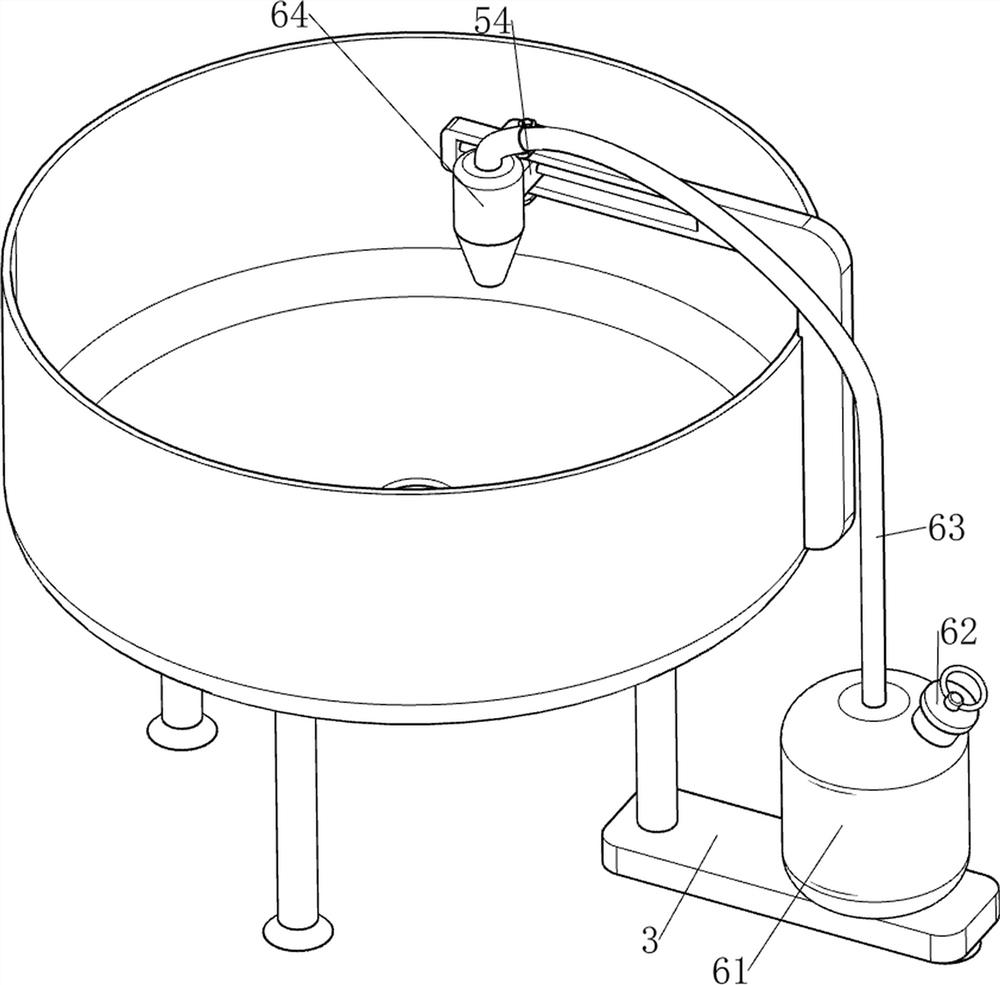

[0027] A gear shot peening device for high-end equipment manufacturing, such as figure 1 As shown, it includes a support column 1, a protective frame 2, a support plate 3, a clamping assembly 4, a sliding assembly 5, and a shot peening assembly 6. The top of the support column 1 is connected with a protective frame 2, and the right side of the support column 1 is fixed There is a support plate 3, and the middle part of the protective frame 2 is provided with a clamping assembly 4 in a rotating manner. The outer wall of the protective frame 2 is equipped with a sliding assembly 5. The sliding assembly 5 is located above the protective frame 2. The sliding assembly 5 and the supporting plate 3 are equipped with spray Pill Component6.

[0028] When the worker needs to shot peen the gear, the worker first needs to pull the clamping assembly 4 to the outside, the clamping assembly 4 is compressed, and when the clamping assembly 4 moves to the outside to a position large enough, the...

Embodiment 2

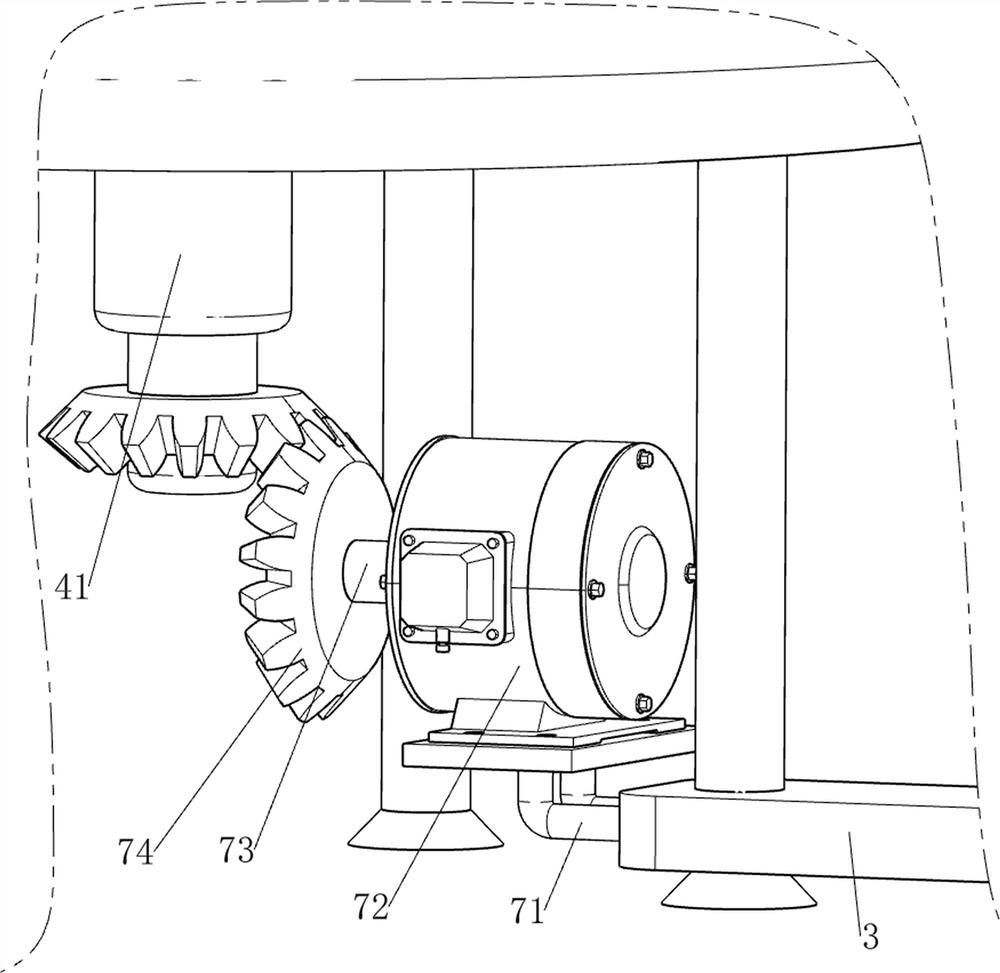

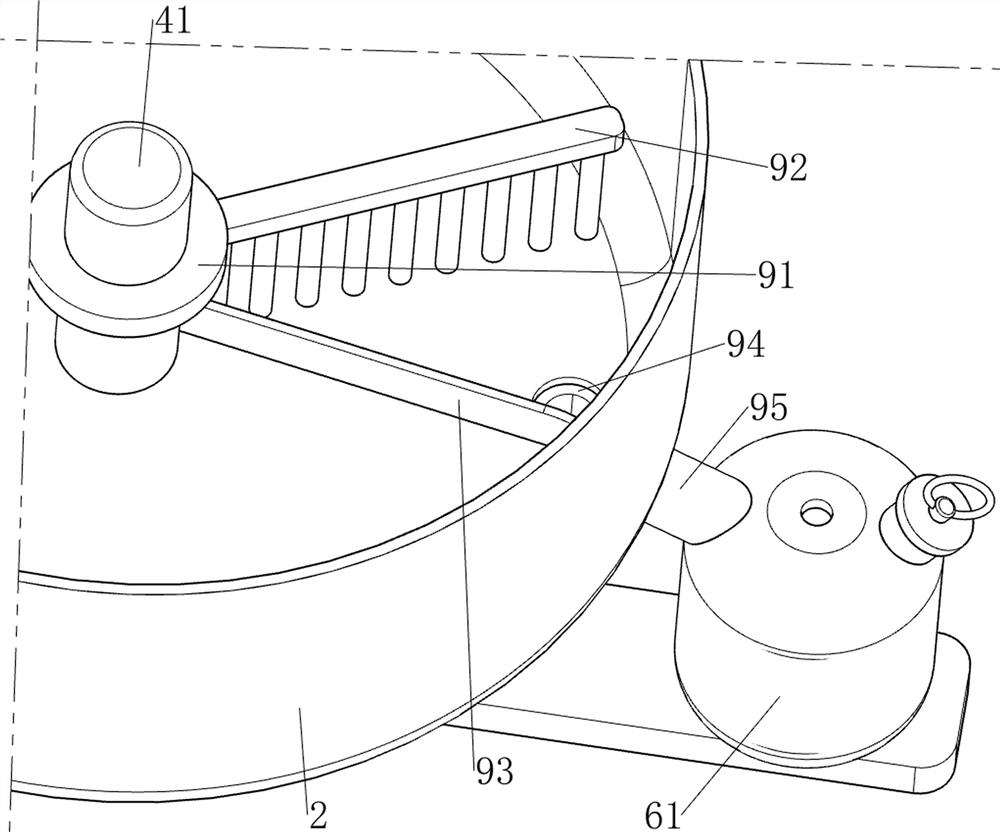

[0030] In a preferred embodiment of the present invention, as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the clamping assembly 4 includes a first rotating shaft 41, a turntable 42, a guide rod 44, a first slider 45, a first spring 46 and a clamping rod 47, and the middle part of the protective frame 2 is provided with a first rotating shaft 41 for rotation. , the first rotating shaft 41 is fixedly connected with a turntable 42, and the top of the turntable 42 is spaced with a first chute 43, the number of the first chute 43 is six, and a guide rod 44 is connected between the six first chute 43, The number of guide rods 44 is six, and the six guide rods 44 are all slidably provided with a first slide block 45, and the six guide rods 44 are equipped with a first spring 46, and the two ends of the first spring 46 are respectively connected to the rotating disk 42 and On the first sliders 45 , the tops of the six first sliders 45 are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com