Thread trimming structure and automatic thread trimming and presser foot lifting integrated zigzag sewing machine

A technology of lifting presser foot and sewing machine, applied in the field of sewing machine, can solve the problems of large moving space of the tool, increasing the cutting range, and unable to cut the suture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

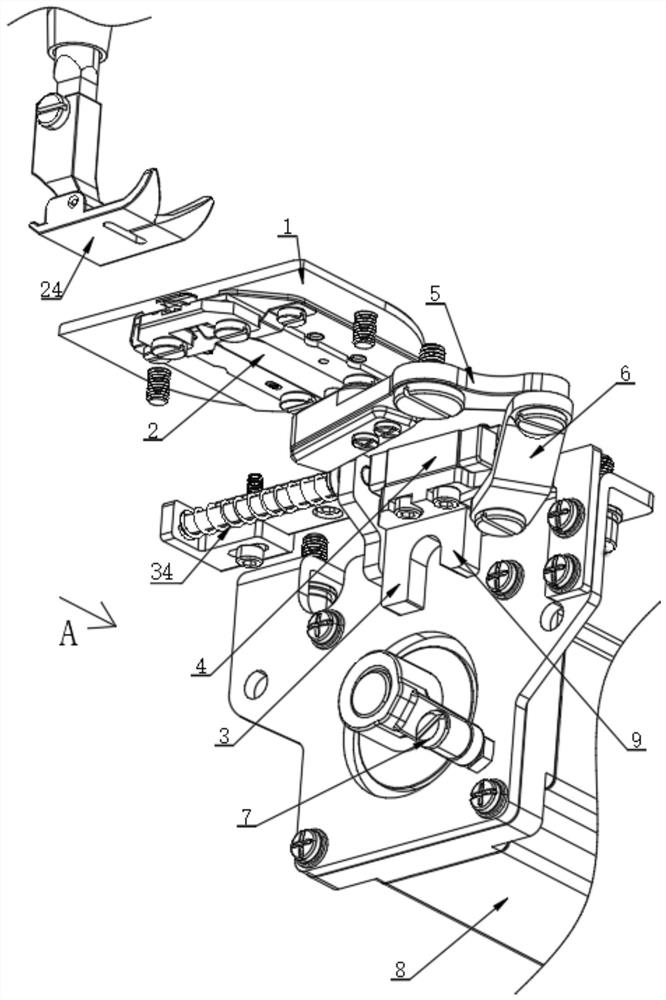

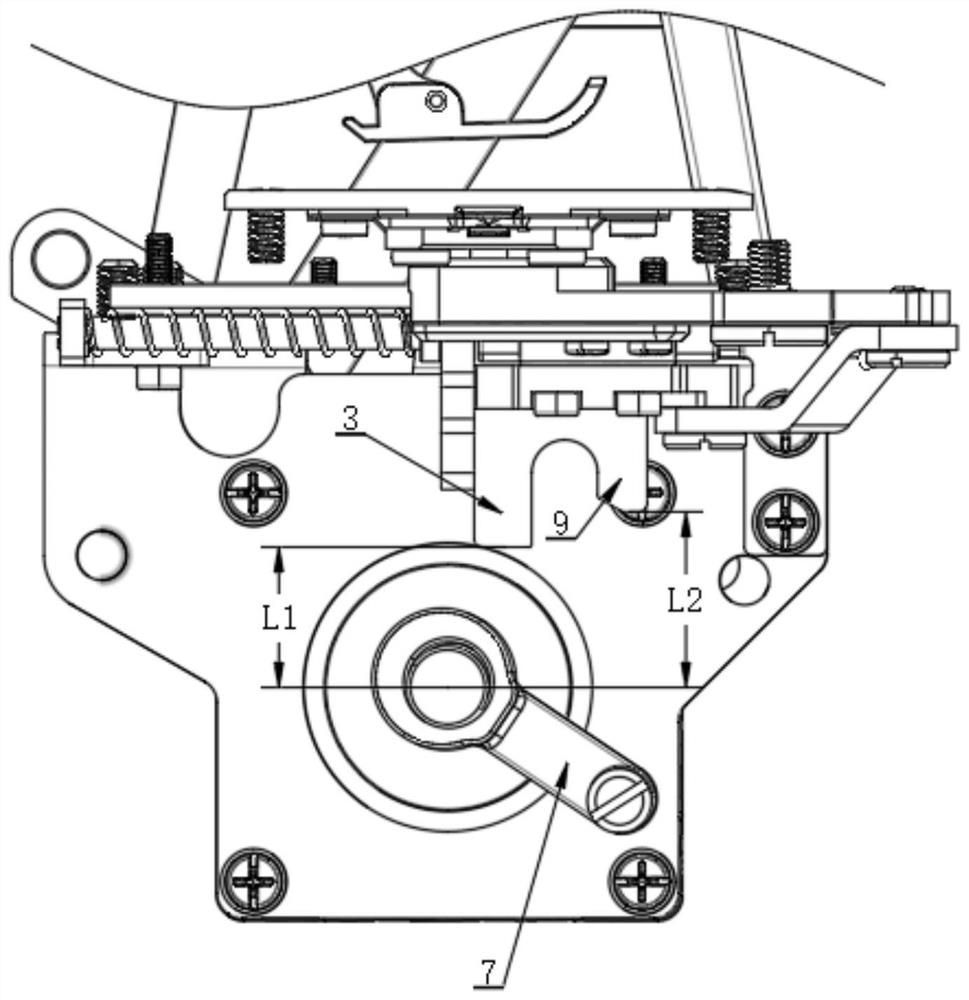

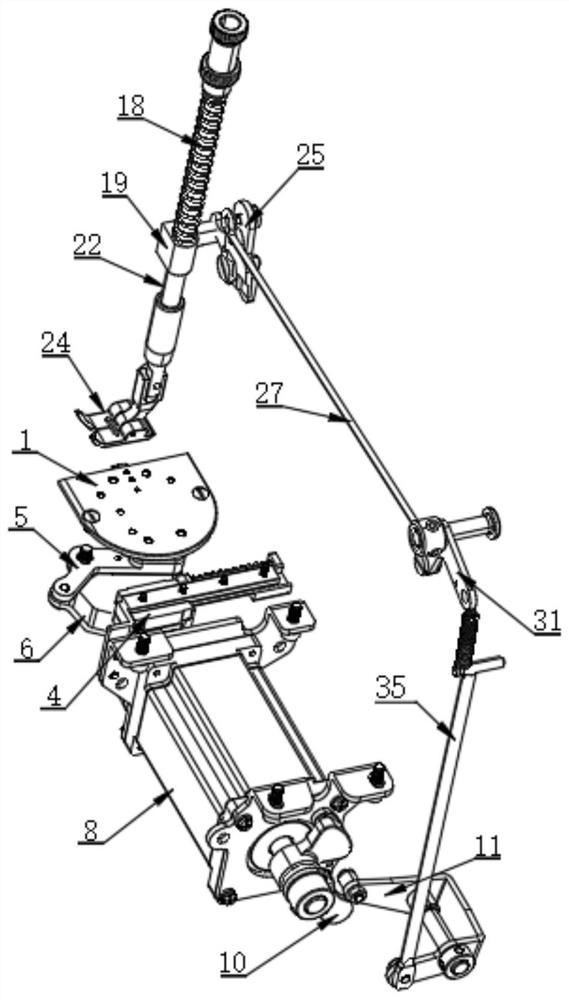

[0025] refer to Figure 1 to Figure 4 As shown, this embodiment provides a thread trimming structure and a zigzag sewing machine with automatic thread trimmer and presser foot lifter, including a thread trimming structure, the thread trimming structure includes a stepping motor assembly 8 and a cam mechanism, and the stepping motor The action of the assembly 8 is controlled by the control box. The cam mechanism is driven by the stepper motor assembly 8 to rotate. The cam mechanism includes a thread trimmer crank 7 and a lift crank 10. The stepper motor assembly 8 is a double output shaft motor, the thread trimming crank 7 and the lifting crank 10 are respectively sleeved on the output shafts on both sides of the stepping motor assembly 8, and the forward and reverse rotation of the stepping motor assembly 8 is controlled by the control box , to control the forward rotation and reverse rotation of the thread trimming crank 7 and the lifting crank 10.

[0026] The thread trimmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com