A long-term stainless steel pipe sealing joint

A stainless steel pipe and sealing joint technology, applied in the field of pipe joints, can solve the problems of low installation efficiency, easy cracking and aging, and high maintenance frequency, and achieve the effect of protecting from damage, prolonging sealing aging, and improving sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

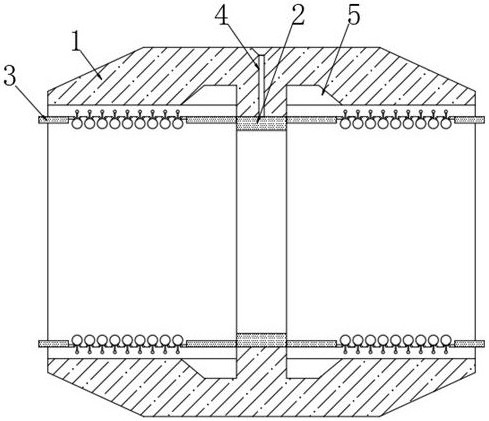

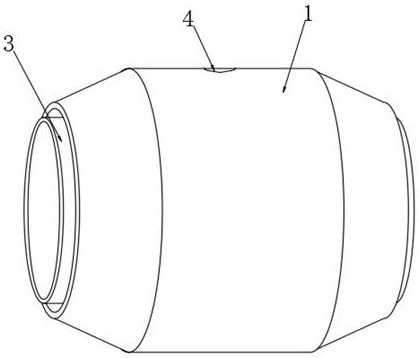

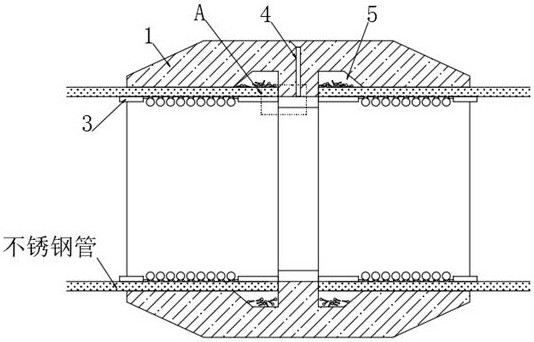

[0049] see Figure 1-2 , a long-term stainless steel pipe sealing joint, including a joint body 1, the center of the joint body 1 presents an inwardly convex structure, and an inner ring 2 is fixedly connected to the protrusion on the inner wall of the joint body 1, and the inner ring 2 has two left and right sides. The outer end is inserted with a pre-sealed undulating pipe 3, the upper end of the joint body 1 is drilled with a liquid injection port 4, and both sides of the protrusion on the inner wall of the joint body 1 are provided with a pre-storage ring groove 5, and the pre-storage ring groove 5 is excavated in the joint body 1 The inner wall, and the cross-section of the pre-storage ring groove 5 is a trapezoidal structure. During installation, when guided by a magnet, the pre-storage ring groove 5 provides a certain accommodation space for the broken pre-breaking magnetic rod, so that it is not easy to affect the movement of the stainless steel pipe to the joint body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com