Commercial kitchen oil fume purifier

A lampblack purifier and kitchen technology, which is applied in the direction of removing lampblack, applications, household stoves, etc., can solve the problems of slowing down of cleaning work efficiency, clogging of lampblack, and reducing the dust filtering effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

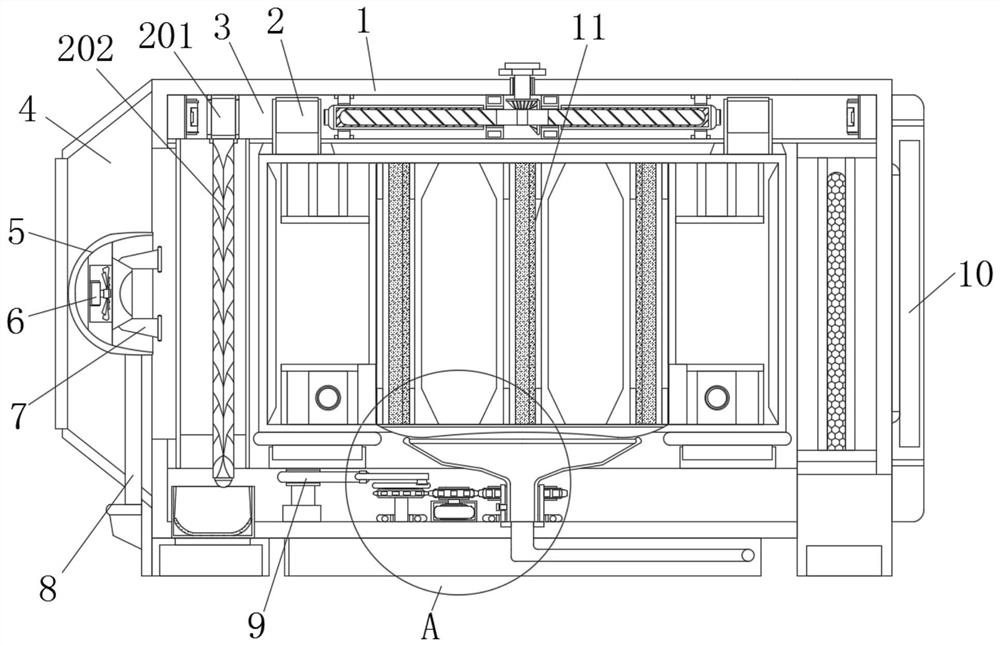

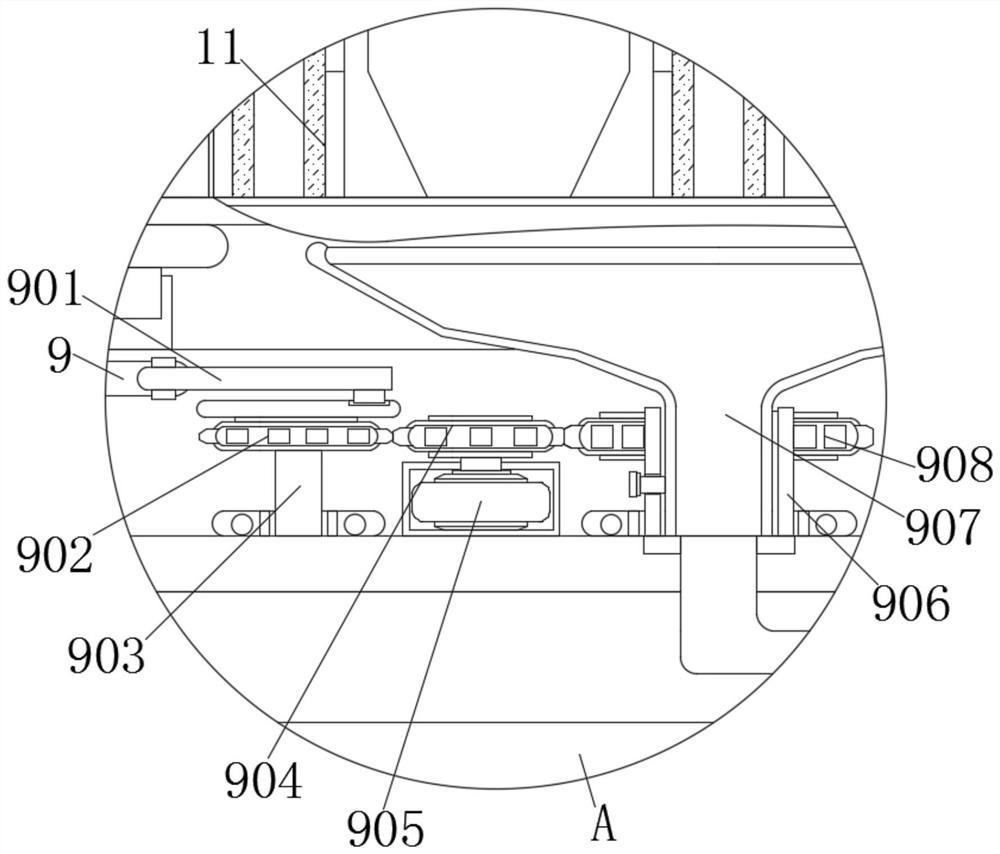

[0038] Example 1, such as Figure 1-3 As shown, when the flue gas passes through the filter screen plate 202 for filtering, the driving motor 905 can be started through the control box 12 to drive the driving gear 904 to rotate, and the driving gear 904 will mesh with the qualified tooth disc 908 of the driven gear 902 respectively with the rotation of the driving gear 904 , with the rotation of the driven gear 902 to drive the rotating rod 903 and the turntable 909 to rotate, the rotation of the turntable 909 drives the movable hinge plate 901 and the striker rod 9 to interact with each other, so that the striker rod 9 is formed intermittently under the movement of the hinge plate 901 The impact structure can continuously impact the bottom of the filter screen plate 202, shake off the dust filtered on the surface of the filter screen plate 202 and collect it in the ash accumulation tank, which is convenient for subsequent cleaning work, and the rotation of the tooth plate 908 ...

Embodiment 2

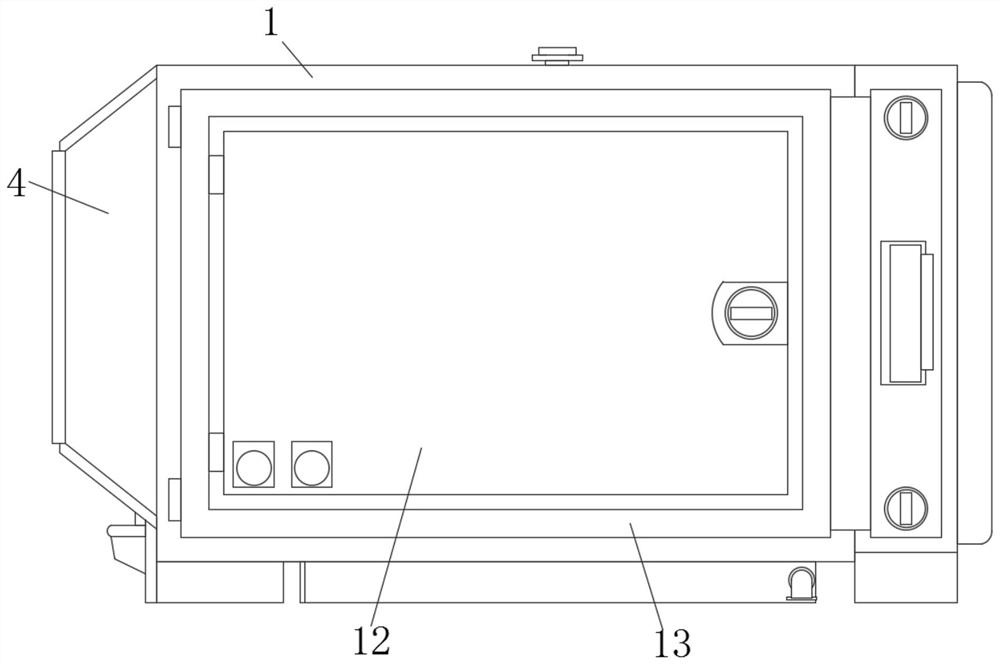

[0039] Example 2, such as figure 1 with Figure 4 As shown, when it is necessary to disassemble and clean the filter screen plate 202 or the high and low voltage electrostatic field 11, the operator can directly rotate the handle 208 outside the device to drive the first bevel gear 204 to rotate, so that the first bevel gear 204 and the second bevel gear The gears 205 mesh with each other, forcing the second bevel gear 205 to drive the two-way screw rod 206 to rotate. With the rotation of the two-way screw rod 206, the two sets of internally threaded pipes 203 shrink inwardly under the cooperation of the limit collar, thereby making the internally threaded pipes 203 gradually passes through the inside of the inserting block 201 and the two sets of positioning blocks 2, cancels the insertion and fixing of the inserting block 201 and the positioning block 2, and impels the filter plate 202 and the high and low voltage electrostatic field 11 to be taken out for cleaning Or maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com