Array substrate, manufacturing method and display panel

A technology of an array substrate and a manufacturing method, which can be applied to instruments, nonlinear optics, optics, etc., and can solve problems such as depolarization of display panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

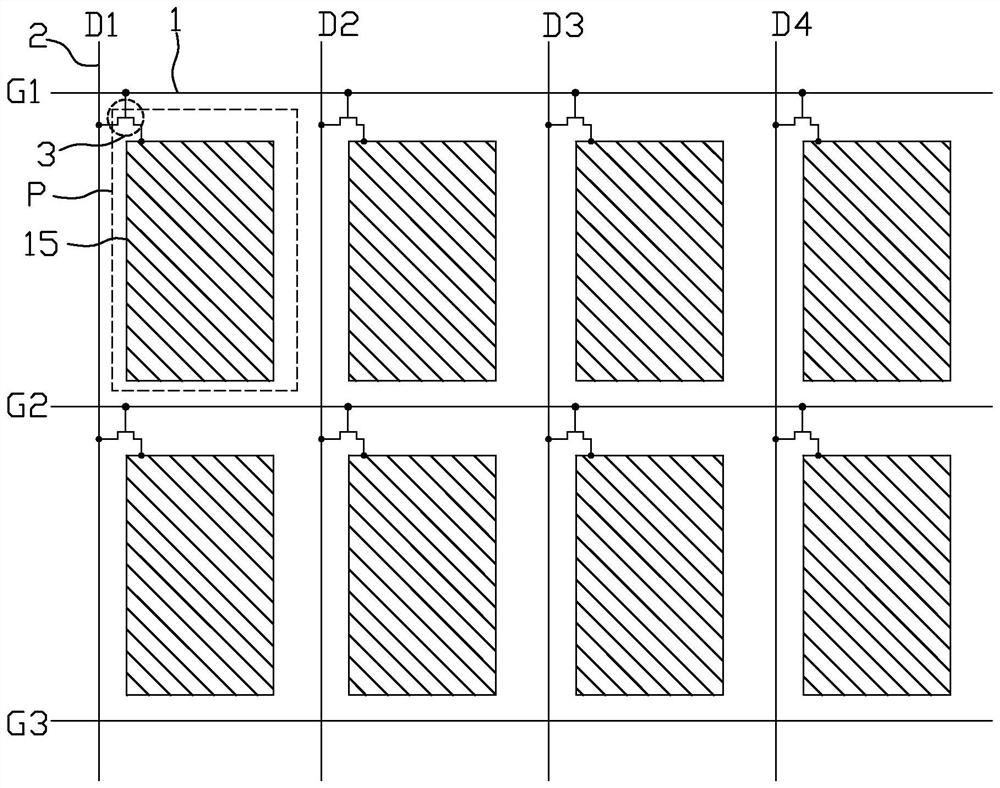

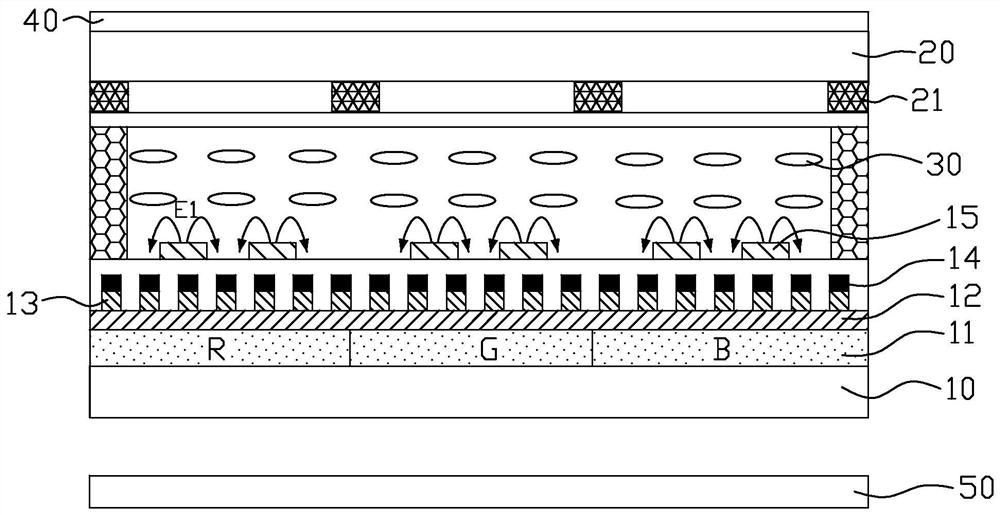

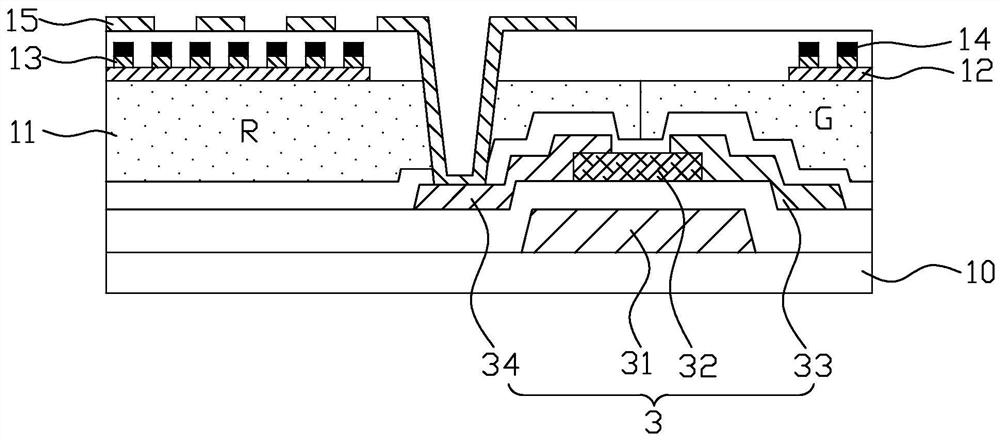

[0059] figure 1 is a schematic plan view of the array substrate in the present invention, figure 2 is a schematic cross-sectional structure diagram of the display panel in Embodiment 1 of the present invention, image 3 is a schematic cross-sectional view of the array substrate at the thin film transistor in Embodiment 1 of the present invention.

[0060] Such as Figure 1 to Figure 3 As shown, an array substrate provided by Embodiment 1 of the present invention includes a substrate 10 and scan lines 1 , data lines 2 , thin film transistors 3 and pixel electrodes 15 disposed on the substrate 10 . A plurality of pixel units P are formed on the substrate 10 by a plurality of scanning lines 1 and a plurality of data lines 2 insulated from each other and intersecting each other. Each pixel unit P is provided with a thin film transistor 3 and a pixel electrode 15, and each pixel electrode 15 passes through an adjacent pixel. The thin film transistor 3 of the electrode 15 is ele...

Embodiment 2

[0084] Figure 5 is a schematic cross-sectional view of the array substrate at the thin film transistor in Embodiment 2 of the present invention. Such as Figure 5 As shown, the array substrate, the manufacturing method and the display panel provided by Embodiment 2 of the present invention are the same as Embodiment 1 ( figure 1 The array substrate and the manufacturing method in FIG. 4) are basically the same as the display panel, except that, in this embodiment, the pixel electrode 15 is arranged on the surface of the quantum dot layer 11 away from the substrate 10 and is connected to the quantum dot layer. The layer 11 is in direct contact, the metal wire grid polarizer 13 is arranged on the side surface of the pixel electrode 15 away from the substrate 10 and is in direct contact with the pixel electrode 15, and the common electrode 12 is arranged on the side of the metal wire grid polarizer 13 away from the pixel electrode 15 . That is, in this embodiment, the common ...

Embodiment 3

[0101] Image 6 is a schematic cross-sectional structure diagram of the display panel in Embodiment 3 of the present invention, Figure 7 is a schematic cross-sectional view of the array substrate at the thin film transistor in Embodiment 3 of the present invention, Figures 8a-8f It is a schematic diagram of the manufacturing process of the manufacturing method of the array substrate in the third embodiment of the present invention. Such as Image 6 - As shown in FIG. 8, the array substrate, the manufacturing method and the display panel provided by Embodiment 3 of the present invention are the same as Embodiment 1 ( figure 1 The array substrate and the manufacturing method in FIG. 4) are basically the same as the display panel. The difference is that, in this embodiment, the quantum dot layer 11 is arranged on the surface of the substrate 10 and is in direct contact with the substrate 10. The scanning lines 1, The data line 2 and the thin film transistor 3 are disposed on a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com