High-current automatic power-off protection mechanism

A technology of automatic power-off and protection mechanism, applied in protection switches, emergency protection devices, parts of protection switches, etc., can solve the problems of affecting the use of power-off protectors, troublesome fixing and removing wires, inconvenient to install and remove wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

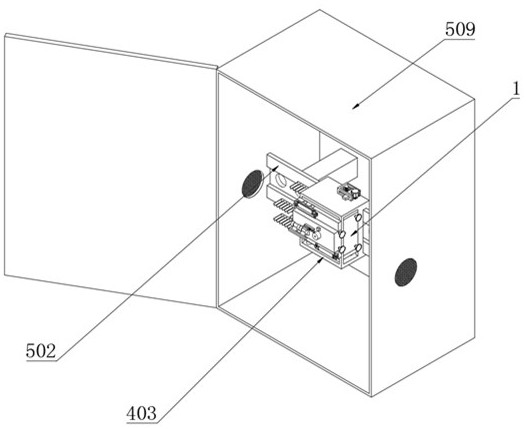

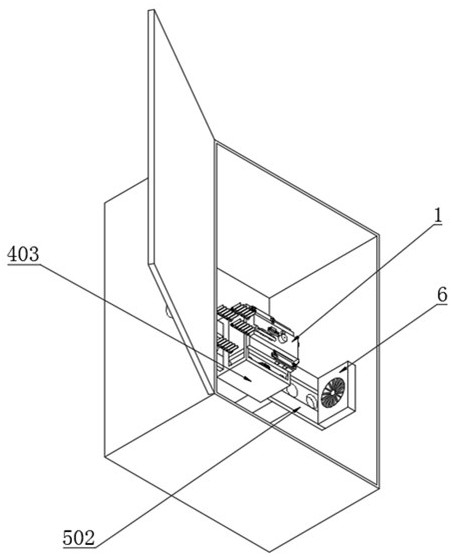

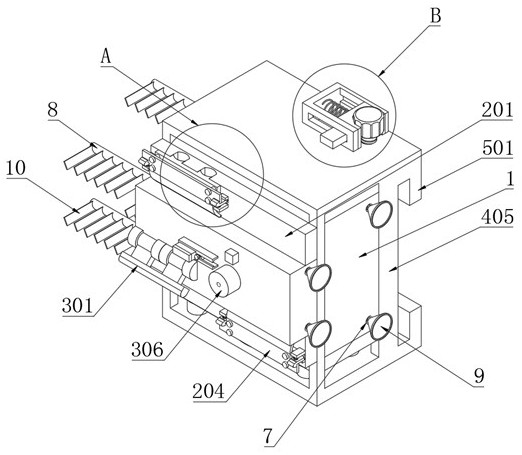

[0045] Example: such as Figure 1-9 As shown, the utility model provides a technical solution, a large current automatic power-off protection mechanism, including a power-off protector 1, a mounting assembly 2 is installed on the front of the power-off protector 1, and the mounting assembly 2 includes a plug-in board 201, Plug-in hole 202, crimping slot 203, crimping plate 204, extruding spring 205, extruding plate 206, movable rod 207, spring block 208, crimping block 209, limiter block 210, crimping bar 211, support plate 212 and locking spring 213, power-off protector 1 front top and bottom are symmetrically installed with plug-in board 201, plug-in board 201 front side is provided with two plug-in holes 202, plug-in board 201 side There is a crimping groove 203 at the position close to the power plug hole 202, and the end of the plug-in board 201 away from the crimping groove 203 is rotatably connected with a crimping plate 204, and a crimping plate 206 is placed on the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com