High-voltage-resistant low-temperature lithium ion electrolyte

An electrolyte, voltage-type technology, applied in the field of electrochemical energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

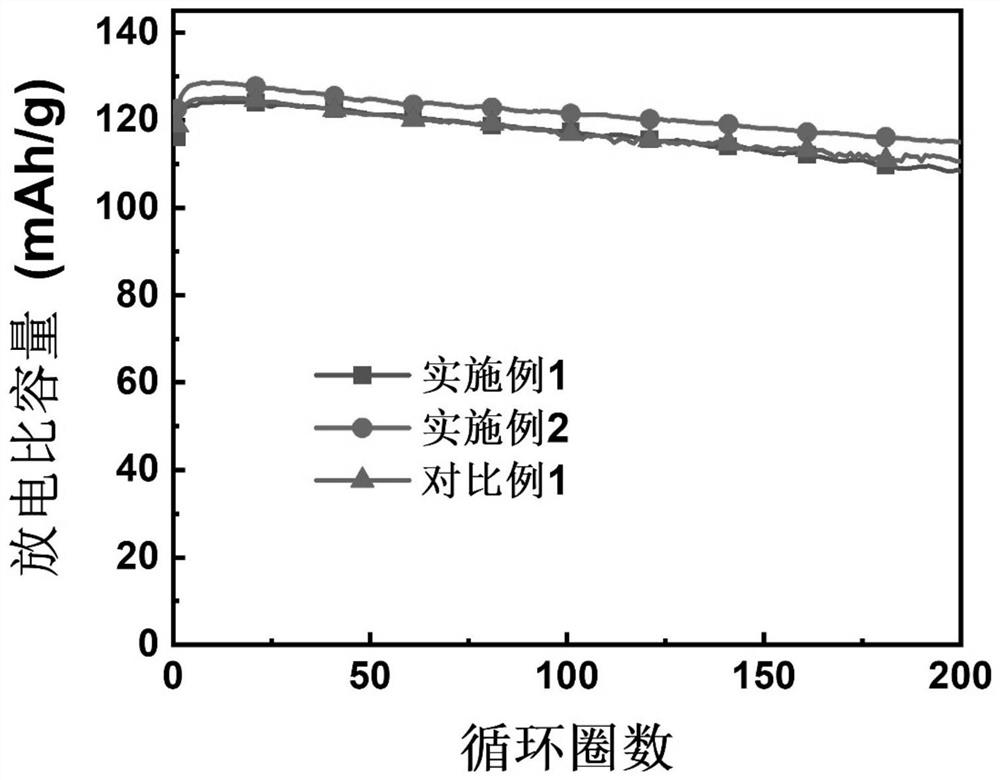

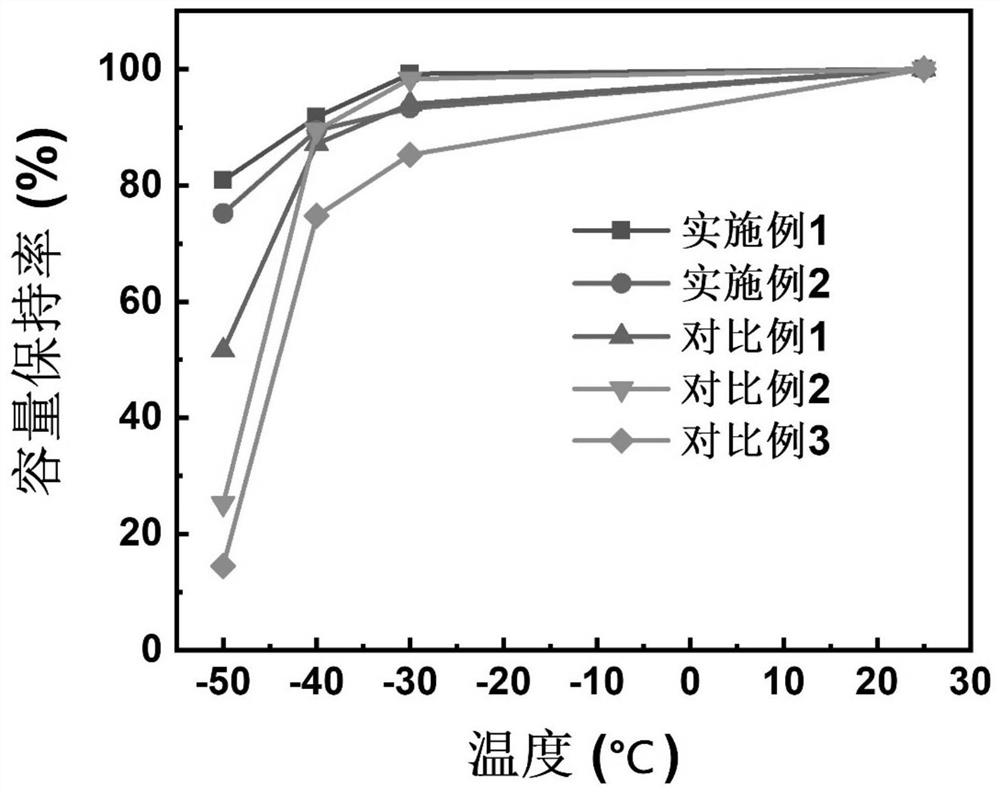

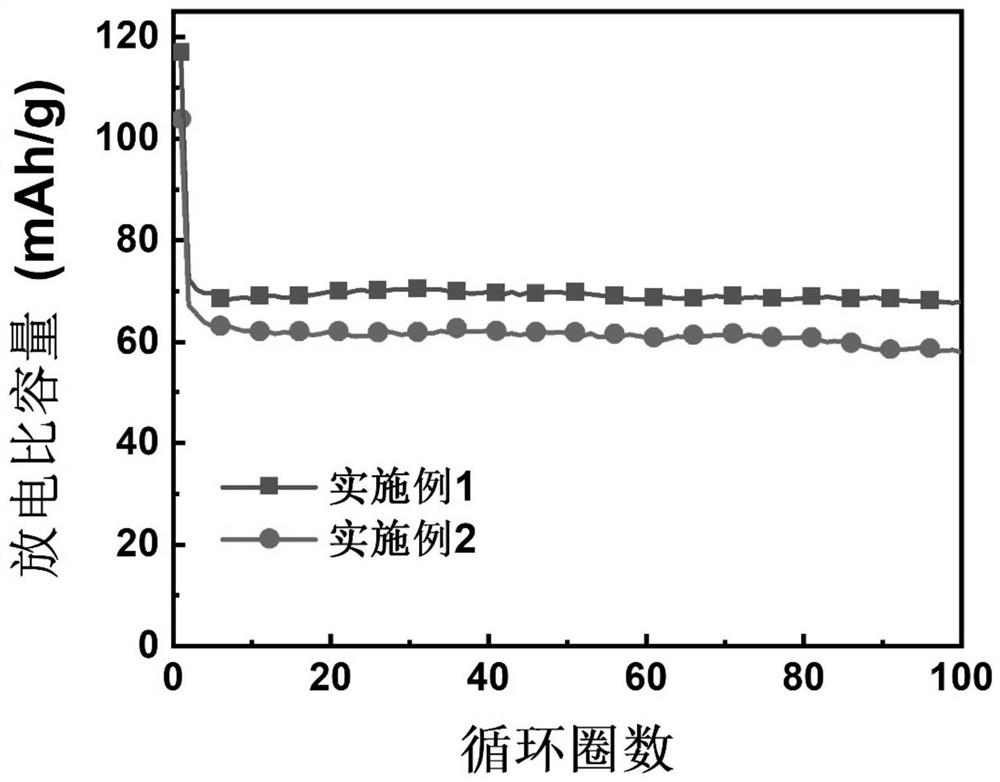

Embodiment 1

[0026] Add 0.450g of lithium tetrafluoroborate to 1.104g of methyl acetate, and mix well to obtain a high-concentration electrolyte; then add 0.436g of fluoroethylene carbonate to the high-concentration electrolyte, mix well, and add 1.941g of 1,1,2,2-tetrafluoroethyl methyl ether, fully stirred, mixed evenly, and filtered to obtain a high-voltage-resistant low-temperature lithium-ion electrolyte.

Embodiment 2

[0028] Add 0.450g of lithium tetrafluoroborate to 1.210g of ethyl methyl carbonate, and mix well to obtain a high-concentration electrolyte; then add 0.436g of fluoroethylene carbonate to the high-concentration electrolyte, and mix well, Add 1.941g of 1,1,2,2-tetrafluoroethyl methyl ether, fully stir, mix evenly, and filter to obtain a high-voltage-resistant low-temperature lithium-ion electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com