Self-adaptive damping spacer

A spacer, adaptive technology used in the installation of devices, electrical components, cables, etc. to maintain the spacing of parallel conductors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

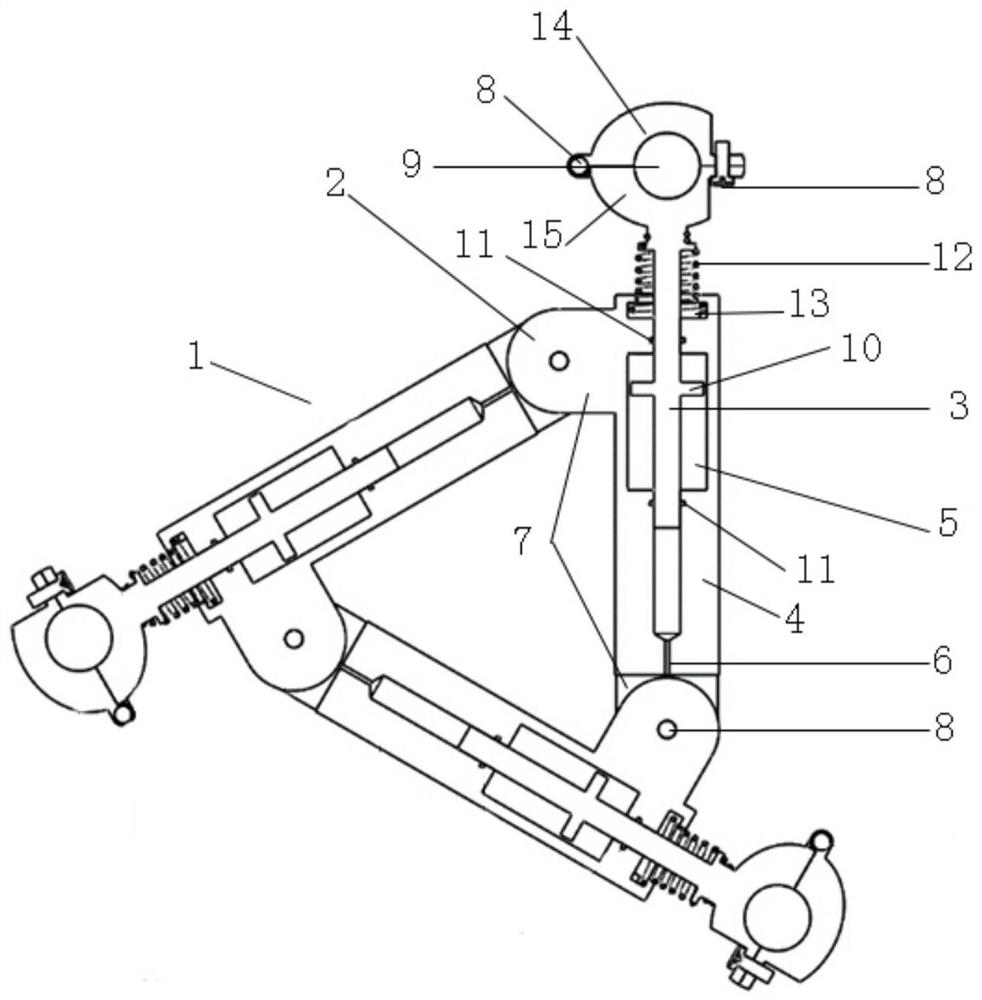

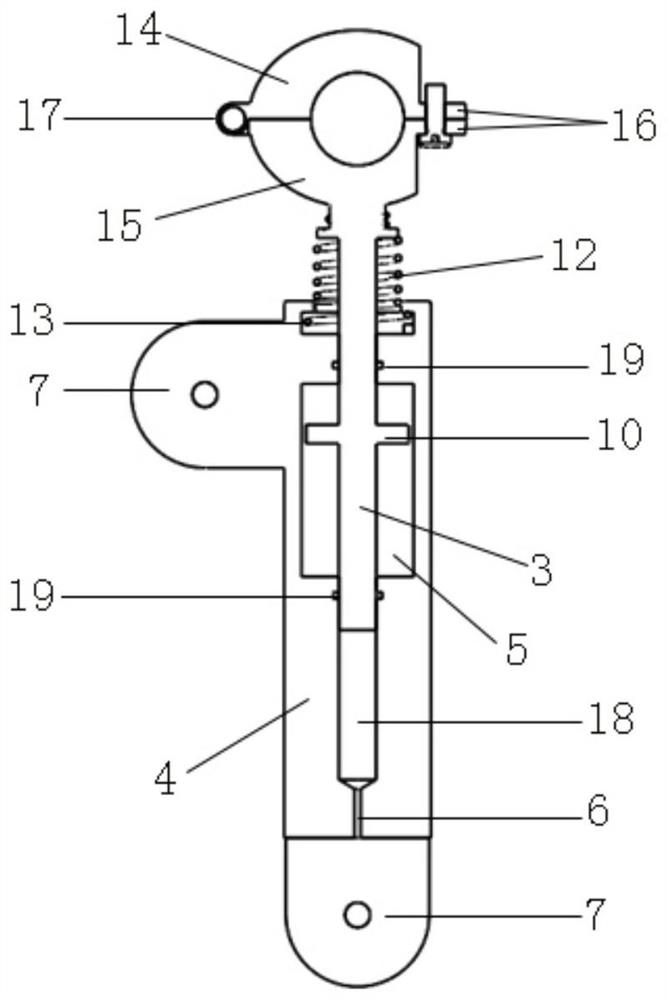

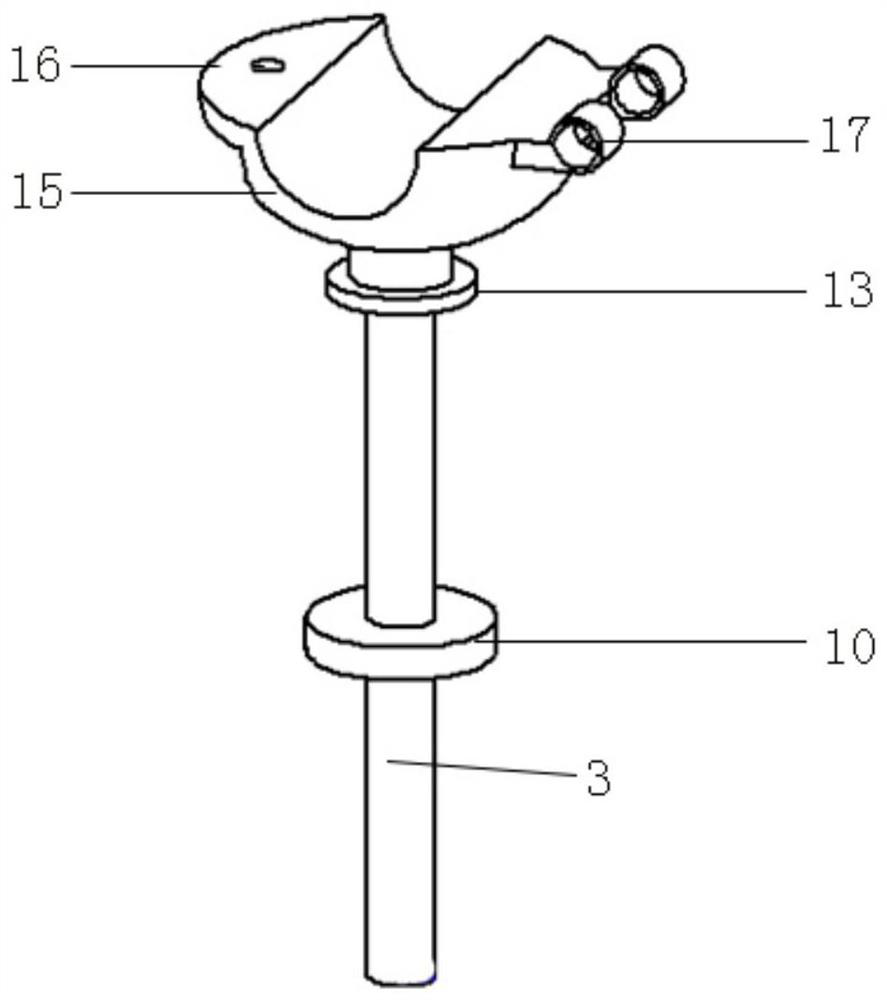

[0031] Such as Figure 1-Figure 4 As shown, an adaptive damping spacer includes a spacer body 1, and the spacer body 1 includes a plurality of damping cavities 2, which are connected to each other to form a triangular structure, which has the effect of preventing spin, and each damping cavity 2 Both include a pipe body 4 and a piston rod assembly, the piston rod assembly can move up and down along the axis of the pipe body 4 in the pipe body 4, including a piston rod 3, a wire clip 9, a spring clamp 13, a piston 10 and a sealing ring 11, The wire clamp 9 is arranged above the piston rod 3 for clamping the power transmission wire, and the spring clamp 13 is arranged on the piston rod 3 and below the wire clamp 9, and a reset is provided between the wire clamp 9 and the spring clamp 13. The spring 12 is used for the piston rod 3 to be pulled out when the external force is applied, and reset after the external force disappears. The piston 10 is arranged in the middle of the pisto...

Embodiment 2

[0041] The difference from Embodiment 1 is that different output damping forces can be provided by changing the structural dimensions of the inner cavity 5 and the piston 10 of the tube.

Embodiment 3

[0043] The difference from Example 1 is that by changing the ratio of the shear thickening liquid and using different raw materials to prepare the shear thickening liquid, it has different characteristics, has huge energy dissipation and absorption potential, and can provide greater Output damping force.

[0044] In the present invention, a cavity and a pressure balance hole are provided inside the pipe body, and the size of the piston is set smaller than the inner diameter of the pipe body cavity, so that an annular gap is formed between the piston and the pipe body cavity. When the wire vibrates under the action of external wind load At this time, under the action of external vibration load, the bottom of the piston rod is pushed into the cavity, and the shear thickening fluid in the chamber above the piston in the cavity enters the chamber below the piston through the annular gap, and the shear thickening fluid is flowing During the process, the shear rate of the shear thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com