Method for improving welding reliability of surface-mount type diverter

A shunt and SMD technology, applied in the field of improving the welding of SMD shunts, can solve the problem of unstable bubble rate, etc., and achieve the improvement of the bubble rate problem, the promotion of the reliability of the whole vehicle, and the optimization of the opening shape of the steel mesh. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

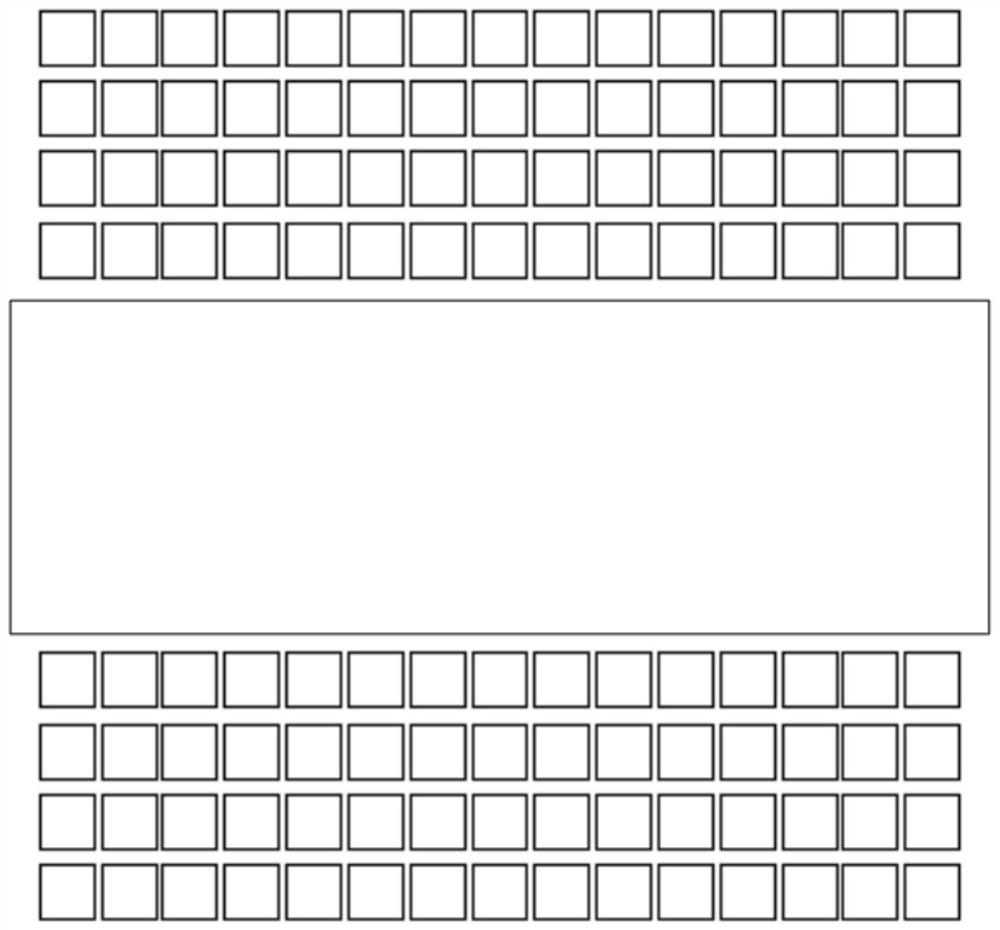

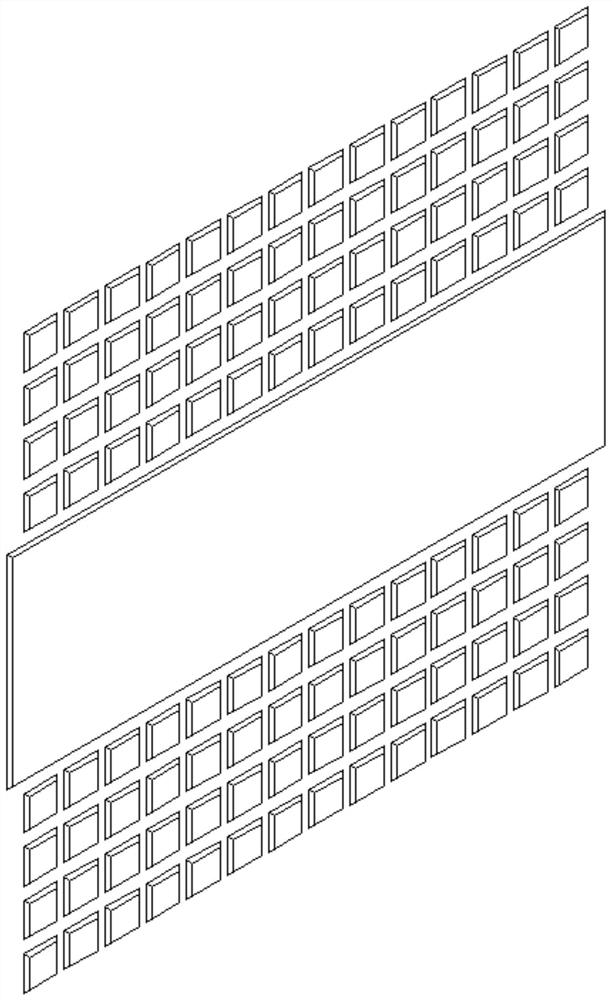

Image

Examples

example 1

[0030] In step S3, the ratio of tin paste is prepared according to the metal content such that the proportion of Tin is set to 90%, the proportion of Silver is set to 1%, the proportion of Cooper is set to 1%, and the proportion of Flux is set to 8%.

example 2

[0032] In step S3, the proportion of solder paste prepared according to the metal content is set as 80% for Tin, 4.5% for Silver, 0.5% for Cooper, and 15% for Flux.

example 3

[0034] In step S3, the proportion of solder paste prepared according to the metal content is set as 85% for Tin, 3.5% for Silver, 0.5% for Cooper, and 11% for Flux.

[0035] In summary, the ratio of solder paste in Example 3 is the best.

[0036] Under the premise of not making changes to the design of PCB and shunt, through the optimization of the proportion of solder paste and the shape of the opening of the stencil, the problem of air bubble rate is effectively improved, and the influence of air bubble rate problem on soldering reliability is solved, and It also solves the influence of changes in the air bubble rate that may be caused by changes in other welding conditions, so that the air bubble rate can be stably controlled within a safe range, which has a greater impact on the welding reliability of the patch shunt and the reliability of the entire vehicle. great promotion.

[0037] It is an essential process to weld the SMD shunt through the reflow furnace. Bubbles are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com