Straight nail bin structure of intracavity cutting anastomat

A straight-type, internal cutting technology, applied in the field of medical devices, can solve the problems of low bearing strength, high replacement costs, and high medical costs, and achieve the effects of convenient and simple disassembly and assembly, light disassembly process, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The present case will be clearly described below with drawings and detailed descriptions. After understanding the embodiments of this case, any person skilled in the art can make changes and modifications by the techniques taught in this case, which does not deviate from the spirit and scope of this case.

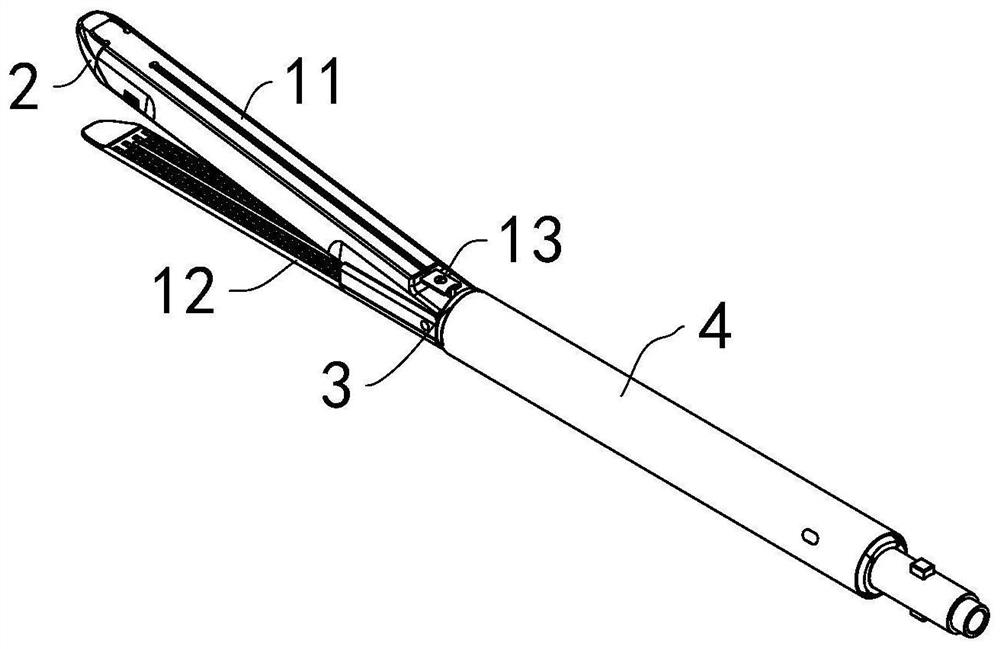

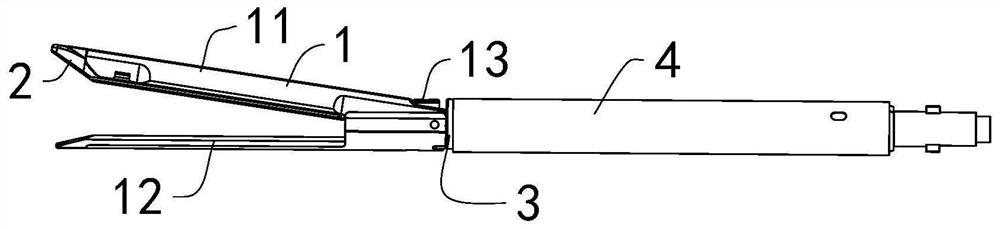

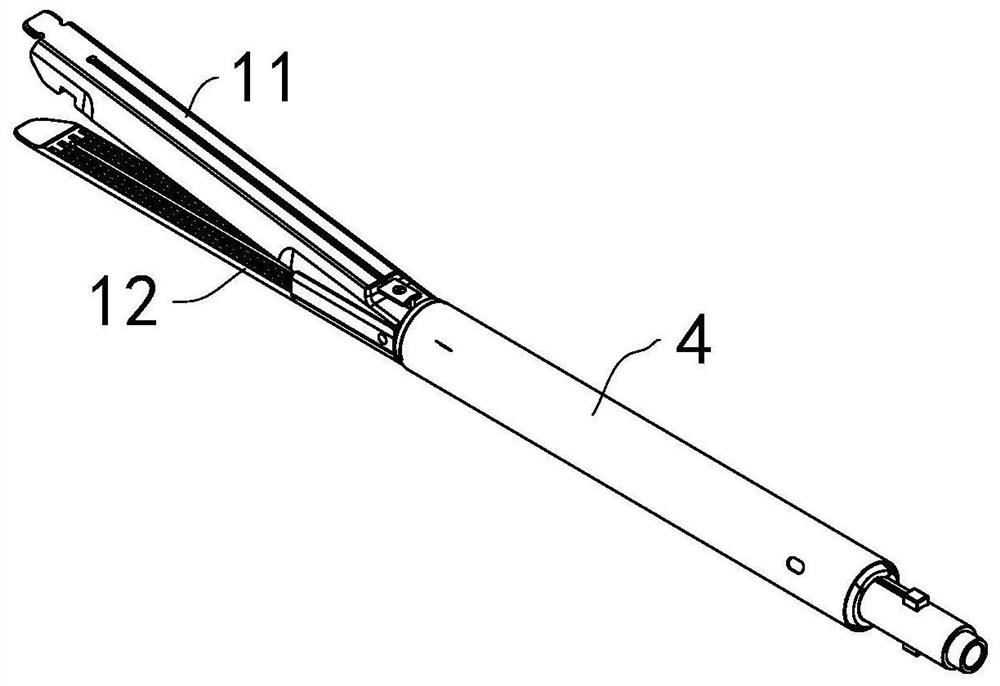

[0088] An embodiment of the present invention discloses a straight staple cartridge structure for an intraluminal cutting stapler, as shown in the attached figure 1 to the attached figure 2 As shown, it includes a staple cartridge holder with a knife, a staple assembly, a connecting assembly, and an outer sleeve, and the end facing the doctor is defined as the rear end, and the end away from the doctor is the front end. In rack assembly 1; of which:

[0089] as attached image 3 to the attached Figure 4 As shown, the bladed staple cartridge holder assembly 1 includes a staple cartridge holder 11 and a staple anvil seat 12. The staple cartridge holder 11 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com