Efficient scalpel sterilization device for neurology department

A sterilizing device and neurology technology, applied in water supply devices, sanitary equipment for toilets, heating, etc., can solve the problems of inconvenient feeding and retrieving materials, long time consumption of high temperature sterilization and ozone sterilization, etc., and achieve shortening The effect of long sterilization time and convenient feeding and retrieving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

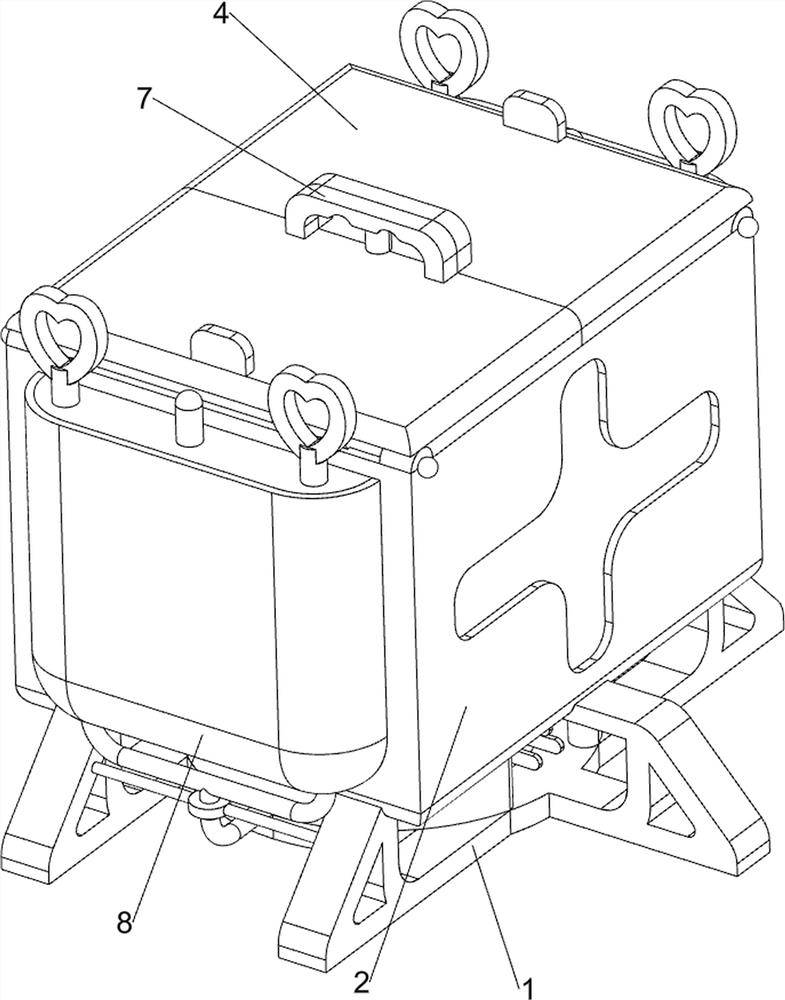

[0030] A high-efficiency sterilization device for scalpels in neurology, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a support frame 1, a placement frame 2, a heating tube 3, a placement mechanism 4 and a sterilization mechanism 5. The top of the support frame 1 is provided with a placement frame 2, and the lower part of the placement frame 2 is provided with a heating tube 3. A placing mechanism 4 is provided, and a sterilizing mechanism 5 is provided on the top of the support frame 1, and the sterilizing mechanism 5 is located at the lower part of the placing frame 2.

[0031] Placement mechanism 4 includes cover plate 41, limit plate 42, pull ring 43, block 44 and first spring 45, and placement frame 2 top left and right symmetrical rotations are provided with cover plate 41, placement frame 2 insides are provided with up and down symmetrical sliding type. Limit plate 42, limit plate 42 tops are all symmetrically provided with...

Embodiment 2

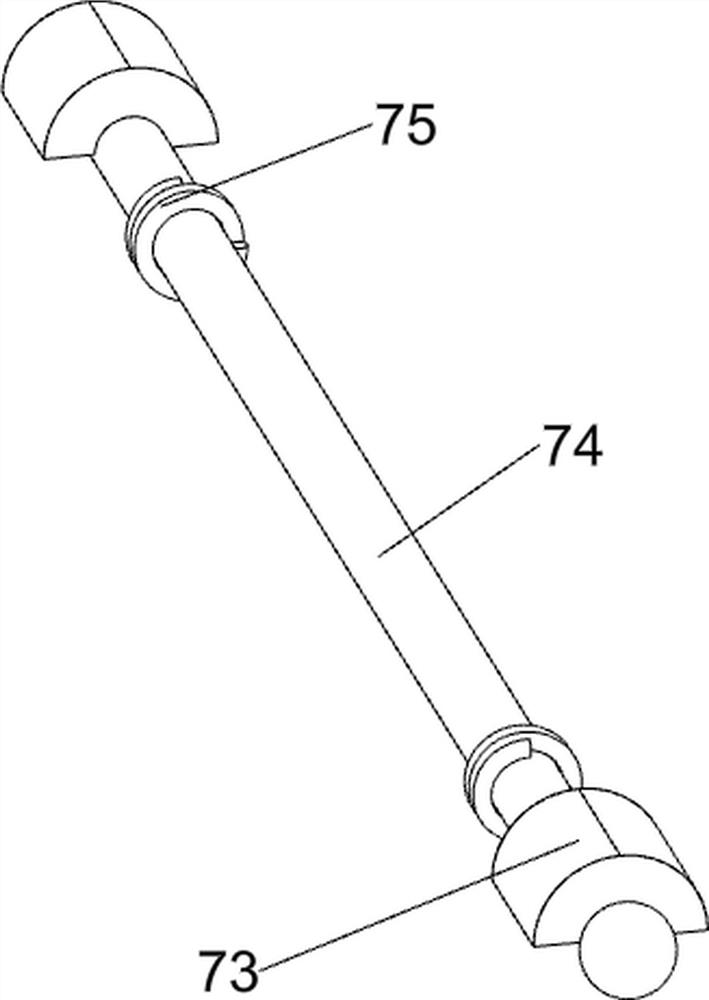

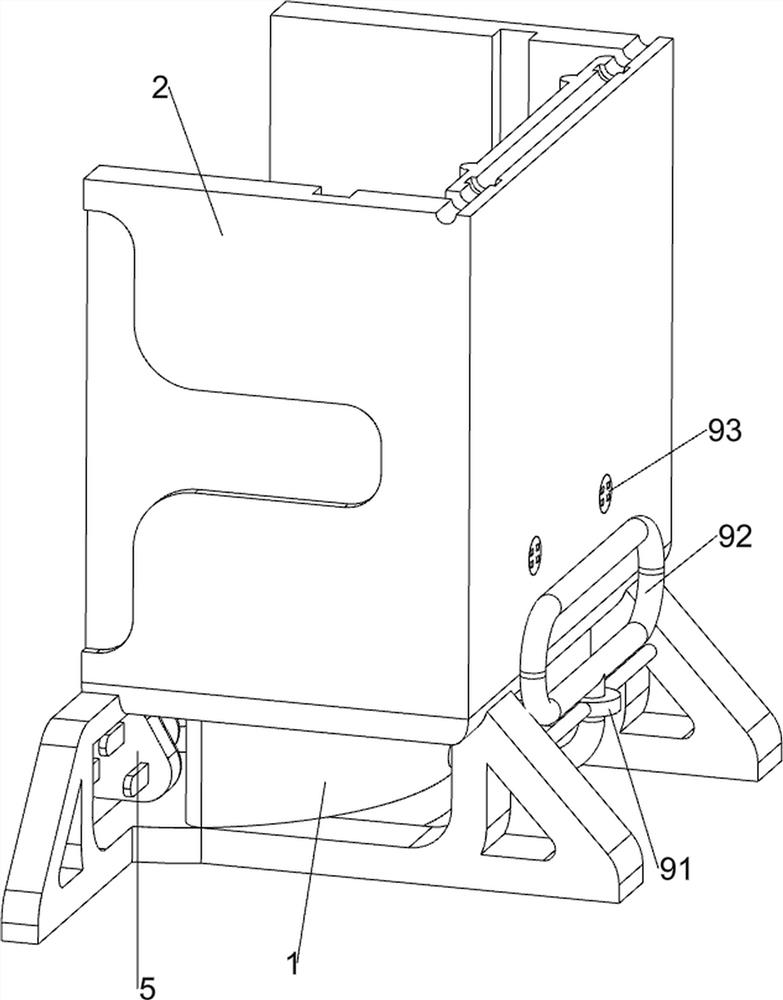

[0035] On the basis of Example 1, such as Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a lifting assembly 6 is also included. The lifting assembly 6 includes a baffle plate 61, a first guide rod 62, a second spring 63, a pull rod 64, a limit block 65 and a connecting rod 66, and the lower side of the placement frame 2 is left and right symmetrical. A first guide rod 62 is provided, and a baffle plate 61 is slidably arranged between the first guide rods 62. The baffle plate 61 cooperates with the limit plate 42, and a second spring 63 is arranged between the baffle plate 61 and the first guide rod 62. , the second springs 63 are all set on the first guide rod 62, and the front and rear sides of the baffle plate 61 are symmetrically provided with pull rods 64, and the pull rods 64 are all slidably connected with the inner wall of the placement frame 2, and the middle part of the inner wall of the placement frame 2 is symmetrically provided with two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com