A multi-stage cold extrusion strengthening device and its application method

A strengthening device and cold extrusion technology, applied in the direction of the metal extrusion mandrel, etc., can solve the problems of large single extrusion volume, damage of elastic-plastic deformation zone, and long time consumption, etc., and achieve small single extrusion volume , reduce processing damage, improve the effect of strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

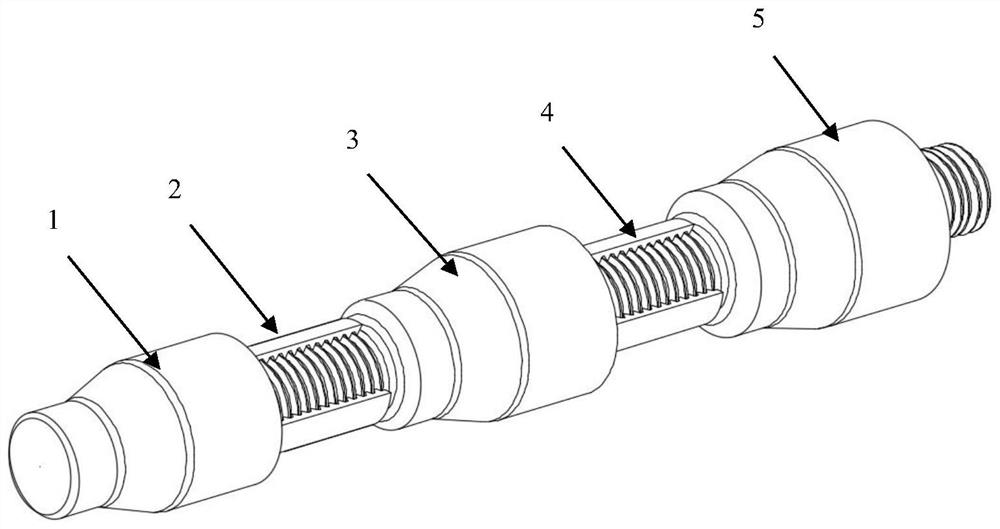

[0038] Such as figure 1 and figure 2 As shown, the present invention provides a multi-stage cold extrusion strengthening device, such as figure 1 As shown, taking the three-section extruded mandrel as an example, it includes the first extruded mandrel 1, the second extruded mandrel 3 and the third extruded mandrel 5, and also includes the second sleeve 2 and the second extruded mandrel for connection. a sleeve4.

[0039] Wherein, between the first extruding mandrel 1 and the second extruding mandrel 3, through the second sleeve 2 coaxial detachable connection, between the third extruding mandrel 5 and the second extruding mandrel 3 The first sleeve 4 is coaxially and detachably connected, and the maximum diameters of the first extruding mandrel 1 , the second extruding mandrel 3 and the third extruding mandrel 5 gradually increase.

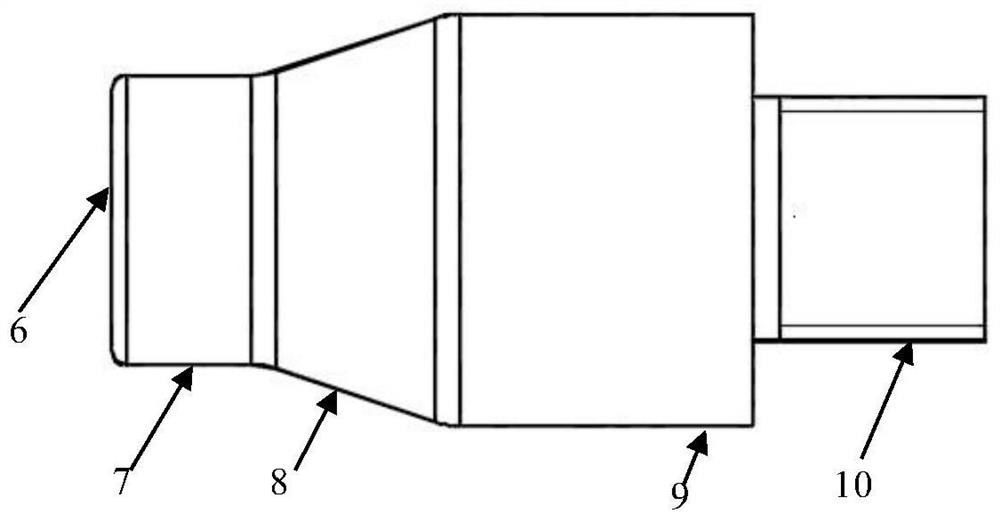

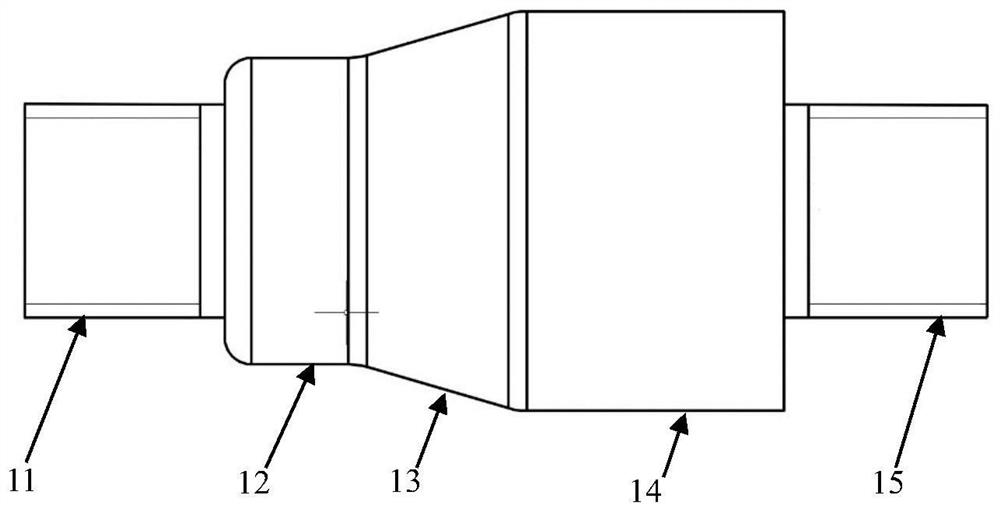

[0040] The first extruded mandrel 1 is composed of four parts along the axis: a guide section, an extrusion section, an extrusion section, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com