Rotary cutting tool for wire cutting of part

A rotary cutting and wire cutting technology, which is applied in the field of parts cutting, can solve the problems such as the peripheral processing of circular shaft-shaped parts, and achieve the effects of improving efficiency, expanding the processing range, and simplifying manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

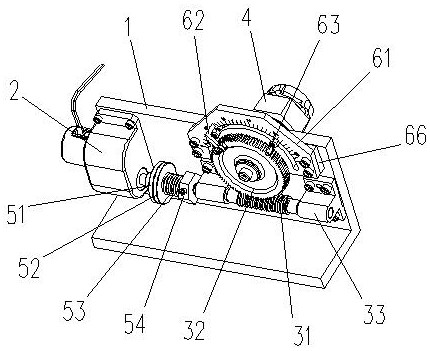

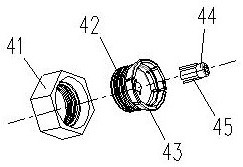

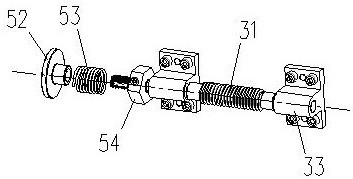

[0026] Example: see Figure 1-Figure 4 , a rotary cutting tool for wire cutting parts, including a fixed support 1, a driving motor 2, a transmission mechanism and a workpiece gripper 4. The fixed support 1 has a bearing plate. In practice, the fixed support 1 also includes a base plate, on which there are installation holes for connecting with the machine tool of the cutting machine. The bearing plate is installed on the bottom plate, and the entire fixed support 1 is L-shaped or T-shaped. The driving motor 2 is fixedly installed on one side of the bearing plate, and the transmission mechanism and the driving motor 2 are located on the same side of the bearing plate, and are connected with the driving motor 2 through a clutch mechanism, which includes a worm 31, a worm gear 32 and a worm gear 32 shaft; The two ends of the worm 31 are respectively connected to the bearing plate through a worm seat 33, and can freely rotate around its axis; the worm wheel 32 is fixedly connect...

Embodiment approach

[0027]During specific implementation, the clutch mechanism includes an active friction disc 51 and a driven friction disc 52, the active friction disc 51 is connected with the output shaft of the drive motor 2, the driven friction disc 52 is connected with the end of the worm 31 close to the drive motor 2, and the active friction disc The disk 51 and the driven friction disk 52 are in close contact with each other, and the driven friction disk 51 can drive the driven friction disk 52 to rotate and drive the worm 31 to rotate. With this solution, the driving motor 2 drives the active friction disc 51 to rotate, and the active friction disc 51 and the driven friction disc 52 rub against each other to transmit torque, so that the driven friction disc 52 rotates, and then drives the worm 31 to rotate; the structure is simple and easy to assemble and adjust. As an embodiment, the clutch mechanism also includes a compression spring 53 and an adjustment nut 54, the adjustment nut 54 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap