Intelligent manufacturing grinding machine for new energy automobile parts

A new energy vehicle and intelligent manufacturing technology, applied in manufacturing tools, machine tools designed for grinding the rotating surface of workpieces, grinders, etc., can solve problems such as safety hazards caused by sparks splashing, powder pollution of the working environment, and impact on the health of workers. , to achieve the effect of reducing pollution and solving potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

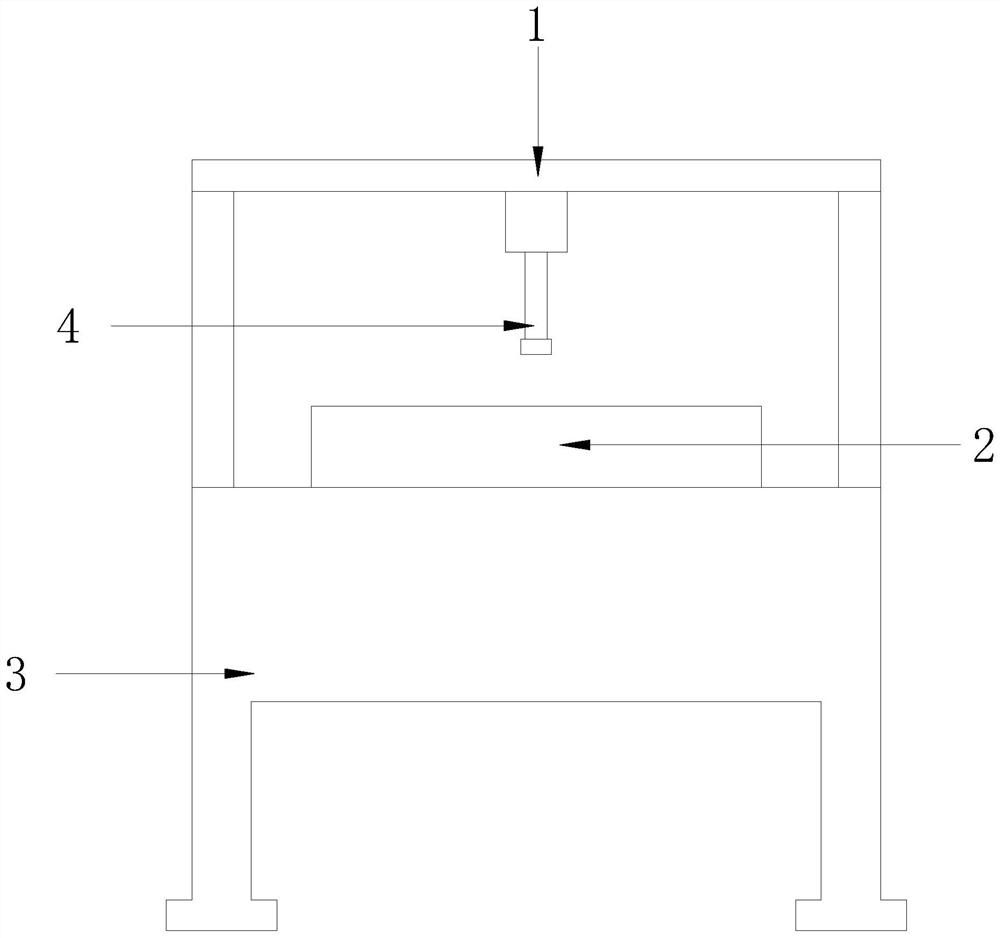

[0027] see Figure 1-4 , the present invention provides a new energy auto parts intelligent manufacturing grinding machine, a new energy auto parts intelligent manufacturing grinding machine, its structure includes a frame 1, a processing seat 2, a base 3, a grinding mechanism 4, the base 3 is installed with A processing seat 2, a frame 1 is fixed on the surface of the base 3, and the frame 1 is connected with the grinding mechanism 4;

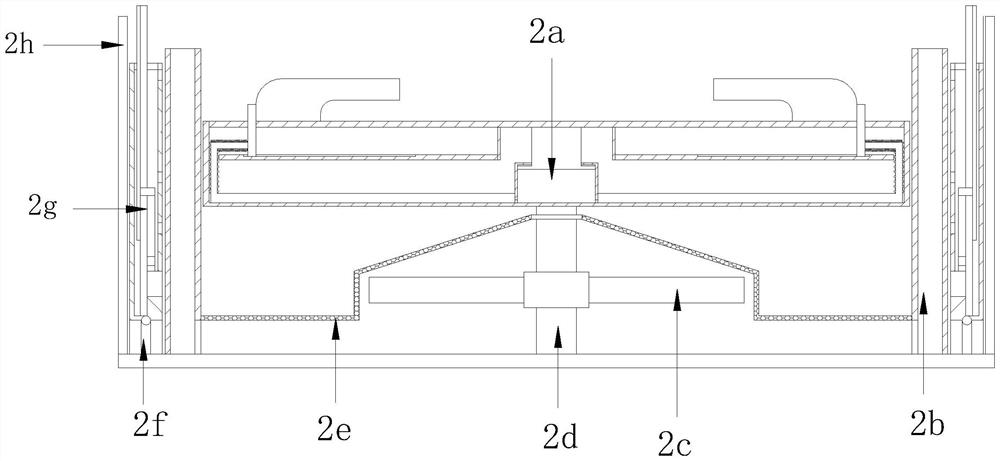

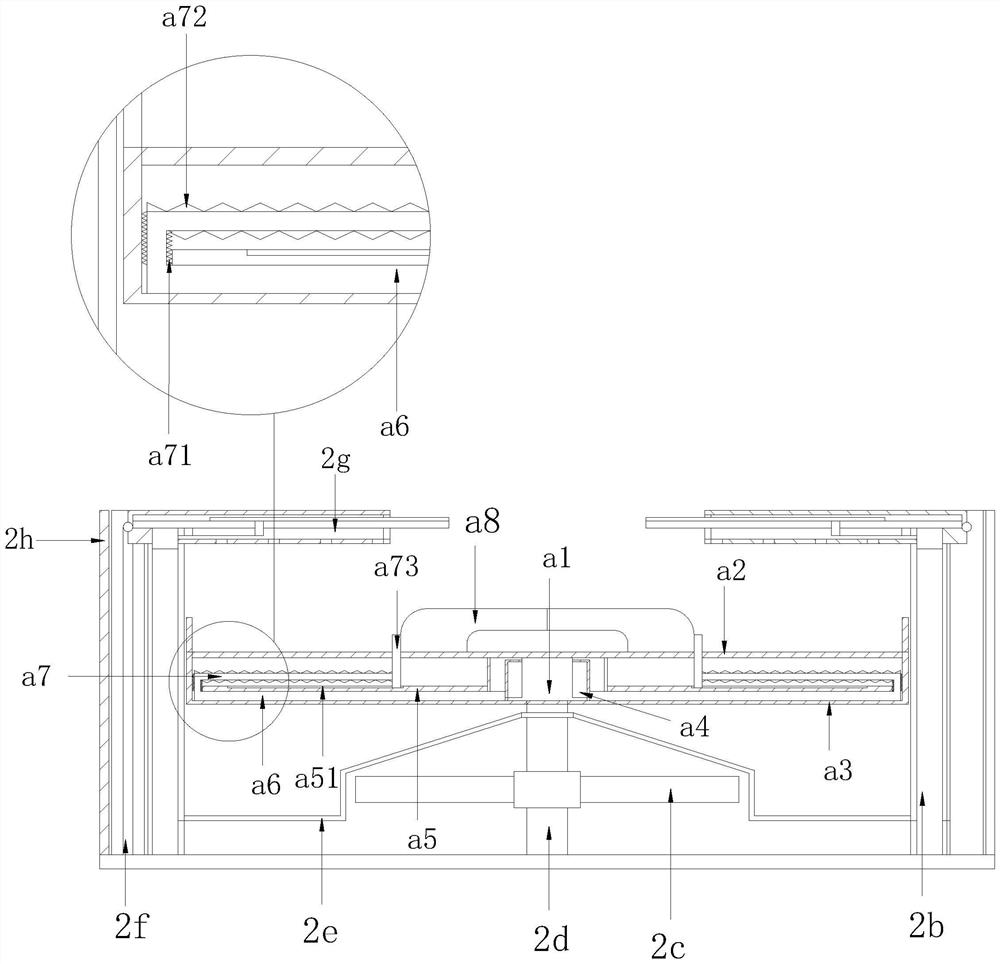

[0028] The processing seat 2 includes a fixing device 2a, an air duct 2b, an exhaust fan 2c, a rotating shaft 2d, a filter box 2e, a slideway 2f, a blocking mechanism 2g, and a seat body 2h, and the bottom of the fixing device 2a is connected to the rotating shaft 2d , the rotating shaft 2d is provided with an exhaust fan 2c and is transitionally matched with it, the rotating shaft 2d runs through the filter box 2e and the two do not interfere with each other, and the filter box 2e is located between the fixing device 2a and the exhaust fan 2c...

Embodiment 2

[0035] see Figure 1-3, the present invention provides a grinding machine for intelligent manufacturing of new energy auto parts, its structure includes a frame 1, a processing seat 2, a base 3, and a grinding mechanism 4, the processing base 2 is installed on the base 3, and the surface of the base 3 is fixed with Frame 1, the frame 1 is connected with the grinding mechanism 4, the processing seat 2 includes a fixing device 2a, an air channel 2b, an air exhaust fan 2c, a rotating shaft 2d, a filter box 2e, a slideway 2f, a blocking mechanism 2g, a seat body 2h, the bottom of the fixing device 2a is connected with the rotating shaft 2d, the rotating shaft 2d is provided with an exhaust fan 2c and is transitionally matched with it, the rotating shaft 2d runs through the filter box 2e and the two do not interfere with each other, the filter The net box 2e is located between the fixing device 2a and the exhaust fan 2c, and the inner wall of the seat body 2h is provided with a sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com