Tooth opening type connecting structure of zigzag-form steel web and concrete slab

A technology of concrete slabs and connecting structures, which is applied in bridge materials, bridges, buildings, etc., can solve the problems of difficult penetration of steel bars, etc., to increase the tensile bearing capacity and stiffness, improve convenience, and improve shear bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

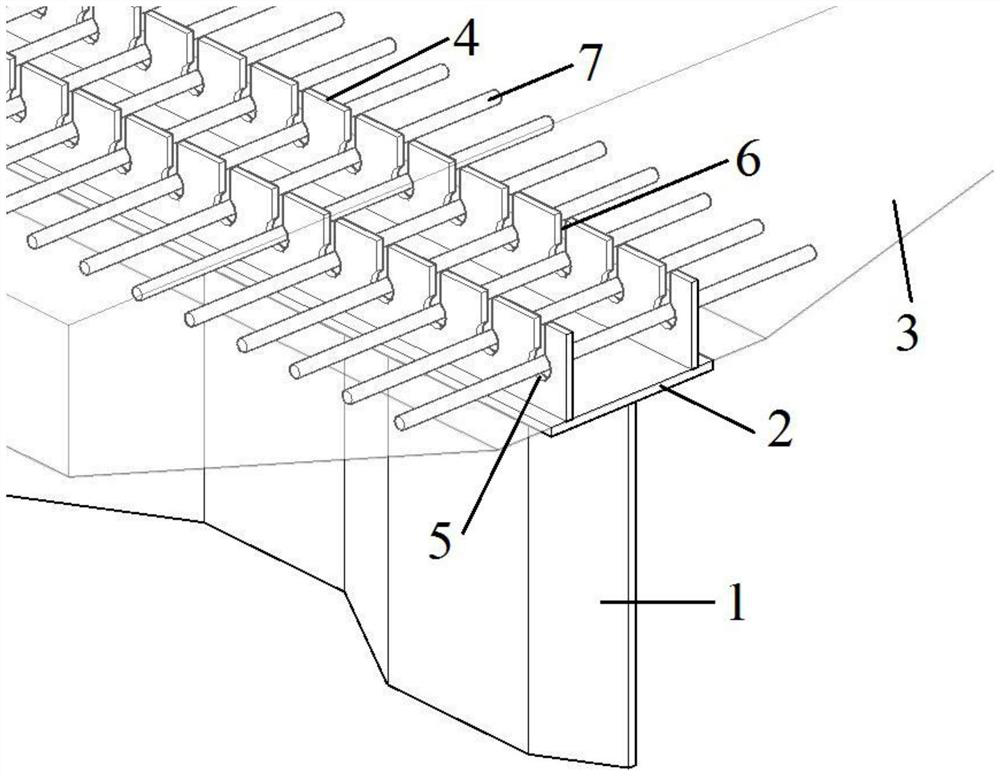

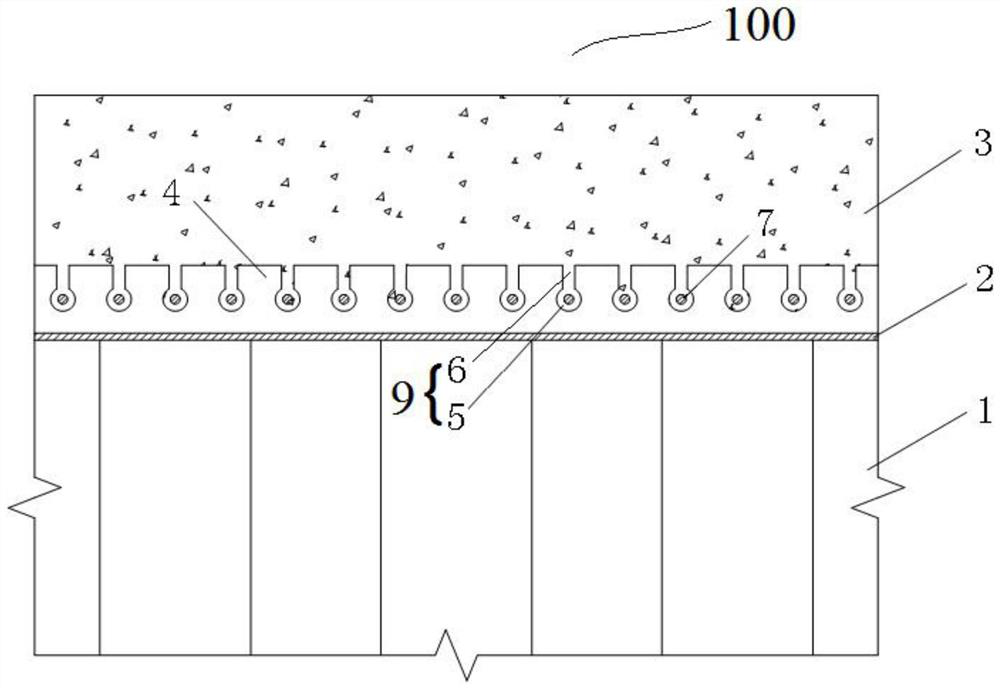

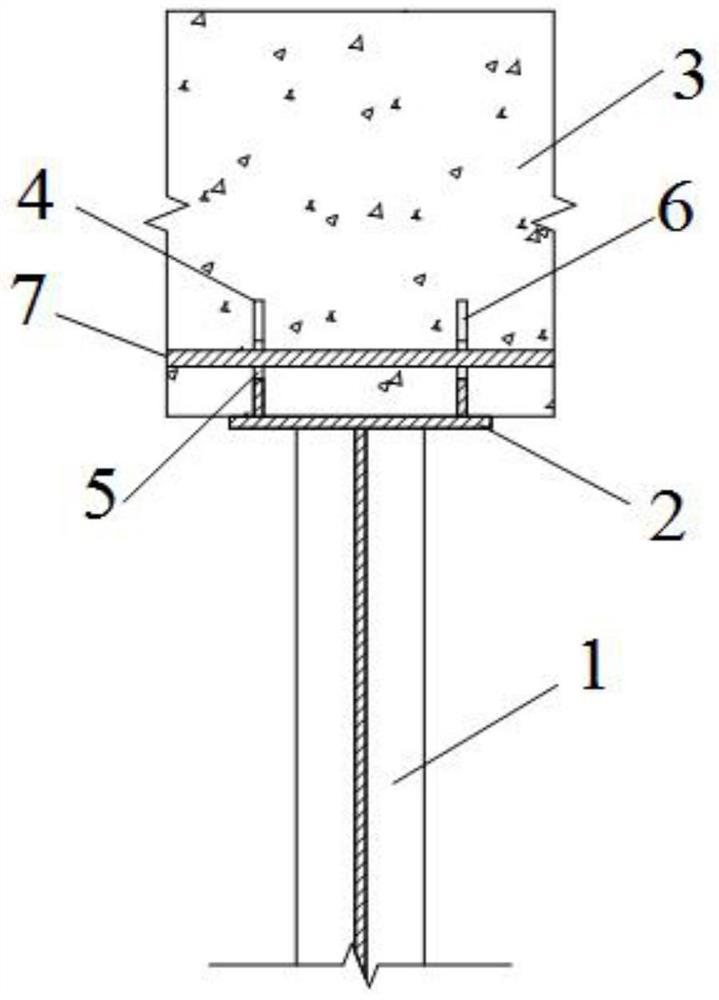

[0030] Such as Figure 1 to Figure 3 As shown: this embodiment provides a tooth mouth connection structure 100 between a folded steel web and a concrete slab 3, including a folded steel web 1, a flange steel plate 2, a concrete slab 3, a plurality of perforated steel bars 7 and Two perforated steel plates4.

[0031] Among them, the bottom surface of the flange steel plate 2 is welded to the top of the folded steel web 1, and the folded steel web 1 is perpendicular to the bottom surface of the flange steel plate 2; the bottom of the perforated steel plate 4 is welded to the top surface of the flange steel plate 2 , the perforated steel plate 4 is perpendicular to the top surface of the flange steel plate 2, the folded steel web 1 and the perforated steel plate 4 are arranged longitudinally; gaps 9 distributed at intervals, and the opening of the gap 9 is located at the top edge of the perforated steel plate 4, the perforated steel bar 7 is inserted in the notch 9, and the mini...

Embodiment 2

[0035] Such as Figure 4 to Figure 7 As shown: this embodiment provides a spline connection structure 100 between a folded steel web and a concrete slab 3, and the spline connection structure 100 between a folded steel web and a concrete slab 3 in this embodiment is the same as that in Embodiment 1 The provided folded steel web and the tooth mouth connection structure 100 of the concrete slab 3 are basically the same in structure, the difference is that in the tooth mouth connection structure 100 of the folded steel web and the concrete slab 3 in this embodiment The gap 9 on the perforated steel plate 4 is in the shape of an inverted "Ω". The advantage of this arrangement is that when the perforated steel plate 4 is cut and made, it can be cut along the steel plate cutting line 8 on a whole steel plate. Two perforated steel plates 4 can be obtained, which improves the manufacturing efficiency and steel plate utilization rate. In the same way, the shape of the gap 9 on the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com