Three-dimensional vibration hydraulic oscillator and machining method

A hydraulic oscillator and three-dimensional vibration technology, which is applied in the direction of drilling with vibration, can solve the problems of uncontrollable frequency, difficult to control, and many rotating parts, and achieves the effect of solving manufacturing problems, facilitating transmission and simplifying the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

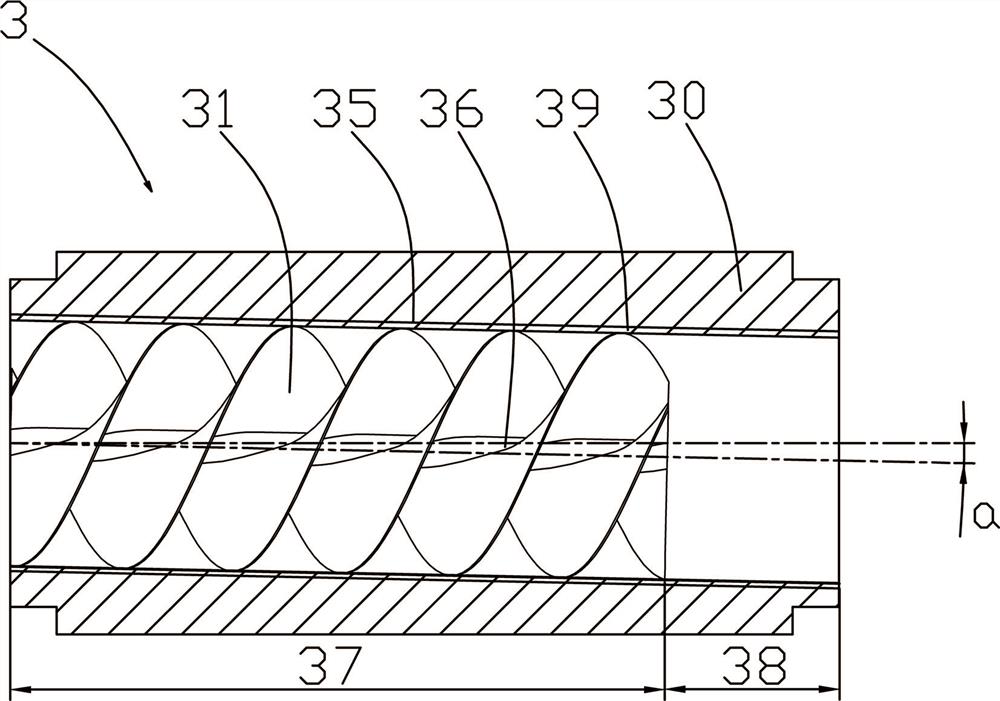

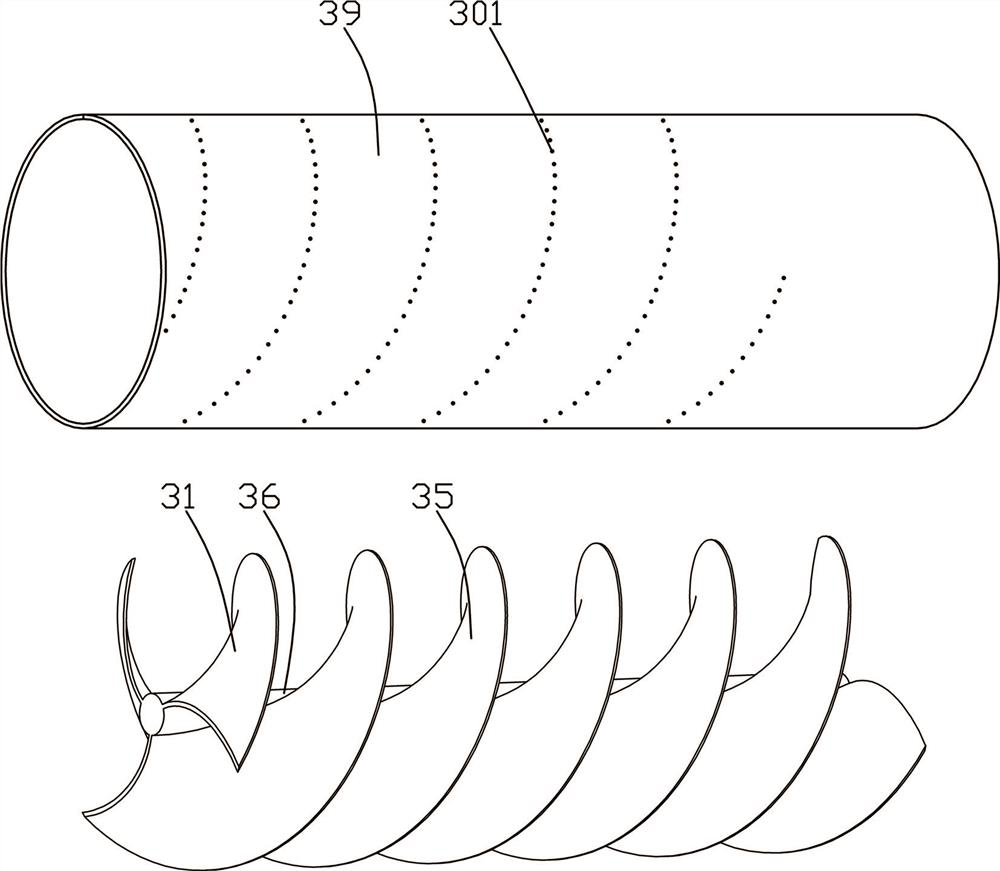

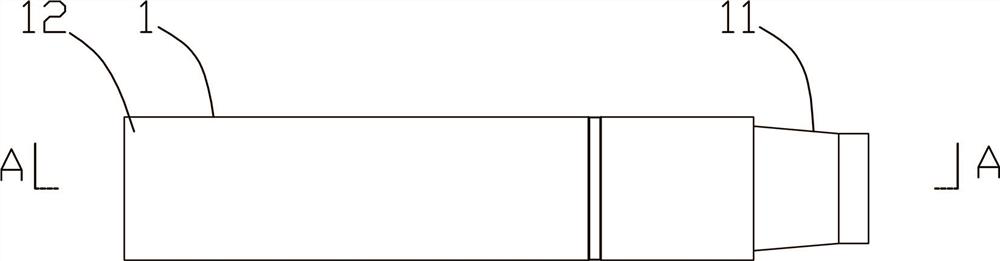

[0042] A three-dimensional vibrating hydraulic oscillator, which includes a pipe body 1. An eccentric turbine 3 is arranged inside the pipe body 3. A relatively rotatable sliding socket structure is formed between the outer wall of the eccentric turbine 3 and the inner wall of the pipe body 1. The eccentric turbine 3 The turbine body 30 is provided with an inclined hole 35 penetrating in the axial direction. There is an angle a between the inclined hole 35 and the axis of the pipe body 1. The inner wall of the inclined hole 35 is provided with an inner sleeve 39, and the inner sleeve 39 is fixed. There are turbine blades 31;

[0043] A fixed valve plate 4 is also provided in the pipe body 1, and the fixed valve plate 4 is located at the downstream of the eccentric turbine 3. The eccentric turbine 3 is in contact with the fixed valve plate 4. The flow hole 41 and the flow hole 41 are eccentric holes. The size of the flow section between the inclined hole 35 and the flow hole 4...

Embodiment 2

[0055] The solution in Example 1 can realize the radial and axial composite vibration of the drilling tool with a simplified structure, and the realization cost is relatively low, so it has broad application prospects, but the eccentric turbine 3 is relatively difficult to process. In order to solve this technical problem. On the basis of Embodiment 1, a method for processing the above-mentioned three-dimensional vibration hydraulic oscillator comprises the following steps:

[0056] S1. Machining and forming the turbine blade 31; the turbine blade 31 is usually rolled and formed on special rolling roller equipment.

[0057] S2. Weld the turbine blades 31 together through the connecting columns 36 to form a turbine blade assembly; during the welding process, a tool for fixing the turbine blades 31 is required to ensure the connection accuracy between the turbine blades 31 and the connecting columns 36 .

[0058] S3. Finishing the outer contour shape of the turbine blade assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com