Mounting method of process reciprocating compressor

An installation method and reciprocating technology, which is applied in the direction of liquid variable-capacity machinery, mechanical equipment, variable-capacity pump components, etc., can solve the problems that the centrifuge cannot reach the height, the compressor cannot be cleaned, and the stable installation can reduce pollution. , the effect of preventing damage to equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

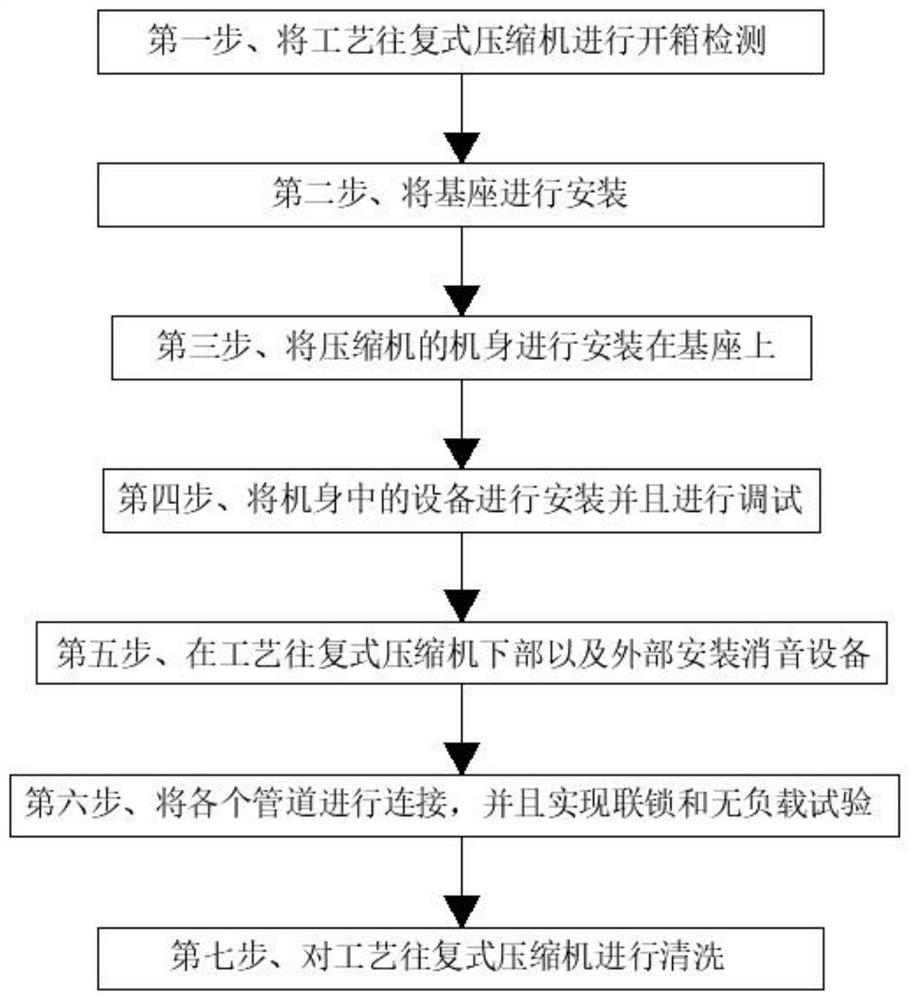

[0029] A method for installing a process reciprocating compressor includes the following method steps:

[0030] S1. Unpack the process reciprocating compressor for inspection: unpack the process reciprocating compressor, and inspect and process the equipment structure of the process reciprocating compressor, and the inspection requirements include determining the components of the process reciprocating compressor Completeness of parts and performance of parts;

[0031] S2. Install the base: compact the ground, pour the base through concrete, and grout the fuselage anchor bolts at the same time;

[0032] S3. Install the body of the compressor on the base: first align and level the equipment of the process reciprocating compressor, and determine the vertical deviation of the main shaft and the slideway, then revise it, and then install the process reciprocating compressor Fixed installation by bolts;

[0033] S4. Install and debug the equipment in the fuselage: install the con...

Embodiment 2

[0046] Embodiment 2: The difference from Embodiment 1 is that the equipment is fixedly installed on the rack;

[0047] S1. Unpack the process reciprocating compressor for inspection: unpack the process reciprocating compressor, and inspect and process the equipment structure of the process reciprocating compressor, and the inspection requirements include determining the components of the process reciprocating compressor Completeness of parts and performance of parts;

[0048] S2. Weld the frame and fix the base: use steel channel to weld the frame, then fix the base to the frame by welding or through bolts, and install the sound-absorbing protective shell on the frame;

[0049] S3. Install the body of the compressor on the base: first align and level the equipment of the process reciprocating compressor, and determine the vertical deviation of the main shaft and the slideway, then revise it, and then install the process reciprocating compressor Fixed installation by bolts;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com