Novel cold forging type radiator for LED car lamp

A kind of LED car lamp, cold forging technology, applied in the cooling/heating device of lighting device, semiconductor device of light-emitting element, vehicle parts, etc., can solve the problem of poor heat dissipation effect, inconvenient radiator disassembly, inconvenient wire protection function and other issues to achieve the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

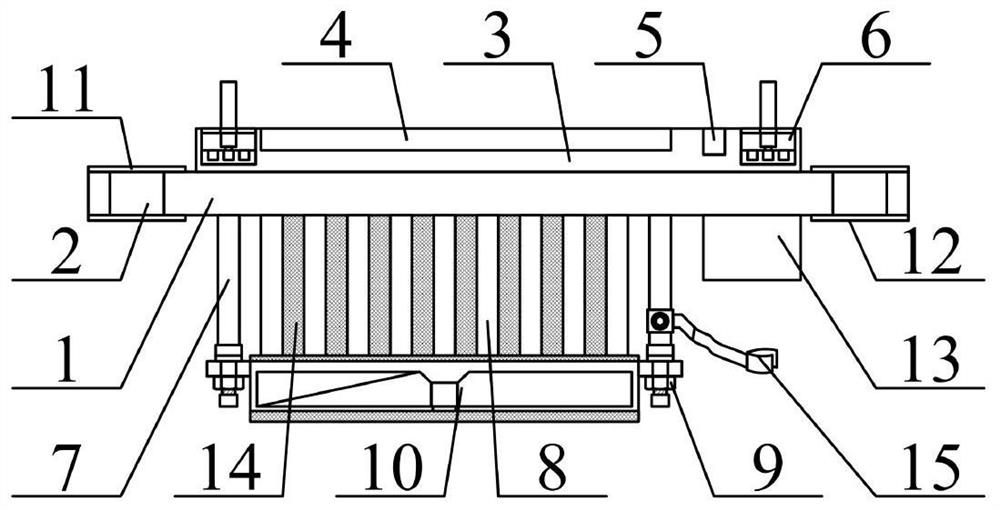

[0037] as attached figure 1 And attached Figure 4 shown

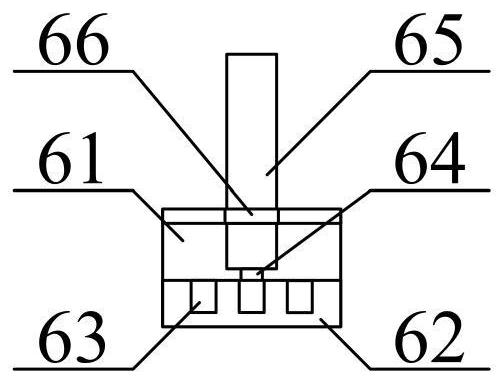

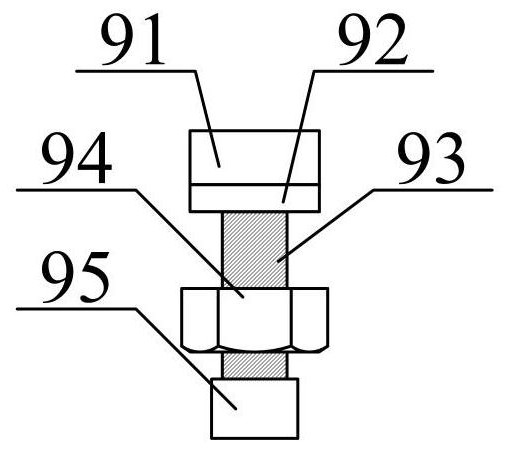

[0038]The present invention provides a new type of cold-forged heat sink for LED lights, which includes a cooling plate 1, a mounting hole 2, an interface material plate 3, a car light circuit board 4, a wiring hole 5, an adjustable positioning frame structure 6, and a side Cooling rod 7, central cooling rod 8, easy to disassemble the mounting frame structure 9, auxiliary cooling frame structure 10, upper side protection pad 11, lower side protection pad 12, junction box 13, side protection net 14 and adjustable protection frame structure 15 , the mounting holes 2 are opened on the left and right sides of the heat dissipation plate 1; the interface material plate 3 is welded on the upper part of the heat dissipation plate 1; the lamp circuit board 4 is embedded in the upper part of the interface material plate 3; The wiring hole 5 described above is opened on the upper right side of the interface material plate 3; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com