Self-cleaning sterilization control method and device for air conditioner, air conditioner and storage medium

A control method and technology for air conditioners, which are applied in space heating and ventilation, heating and ventilation control systems, heating methods, etc., can solve problems such as drive out-of-step failure shutdown, refrigeration system pressure exceeding the standard, and reducing compressor reliability, etc. To achieve the effect of reducing the total time, avoiding excessive temperature, and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

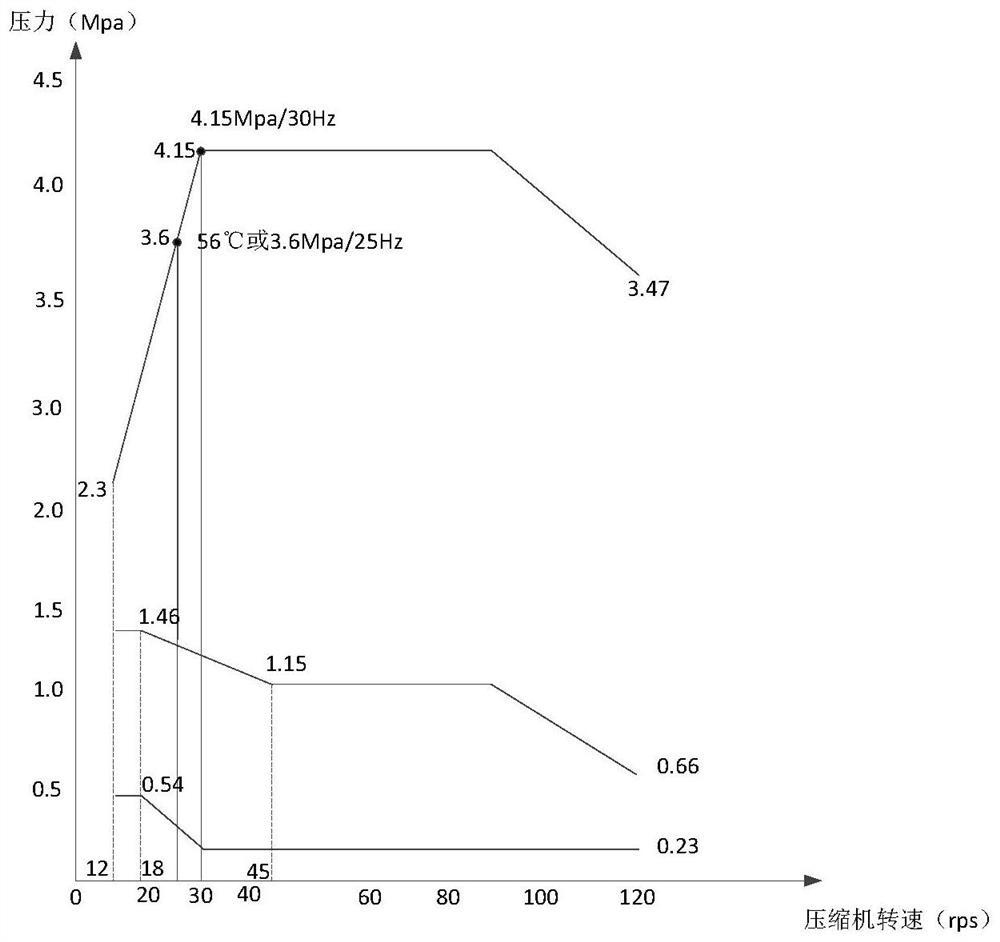

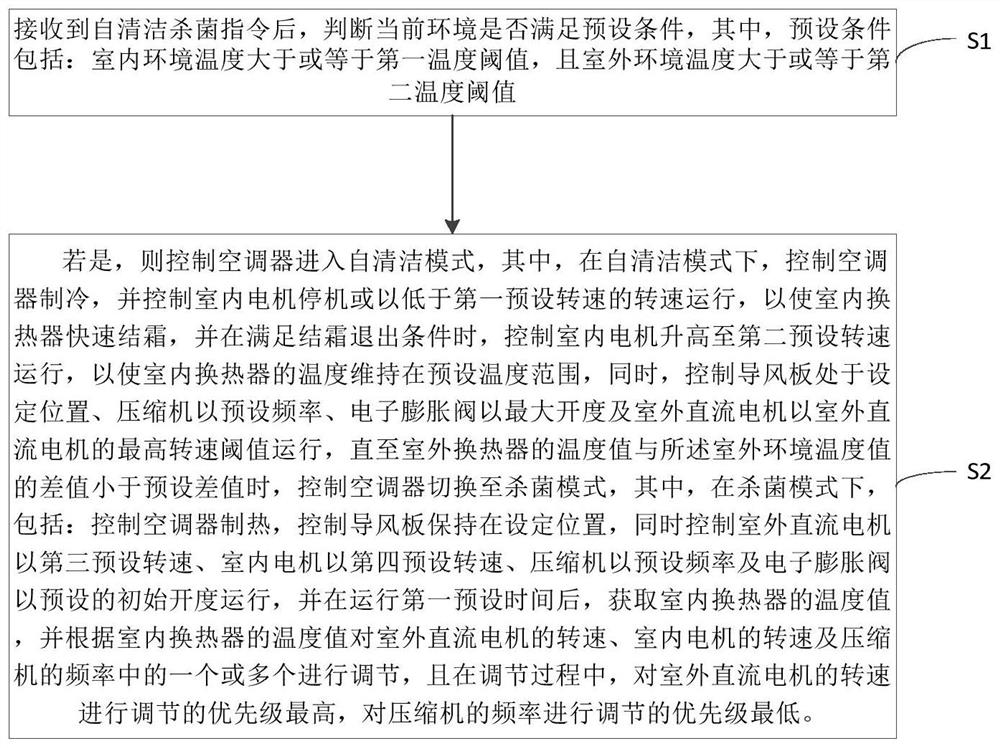

[0072] Embodiment 1, the air conditioner receives a self-cleaning and sterilization command, and detects that the indoor ambient temperature Tin=27°C and the outdoor ambient temperature Tout=33°C. At this time, it is considered that the indoor ambient temperature Tin is greater than the first temperature threshold T1, and the outdoor ambient temperature Tout is greater than The second temperature threshold T2 determines that the current environment meets the preset conditions, controls the air conditioner to enter the self-cleaning mode, and proceeds to the first stage, that is, the frosting stage, controls the air conditioner to cool, the indoor motor stops, and the indoor heat exchanger is in the frosting stage , when the frosting exit condition is met, enter the second stage, that is, the frosting water stage, and perform the following actions at the same time: a. The speed of the indoor motor is switched from the current speed or stop state to the low wind gear r_L=800rpm, a...

Embodiment 2

[0073] Embodiment 2, the air conditioner receives the self-cleaning and sterilization instruction, detects that the indoor ambient temperature Tin=27°C, and the outdoor ambient temperature Tout=42°C, at this time, it is considered that the indoor ambient temperature Tin is greater than the first temperature threshold T1, and the outdoor ambient temperature Tout is greater than The second temperature threshold T2 determines that the current environment meets the preset conditions, controls the air conditioner to enter the self-cleaning mode, and proceeds to the first stage, that is, the frosting stage, controls the air conditioner to cool, the indoor motor stops, and the indoor heat exchanger is in the frosting stage , when the frosting exit condition is met, enter the second stage, that is, the frosting water stage, and perform the following actions at the same time: a. The speed of the indoor motor is switched from the current speed or stop state to the low wind gear r_L=800rpm...

Embodiment 3

[0074] Embodiment 3, the air conditioner receives the self-cleaning and sterilization instruction, and detects that the indoor ambient temperature Tin=26°C and the outdoor ambient temperature Tout=30°C. At this time, it is considered that the indoor ambient temperature Tin is greater than the first temperature threshold T1, and the outdoor ambient temperature Tout is greater than The second temperature threshold T2 determines that the current environment meets the preset conditions, controls the air conditioner to enter the self-cleaning mode, and proceeds to the first stage, that is, the frosting stage, controls the air conditioner to cool, the indoor motor stops, and the indoor heat exchanger is in the frosting stage , when the frosting exit condition is met, enter the second stage, that is, the frosting water stage, and perform the following actions at the same time: a. The speed of the indoor motor is switched from the current speed or stop state to the low wind gear r_L=800...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com