Obstacle detection method for overhead transmission line inspection robot

A technology for overhead transmission lines and inspection robots, applied in the field of machine vision, can solve the problems of complex network model computing system, inability to recognize abnormal obstacles, and single type of obstacle recognition, avoiding long-term running reasoning, good robustness The effect of ensuring the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

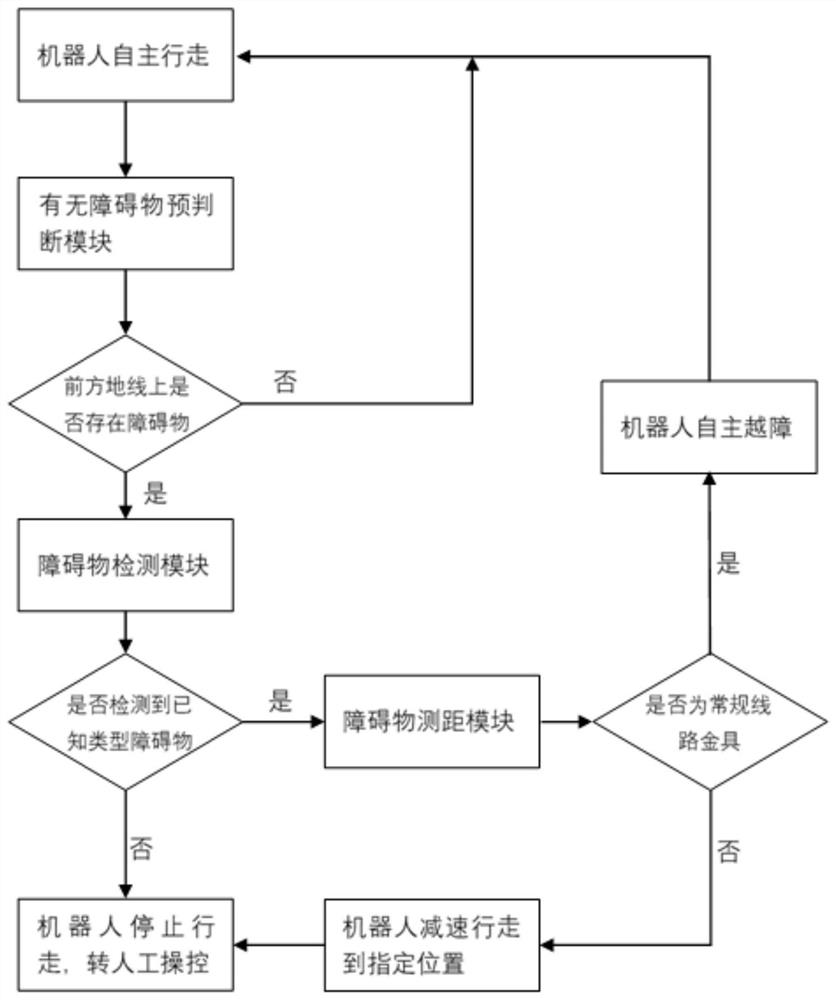

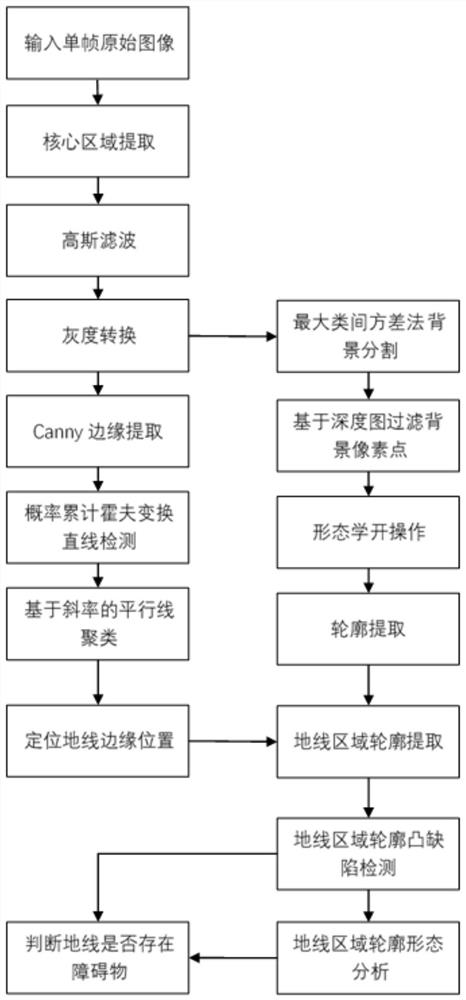

[0043] In order to realize continuous autonomous inspection, the robot needs to identify obstacles on the walking route in advance, and perform corresponding obstacle-crossing actions according to the obstacle type and position information. Conventional obstacles on the ground include line fittings such as anti-vibration hammers and wire clips. The reliability of obstacle detection is crucial to the safe operation of the robot. Wrong judgments will cause huge safety hazards. The applicant found that the existing visual The inspection robot based on the identifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com