Rotating electric machine unit

A technology of rotating motors and rotating speeds, applied in the direction of motors, electrical components, electromechanical devices, etc., can solve the problems of output performance reduction and achieve the effect of suppressing the reduction of output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

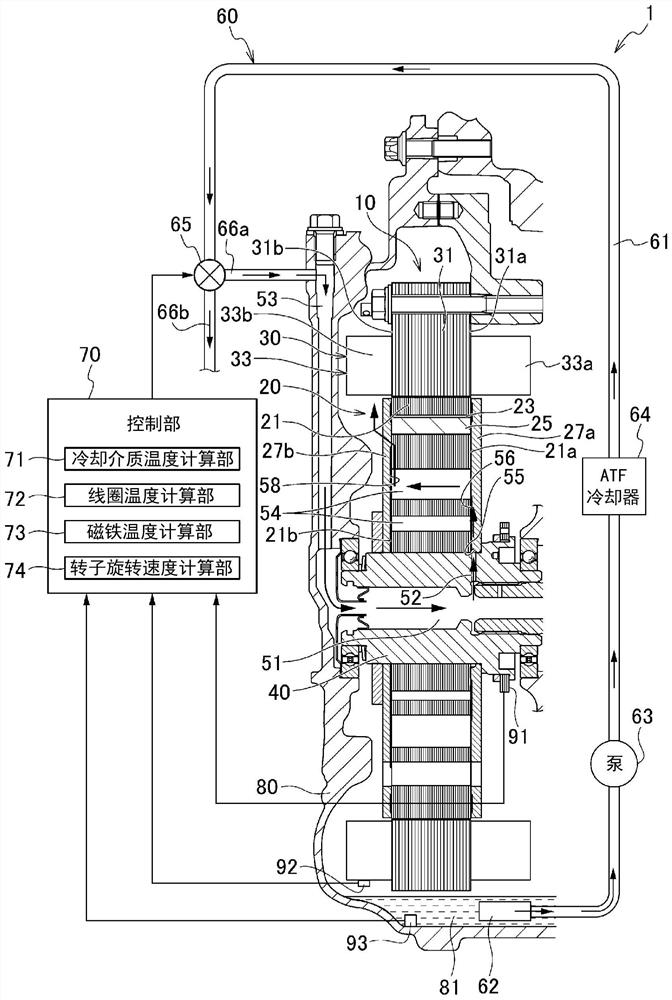

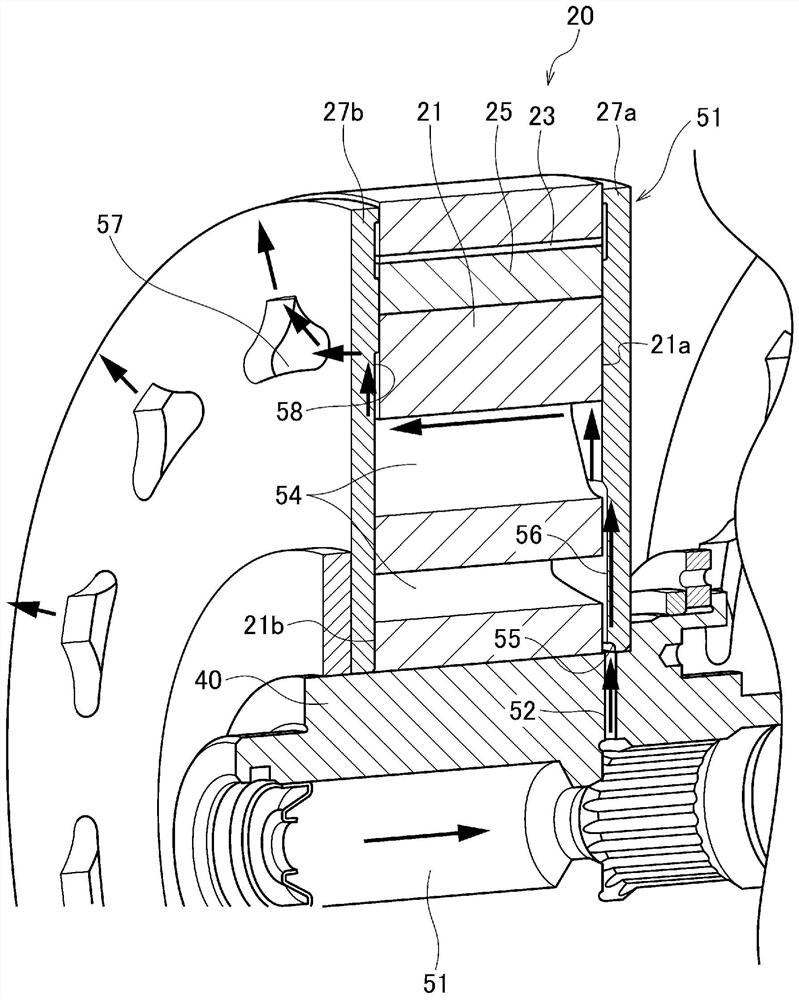

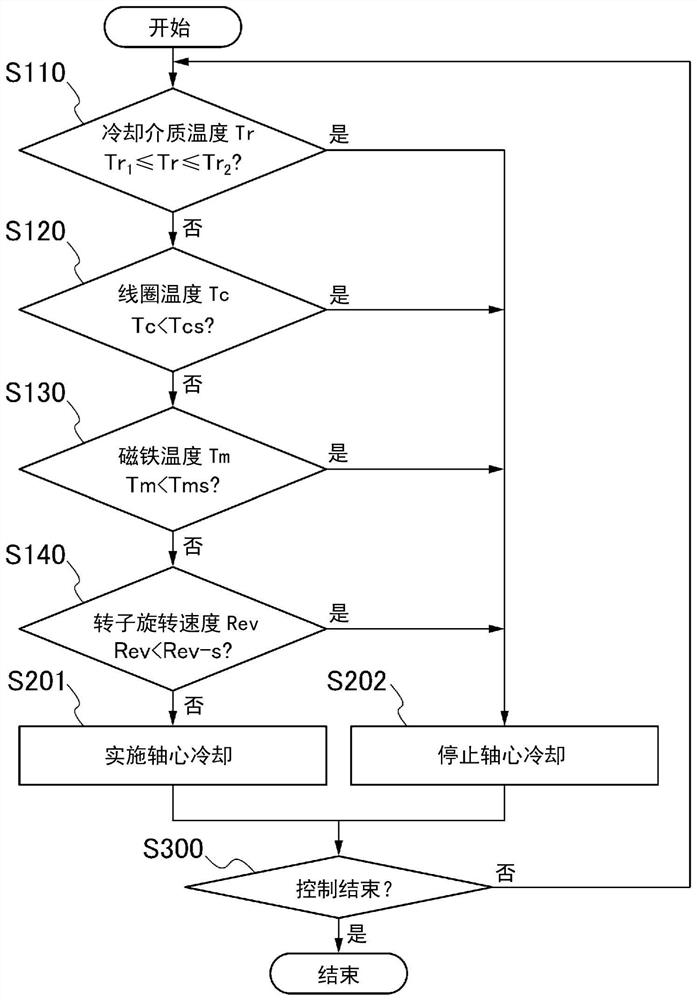

[0051] Hereinafter, an embodiment of the rotating electric machine unit 1 of the present invention will be described based on the drawings.

[0052]

[0053] Such as figure 1 and figure 2 As shown, the rotary electric machine unit 1 of this embodiment includes: a rotary electric machine 10 having a rotor 20 and a stator 30 ; a rotor shaft 40 ; and a cooling medium supply device 60 . The rotating electrical machine 10 and the rotor shaft 40 are accommodated in a housing 80 .

[0054] In addition, in this specification etc., when referring to an axial direction, a radial direction, and a circumferential direction, it means the direction based on the rotation axis of the rotary electric machine 10. In addition, the axially inner side refers to the central side of the rotating electric machine 10 in the axial direction, and the axially outer side refers to a side away from the center of the rotating electric machine 10 in the axial direction.

[0055] The rotor shaft 40 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com