Adjustable printing aluminum plate automatic ink removal gluing machine

An adjustable and automatic technology, applied in the field of gluing machines, can solve the problems of lack of availability, inconvenient scraping of slag, inconvenient collection of slag, etc., to achieve the effect of uniform glue, convenient disassembly, convenient collection and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

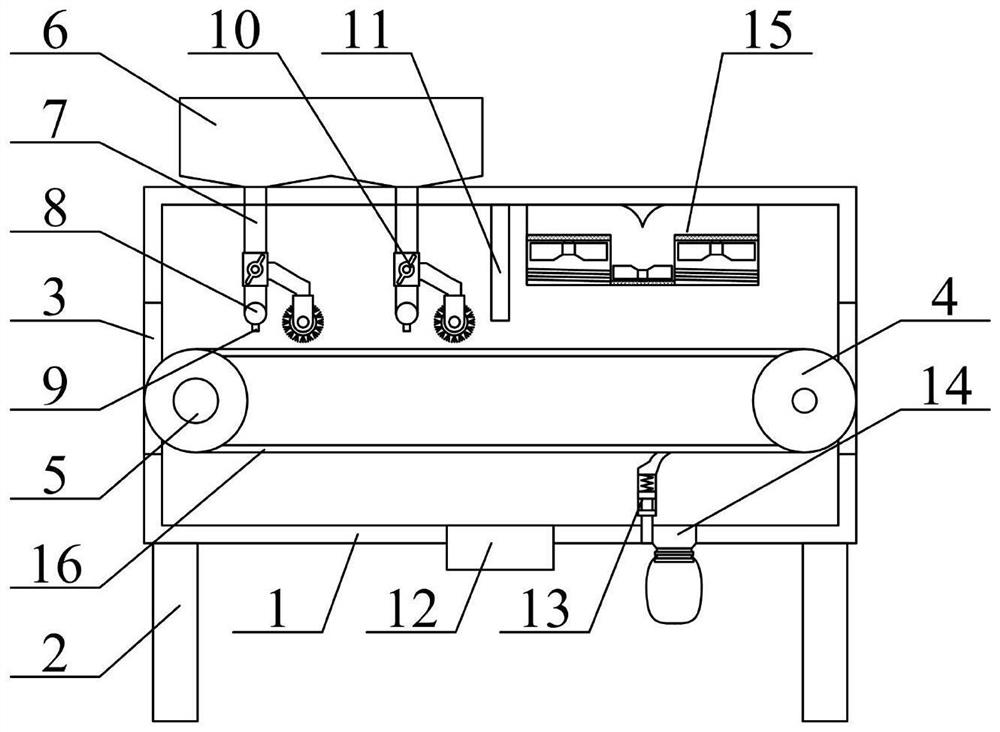

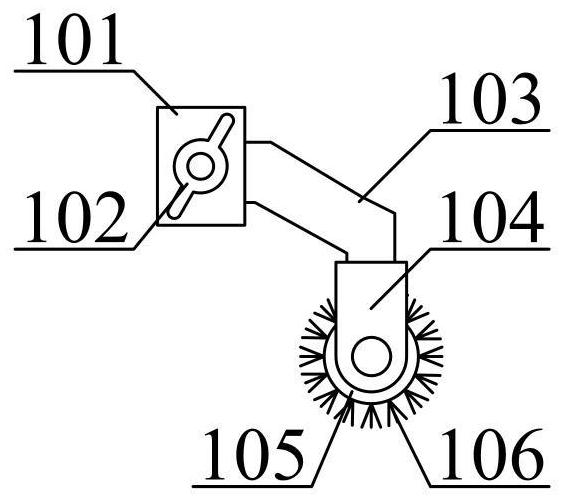

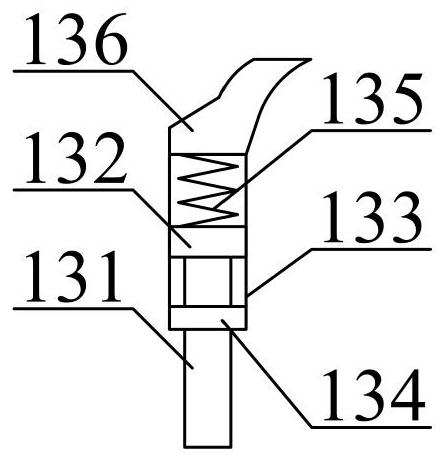

[0039] Append figure 1 Attach figure 2 Shown

[0040]The present invention provides an adjustable printing aluminum plate automatic deposition, including mounting frame 1, longitudinal bracket 2, conveying frame 3, rotary roller 4, conveying motor 5, storage box 6, longitudinal catheter 7, lateral catheter 8 The rubber head 9 is adjusted to the brush structure 10, the longitudinal baffle 11, the discharge tube 12, the buffered frame structure 13, the waste collecting frame structure 14, the drying circulation structure 15, and the conveyor belt 16, the The longitudinal bracket 2 bolts are mounted at the lower quarters of the mounting frame 1; the conveying frame 3 is embedded in the left and right sides of the mounting frame 1; the rotary roller 4 is axially attached to the outer frame 1 On both sides; the conveying motor 5 bolts are mounted on the left side of the front portion of the mounting frame 1, and the output shaft of the transport motor 5 is connected to the center key o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com